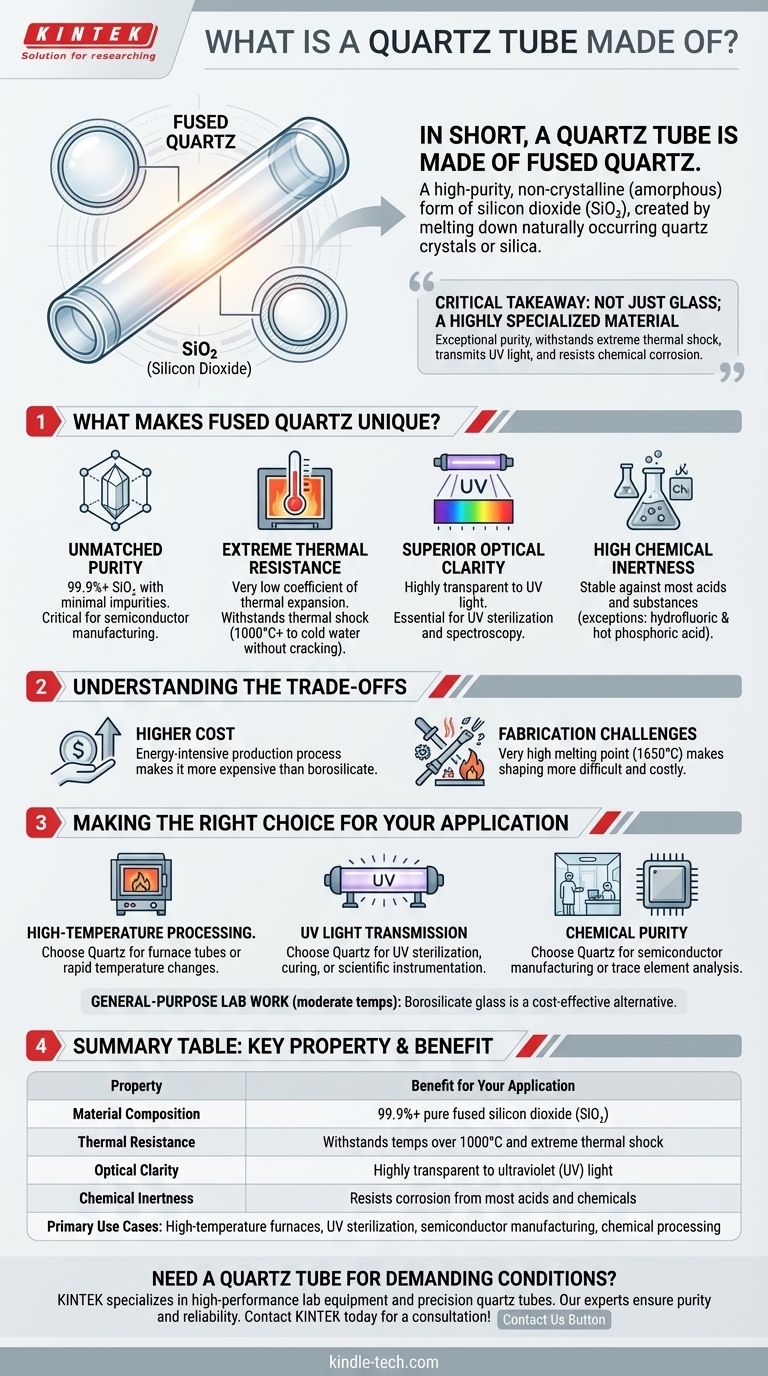

In short, a quartz tube is made of fused quartz. This is a high-purity, non-crystalline (amorphous) form of silicon dioxide (SiO₂), created by melting down naturally occurring quartz crystals or silica. Unlike standard glass, it is composed almost entirely of this single ingredient, which gives it a unique set of properties essential for demanding technical applications.

The critical takeaway is that a quartz tube is not just a type of glass; it is a highly specialized material. Its value comes from its exceptional purity and ability to withstand extreme thermal shock, transmit ultraviolet light, and resist chemical corrosion where conventional materials would fail.

What Makes Fused Quartz Unique?

The choice of fused quartz is deliberate and driven by properties that are impossible to achieve with standard glass, such as borosilicate. These characteristics stem directly from its simple and pure chemical structure.

