In essence, a pusher furnace is a type of continuous industrial furnace. It processes materials by pushing them through various heating and cooling zones on a series of trays, boats, or plates. This creates a continuous train where a new boat entering the furnace pushes the entire line forward, allowing for consistent, high-volume production.

The critical distinction of a pusher furnace is its design for continuous operation, making it a cornerstone for high-throughput manufacturing processes. This contrasts sharply with batch furnaces, which process one discrete load at a time.

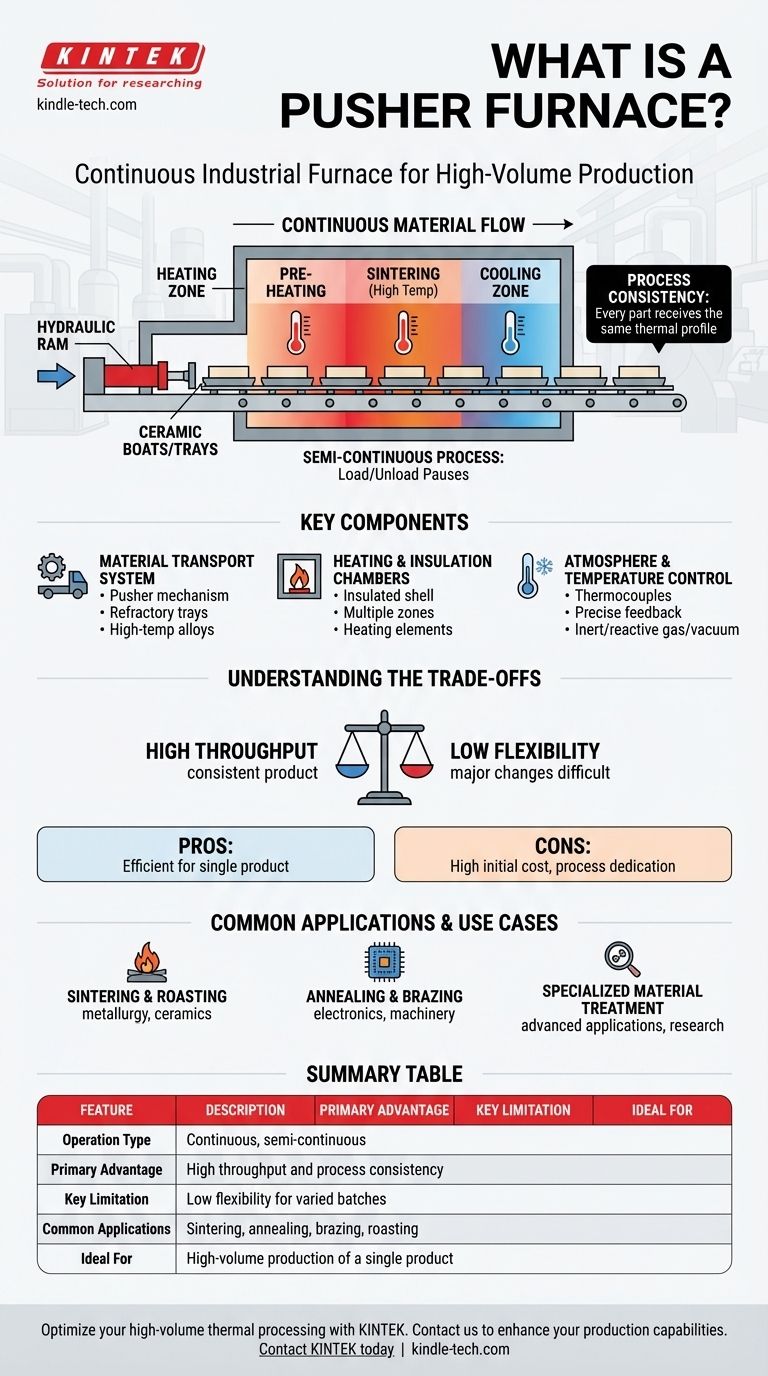

The Core Principle: Continuous Material Flow

The defining feature of a pusher furnace is its method of material transport. Understanding this mechanism is key to understanding its purpose and value in industrial settings.

How the "Push" Works

A mechanical system, often a hydraulic or electric ram, pushes a new tray of material into the furnace's entrance. This action forces the entire line of trays to move forward by one position.

The process is semi-continuous. The furnace pauses just long enough to unload a finished tray at the exit and load a new, unprocessed tray at the entrance before the next push occurs.

