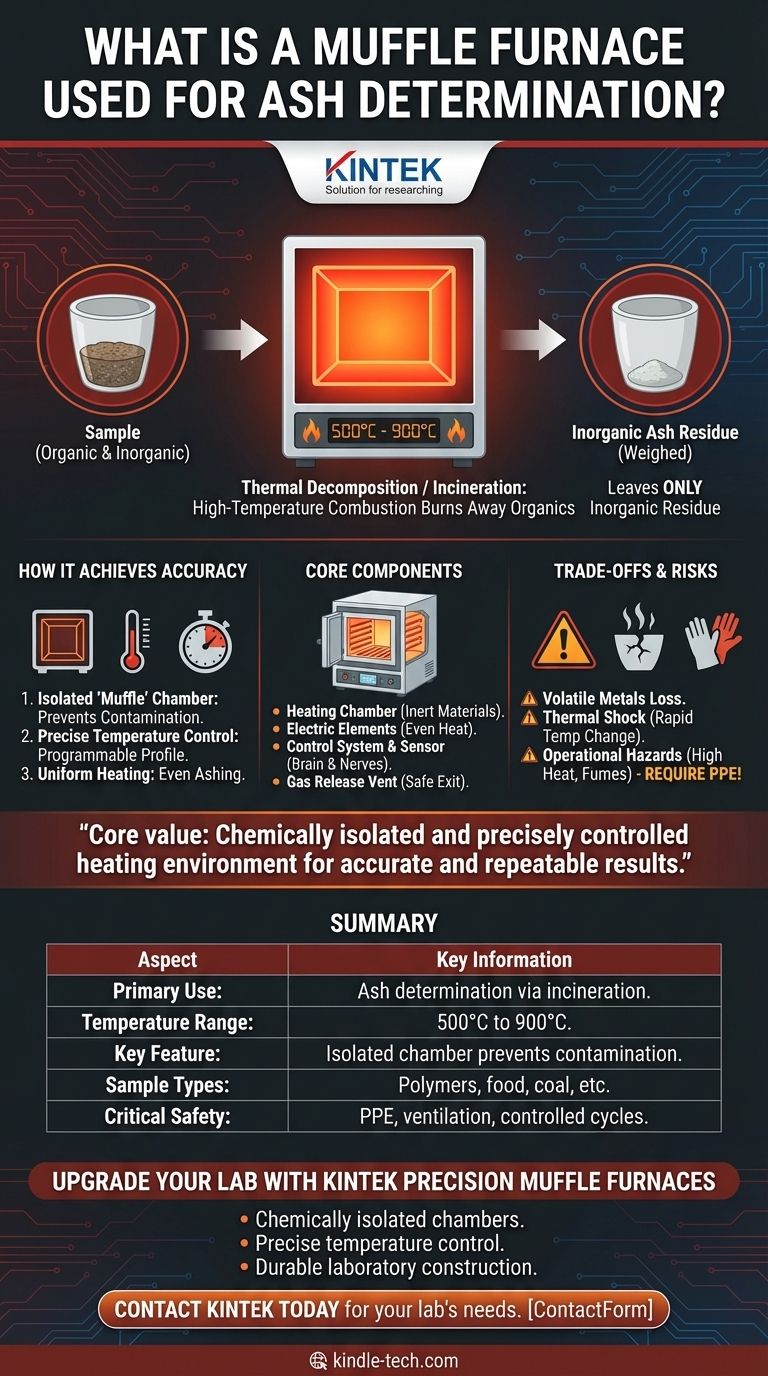

A muffle furnace is a specialized high-temperature oven used for ash determination because it can completely burn away the organic components of a sample in a clean, controlled environment. This process, known as incineration or ashing, leaves behind only the non-combustible inorganic residue (the ash), which can then be weighed to determine its percentage of the original sample. The furnace's key feature is an isolated chamber that prevents any combustion byproducts from the heat source from contaminating the sample.

The core value of a muffle furnace in ash analysis is its ability to provide a chemically isolated and precisely controlled heating environment. This ensures that the residue left after heating is purely the inorganic ash from the sample itself, leading to accurate and repeatable results.

How a Muffle Furnace Achieves Ash Determination

A muffle furnace operates on simple but powerful principles of thermal decomposition. Understanding how it works reveals why it is the standard instrument for this type of analysis.

The Principle of High-Temperature Combustion

To determine ash content, all organic matter in a sample must be removed. A muffle furnace achieves this by heating the sample to temperatures typically between 500°C and 900°C. At this extreme heat, carbon-based organic compounds react with oxygen in the air and are combusted, converting into gases like carbon dioxide and water vapor, which then exit the furnace.

The Critical Role of the "Muffle"

The term "muffle" refers to the furnace's insulated inner chamber, which is isolated from the heating elements. This design is critical. It prevents any gases, soot, or other impurities from the heating process itself from coming into contact with and contaminating the sample. Modern electric furnaces are exceptionally clean, using high-temperature elements to heat the chamber without introducing any combustion byproducts.

Precise and Uniform Temperature Control

Accurate ashing requires holding a specific temperature for a set duration. Muffle furnaces are equipped with precise temperature sensors (thermocouples) and a control panel. This allows operators to program a specific heating profile—a gradual ramp-up to the target temperature, a sustained "soak" time, and a controlled cool-down—ensuring consistent and repeatable conditions for every sample.