Unmatched Purity

A quartz tube is one of the purest materials available for industrial and scientific use. It is typically composed of 99.9%+ silicon dioxide (SiO₂) with minimal impurities.

This high purity is critical in applications like semiconductor manufacturing, where even trace amounts of contaminants can ruin microchips.

Extreme Thermal Resistance

Fused quartz has an extremely low coefficient of thermal expansion. This means it barely expands or contracts when its temperature changes dramatically.

You can heat a quartz tube to over 1000°C and then plunge it into cold water without it cracking. This resistance to thermal shock is one of its most important features, making it ideal for high-temperature furnace tubes and lab equipment.

Superior Optical Clarity

Unlike most types of glass, fused quartz is highly transparent to ultraviolet (UV) light. Standard glass blocks most UV wavelengths.

This property makes quartz essential for applications like UV water sterilization lamps, UV curing processes, and various scientific instruments that rely on UV spectroscopy.

High Chemical Inertness

Fused quartz is chemically very stable and does not react with most acids, water, or neutral substances. The only notable exceptions are hydrofluoric acid and hot phosphoric acid.

This resistance to corrosion makes it an excellent choice for containers and tubing used to handle aggressive chemicals in laboratory settings.

Understanding the Trade-offs

While its properties are exceptional, fused quartz is not the default choice for every application. Understanding its limitations is key to making an informed decision.

Higher Cost

The process of melting and purifying natural quartz crystal into a usable form is energy-intensive and complex. As a result, quartz tubing is significantly more expensive than tubes made from borosilicate or other standard glasses.

Fabrication Challenges

Fused quartz has a very high melting point (around 1650°C), making it more difficult and costly to shape and work with than conventional glass. This limits the complexity of shapes that can be easily manufactured and increases the cost of custom fabrication.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the demands of your specific task.

- If your primary focus is high-temperature processing: Quartz is the superior choice for furnace tubes or any application involving rapid, extreme temperature changes.

- If your primary focus is UV light transmission: Quartz is non-negotiable for applications like UV sterilization, curing, or scientific instrumentation that requires UV transparency.

- If your primary focus is chemical purity: Quartz is essential for semiconductor manufacturing, trace element analysis, and other fields where contamination must be avoided at all costs.

- If your primary focus is general-purpose lab work at moderate temperatures: Borosilicate glass is often a more cost-effective and perfectly suitable alternative.

Ultimately, choosing a quartz tube is a decision to invest in unparalleled performance for conditions where other materials simply cannot operate.

Summary Table:

| Key Property | Benefit for Your Application |

|---|---|

| Material Composition | 99.9%+ pure fused silicon dioxide (SiO₂) |

| Thermal Resistance | Withstands temperatures over 1000°C and extreme thermal shock |

| Optical Clarity | Highly transparent to ultraviolet (UV) light |

| Chemical Inertness | Resists corrosion from most acids and chemicals |

| Primary Use Cases | High-temperature furnaces, UV sterilization, semiconductor manufacturing, chemical processing |

Need a Quartz Tube for Demanding Conditions?

Choosing the right material is critical for your lab's success. KINTEK specializes in high-performance lab equipment and consumables, including precision quartz tubes designed for extreme thermal and chemical environments. Our quartz tubes ensure the purity and reliability your applications demand.

Let our experts help you select the perfect solution for your specific needs. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

People Also Ask

- What specific capabilities must laboratory tube furnaces or muffle furnaces possess? Precision for 300 K to 600 K Heat

- How does a horizontal high-temperature tube furnace evaluate oxidation? Quantifying Coating Durability at 1100°C

- What role does a high-temperature tube atmosphere furnace play in Cr/CrxN conversion? Enhance Coating Durability

- What are the key functions of a laboratory tube furnace in perovskite studies? Mastering Atmospheric Stability Control

- What role does a cylindrical horizontal quartz tube furnace play in manganese coatings? Master Thermal Oxidation

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- Why is a tube furnace required for Se/PPS mercury removal? Optimize Thermal Control for Flue Gas Research

- Why is a combustion tube set to 1150 °C for asphaltene analysis? Unlock Precise Elemental Quantification