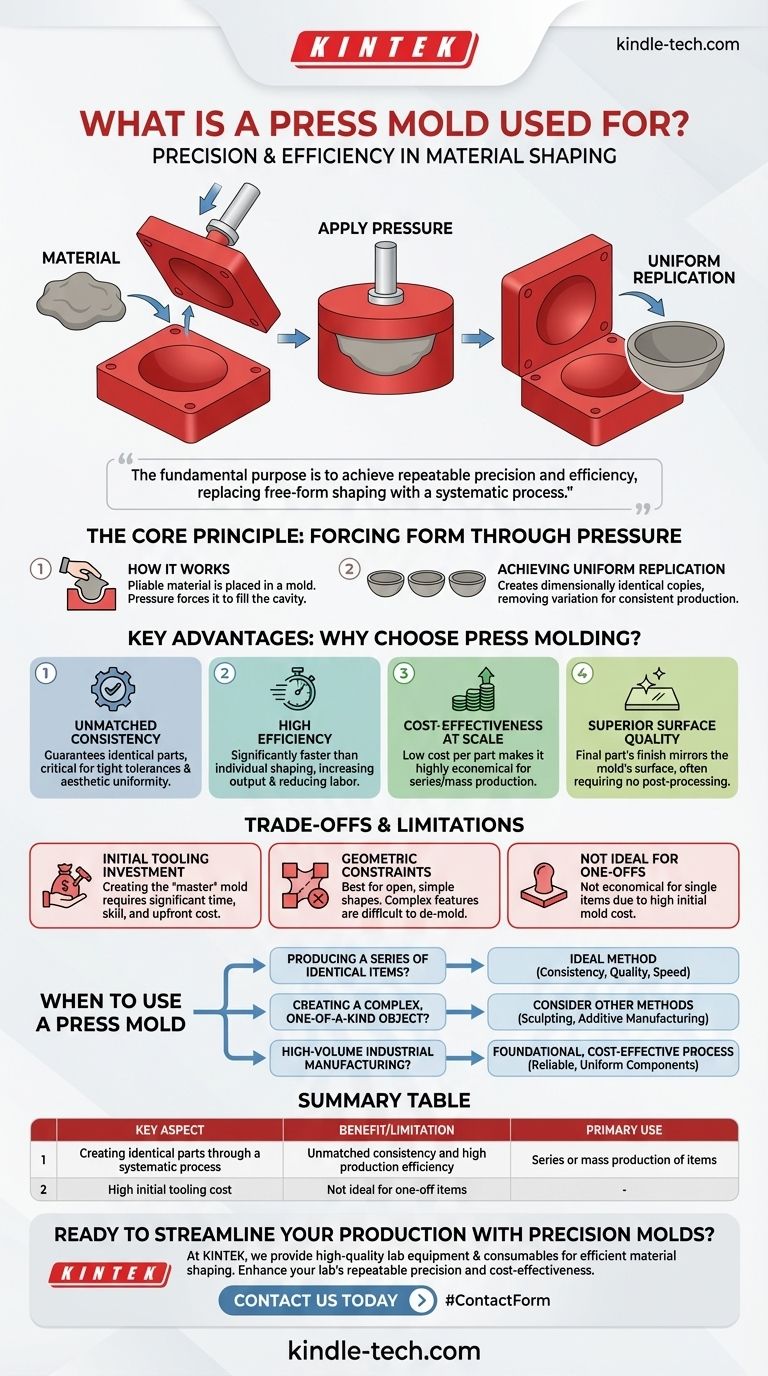

In craft and industrial production, a press mold is a rigid form used to shape a pliable material through the application of pressure. The material, such as clay or a composite, is forced into the mold's cavity, causing it to take on the mold's exact shape. Once the process is complete, the mold is removed to reveal a finished piece that is a uniform replication of the mold's interior.

The fundamental purpose of a press mold is to achieve repeatable precision and efficiency. It replaces free-form shaping with a systematic process, enabling the rapid and consistent production of identical parts.

The Core Principle: Forcing Form Through Pressure

How It Works

The mechanics of press molding are direct and effective. A pliable material is placed into a mold, and pressure is applied to force the material to fill every detail of the mold's cavity.

After the material has set or been compacted, the mold is carefully removed. The result is a part whose shape, texture, and dimensions are dictated by the mold itself.

Achieving Uniform Replication

The primary goal of using a press mold is to create one or many copies that are dimensionally identical. This process removes the variation inherent in hand-shaping.

Whether producing a set of matching ceramic bowls or thousands of industrial components, the mold ensures every single piece is a consistent and accurate clone of the original design.

Why Choose Press Molding? The Key Advantages

Unmatched Consistency

Unlike methods that rely on an operator's freehand skill, a press mold guarantees that each part will be the same. This is critical for applications requiring tight tolerances or aesthetic uniformity.

High Efficiency for Production

Once the mold is created, the process of producing parts is significantly faster than shaping each one individually. This dramatically increases output and reduces labor time per piece.

Cost-Effectiveness at Scale

As noted in processes like isostatic pressing, molds can have a very long service life. While there is an upfront investment in creating the mold, the low cost per part makes it highly economical for series or mass production.

Superior Surface Quality

The finish of the final part is a direct reflection of the mold's interior surface. A smooth, highly polished mold will produce a part with an equally high-quality finish, often requiring little to no post-processing.

Understanding the Trade-offs and Limitations

Initial Tooling Investment

Creating the initial "master" mold requires significant time, skill, and upfront cost. This tooling phase is the most resource-intensive part of the entire process.

Geometric Constraints

Press molding is best suited for open, relatively simple shapes. Designs with deep undercuts or extremely complex internal features can be difficult or impossible to de-mold without damaging the part or the mold itself.

Not Ideal for One-Offs

Because of the high initial investment in creating the mold, press molding is not economical for producing a single, unique item. Its value is realized through replication.

When to Use a Press Mold

Before choosing this method, evaluate your project's core requirements.

- If your primary focus is producing a series of identical items: A press mold is the ideal method for achieving consistency, quality, and speed.

- If your primary focus is creating a complex, one-of-a-kind object: A direct sculpting or additive manufacturing method would be more suitable than investing in mold creation.

- If your primary focus is high-volume industrial manufacturing: Press molding is a foundational, cost-effective process for creating reliable and uniform components.

By understanding its principles, you can leverage press molding to transform raw material into precise, repeatable forms with expert efficiency.

Summary Table:

| Key Aspect | Benefit/Limitation |

|---|---|

| Primary Use | Creating identical parts through a systematic process |

| Main Advantage | Unmatched consistency and high production efficiency |

| Best For | Series or mass production of items |

| Limitation | High initial tooling cost; not ideal for one-off items |

Ready to streamline your production with precision molds?

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including solutions for efficient material shaping and processing. Whether you are in R&D or full-scale manufacturing, our expertise can help you achieve the repeatable precision and cost-effectiveness your laboratory needs.

Contact us today to discuss how we can support your project with reliable equipment and expert consultation!

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Ball Press Mold for Lab

- Special Shape Press Mold for Lab

- Carbide Lab Press Mold for Laboratory Applications

- Round Bidirectional Press Mold for Lab

People Also Ask

- What is the physical role of graphite molds in vacuum hot pressing? Optimize Cu-Al2O3 Composite Densification

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?

- Is it fitting the mould or mold? A Guide to Correct Spelling by Region

- What is the core function of high-strength graphite molds? Master Vacuum Hot Press Sintering Efficiency

- Why are custom pressure molds used during the hot pressing process for solid polymer electrolytes?