Achieving Process Consistency

This continuous flow ensures that every part is exposed to the same temperature profile for the same amount of time. The furnace is divided into distinct zones—pre-heating, sintering, and cooling—each with precise temperature control, guaranteeing a highly repeatable thermal process.

Key Components of a Pusher Furnace

While designs vary, pusher furnaces share a common set of functional components designed to manage the continuous thermal treatment of materials.

Material Transport System

This includes the boats or trays that carry the material and the pusher mechanism itself. The boats are typically made of refractory materials like ceramics or high-temperature alloys to withstand the extreme conditions.

Heating and Insulation Chambers

The furnace body consists of a heavily insulated shell containing multiple heating zones. These zones use heating elements like resistance wire, silicon carbide, or molybdenum disilicide to generate the required temperatures.

Atmosphere and Temperature Control

A sophisticated control system manages the entire process. It uses thermocouples for precise temperature feedback in each zone and can control the internal atmosphere, which might be inert gas, a reactive gas, or a vacuum, depending on the application.

Cooling Chambers

After passing through the high-temperature zones, materials move into cooling chambers. These chambers are designed to bring the product back to a safe handling temperature at a controlled rate to prevent thermal shock or unwanted microstructural changes.

Understanding the Trade-offs

A pusher furnace is a powerful tool, but it is not universally applicable. Its design advantages for some processes create limitations for others.

High Throughput vs. Low Flexibility

The primary benefit is high throughput for a consistent product. However, this same design makes it inflexible. Changing the temperature profile or processing time is a major undertaking, making it unsuitable for small, varied batches or experimental work.

Initial Cost and Complexity

The mechanical pusher system, extensive zoning, and complex control systems make these furnaces a significant capital investment. Their design is optimized for continuous or near-continuous operation to justify the cost.

Process Dedication

A pusher furnace is typically dedicated to a single, well-defined thermal process. Its efficiency is lost if it must be frequently stopped, cooled, and re-programmed for different materials or outcomes.

Common Applications and Use Cases

The ability to deliver consistent, high-volume heat treatment makes the pusher furnace essential across numerous industries for a wide range of thermal processes.

Sintering and Roasting

It is widely used in metallurgy and ceramics for sintering powdered materials into a solid mass. This includes applications for ceramic components, refractory materials, and powder metal parts.

Annealing and Brazing

In electronics and machinery, these furnaces are used for annealing metals to relieve internal stresses and for brazing components together in a controlled atmosphere.

Specialized Material Treatment

The precise control over temperature and atmosphere allows for advanced applications, such as firing electronic components, treating special materials, and conducting research in university and industrial labs.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on your production needs and operational goals.

- If your primary focus is high-volume, continuous production of a single product: A pusher furnace is the ideal solution for its efficiency and process repeatability.

- If your primary focus is research, small-batch production, or processing diverse materials with different thermal profiles: A batch or tube furnace offers far greater flexibility and lower initial cost.

Ultimately, choosing a pusher furnace is a commitment to a specific, high-scale manufacturing process where consistency is paramount.

Summary Table:

| Feature | Description |

|---|---|

| Operation Type | Continuous, semi-continuous |

| Primary Advantage | High throughput and process consistency |

| Key Limitation | Low flexibility for varied batches |

| Common Applications | Sintering, annealing, brazing, roasting |

| Ideal For | High-volume production of a single product |

Optimize your high-volume thermal processing with KINTEK.

Our pusher furnaces are engineered for maximum throughput and repeatability, making them the cornerstone of efficient production lines for sintering, annealing, and brazing. If your goal is consistent, high-volume manufacturing of materials like ceramics or powder metals, our expertise in lab equipment can provide the reliable thermal processing solution you need.

Contact KINTEK today to discuss how a pusher furnace can enhance your production capabilities.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What does a Rotavapor do? Achieve Gentle, Efficient Solvent Removal for Your Lab

- What are researchers trying to do to make biofuels cheaper? Unlock Affordable, Sustainable Energy with Advanced Bioengineering

- What are the parameters of magnetron sputtering process? Master Key Variables for Superior Thin Films

- What are the parts of a filter press machine? The 4 Core Components for Efficient Filtration

- Why pyrolysis is better than incineration? Transforming Waste into Valuable Resources

- What are the two advantages of using brazing when joining metal? Achieve Strong, Clean, and Complex Metal Assemblies

- What is a target in a sputtering process? The Source of Your Thin Film Coating

- Which is the most preferred material for manufacturing of a semiconductor? Silicon's Dominance Explained