Core Components and Their Function

The effectiveness of a muffle furnace comes from the synergy of its core components.

The Heating Chamber

The internal chamber is constructed from inert, refractory materials like silica and high-purity alumina. These materials can withstand extreme temperatures without degrading or reacting with the sample.

Electric Heating Elements

These components are responsible for generating heat. They are strategically placed around the outside of the muffle chamber to provide even, radiant heat distribution, preventing hot spots and ensuring the entire sample is incinerated uniformly.

The Control System and Sensor

The control panel is the furnace's brain, while the temperature sensor is its nervous system. The sensor constantly monitors the internal temperature, feeding data to the controller, which adjusts power to the heating elements to precisely follow the programmed heating cycle.

The Gas Release Vent

As organic matter combusts, it produces gases. A small, controlled vent allows these gases to escape the chamber safely, preventing pressure buildup and ensuring the combustion process continues efficiently.

Understanding the Trade-offs and Risks

While highly effective, using a muffle furnace requires an understanding of its limitations and adherence to strict safety protocols.

Not Suitable for Volatile Metals

The primary limitation is that extremely high temperatures can cause certain inorganic elements or metallic compounds (like mercury or lead) to vaporize. If the sample contains volatile inorganics, this method can lead to an underestimation of the true ash content.

Risk of Thermal Shock

The ceramic materials in the furnace chamber and the sample crucibles are susceptible to thermal shock. Rapidly heating or, more commonly, rapid cooling can cause them to crack. This is why programmed, gradual temperature changes are essential for equipment longevity.

Significant Operational Hazards

Operating a device at nearly 1000°C presents obvious dangers. Severe burns can result from touching the furnace body or its contents. Proper personal protective equipment (PPE), including heat-resistant gloves and safety glasses, is non-negotiable. Furthermore, adequate ventilation is critical to safely remove potentially hazardous fumes produced during combustion.

Making the Right Choice for Your Goal

To use a muffle furnace effectively, align your procedure with your primary objective.

- If your primary focus is analytical accuracy: Use a slow, controlled heating and cooling program to prevent sample loss from spattering and to avoid thermal shock to your crucible.

- If your primary focus is safety and equipment longevity: Always wear appropriate PPE, never place flammable materials near the unit, and ensure the ventilation system is functioning correctly.

- If you are analyzing diverse materials (e.g., polymers, food, coal): Recognize that each material has a different optimal ashing temperature and duration; consult industry standards or run tests to establish the correct protocol.

By providing a clean, controlled, and high-temperature environment, the muffle furnace remains an indispensable tool for precise inorganic analysis across countless industries.

Summary Table:

| Aspect | Key Information |

|---|---|

| Primary Use | Ash determination through incineration of organic matter |

| Temperature Range | 500°C to 900°C |

| Key Feature | Isolated chamber prevents sample contamination |

| Sample Types | Polymers, food, coal, and other materials requiring inorganic analysis |

| Critical Safety | Requires PPE, proper ventilation, and controlled heating/cooling cycles |

Upgrade your laboratory's analytical capabilities with KINTEK's precision muffle furnaces. Our specialized lab equipment is designed to deliver accurate, repeatable ash determination results for industries ranging from food science to materials testing.

We provide:

- Chemically isolated heating chambers for contamination-free analysis

- Precise temperature control for consistent, reliable results

- Durable construction built for long-term laboratory use

Let our experts help you select the perfect furnace for your specific application. Contact KINTEK today to discuss your lab's needs and discover how our equipment can enhance your analytical processes.

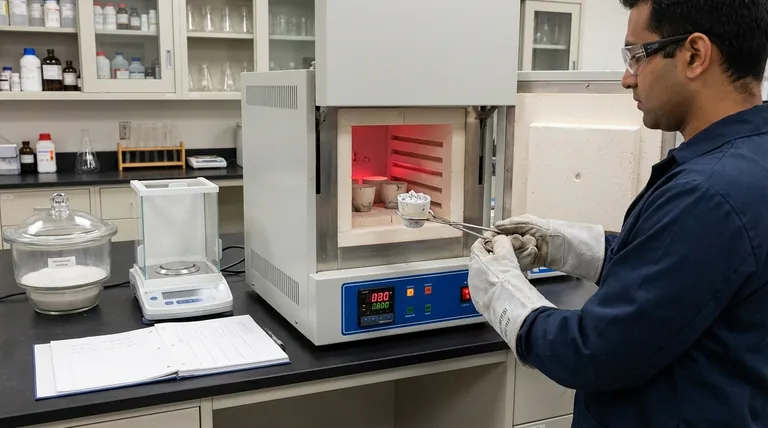

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the effect of calcination temperature on the properties of nanoparticles? Master the Trade-Off for Optimal Performance

- What is the effect of calcination? Unlock Material Transformation for Industrial Processes

- How do you perform calcination? Master Precise Thermal Treatment for Your Materials

- What is the importance of melting process? Master the Foundation of Metal Production

- What is the effect of temperature on calcination? Master Precise Heat Control for Material Properties