In essence, a three-zone furnace is a high-performance furnace that has three distinct heating sections arranged along its length, each of which can be controlled independently. Unlike a standard single-zone furnace, this design allows you to create highly customized temperature profiles, either for exceptional temperature uniformity over a large area or for a controlled temperature gradient.

The critical advantage of a three-zone furnace is not just more heat, but precise thermal control. It solves the inherent problem of heat loss at the ends of a furnace, enabling a level of uniformity and process flexibility that a single-zone design cannot achieve.

The Core Principle: Independent Heating Zones

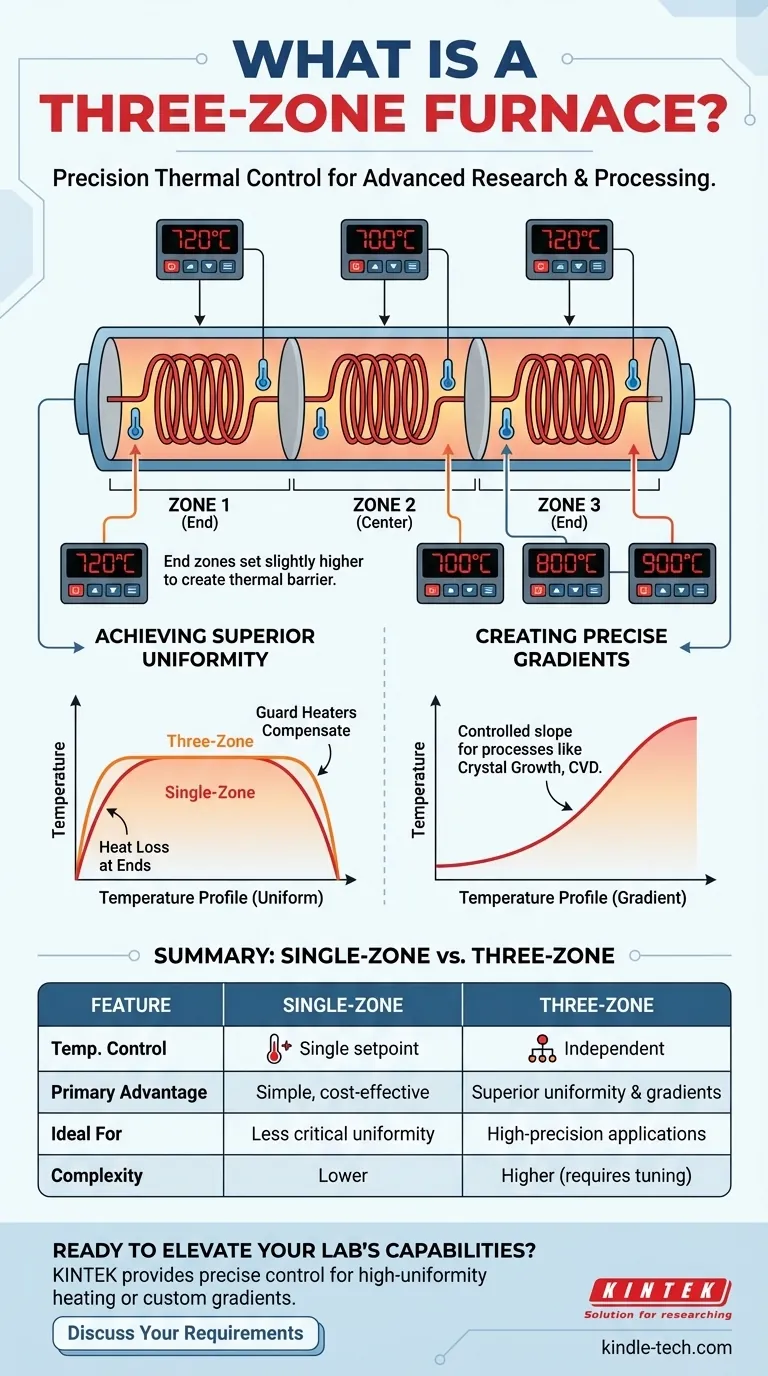

A typical furnace uses a single heating element and a single controller. A three-zone furnace elevates this design by dividing the heating chamber into three adjacent sections: a center zone and two end zones.

How It Works

Each of the three zones is equipped with its own set of heating elements and a dedicated temperature sensor (thermocouple). These are all connected to a sophisticated controller that can manage each zone as a separate entity.

This allows an operator to set a different temperature setpoint for each of the three zones simultaneously. The controller constantly monitors the temperature in each zone and adjusts the power to its heating elements to maintain the desired setpoints.

The Purpose of Independent Control

The ability to control each zone's temperature is the key to the furnace's utility. You can program the furnace to create complex thermal landscapes tailored to a specific process, a capability that is impossible with a single heating element.

Why Three Zones Are Often Necessary

The multi-zone design directly solves the fundamental limitations of single-zone furnaces, making them essential for high-precision thermal applications.

Achieving Superior Temperature Uniformity

In a single-zone furnace, heat naturally escapes from the ends. This unavoidable heat loss means the temperature at the center of the furnace will always be hotter than the temperature near the openings.

A three-zone furnace solves this by using the two end zones as "guard" heaters. By setting the temperature of the end zones slightly higher than the center, you can create a thermal barrier that actively compensates for heat loss. This forces the central zone to become exceptionally uniform in temperature across a much longer length.

Creating Precise Temperature Gradients

Some advanced processes, such as crystal growth or certain types of chemical vapor deposition (CVD), do not require a uniform temperature. Instead, they require a specific, controlled slope of temperature change across a material.

A three-zone furnace excels at this. You can, for example, set the first zone to 700°C, the middle to 800°C, and the third to 900°C to create a smooth and predictable temperature gradient along the length of the furnace tube.

Understanding the Trade-offs

While powerful, the three-zone design is not always the necessary choice. Understanding its complexities is key to making an informed decision.

Increased Complexity and Cost

The addition of two extra sets of heating elements, thermocouples, and the advanced multi-channel controller makes a three-zone furnace significantly more expensive and mechanically complex than a single-zone model.

Programming and Calibration

Achieving a perfectly flat temperature profile requires careful tuning. The interplay between the zones means you often need to experiment with the end zone setpoints to find the ideal values that deliver the desired uniformity in the center for your specific process temperature. This setup process is more involved than with a single-zone furnace.

Making the Right Choice for Your Process

Your choice between a single-zone and three-zone furnace should be driven entirely by the thermal precision your application demands.

- If your primary focus is maximum temperature uniformity over a large area: A three-zone furnace is the superior choice, as it is the only way to actively compensate for end-zone heat loss.

- If your primary focus is creating a controlled temperature gradient: A three-zone (or other multi-zone) furnace is essential, as this capability is impossible with a single heating element.

- If your primary focus is simple heating with a small, less-critical uniform zone: A single-zone furnace is often the more cost-effective and straightforward solution.

Ultimately, choosing a three-zone furnace is an investment in achieving a higher degree of control over your thermal process.

Summary Table:

| Feature | Single-Zone Furnace | Three-Zone Furnace |

|---|---|---|

| Temperature Control | Single setpoint for entire chamber | Independent setpoints for three sections |

| Primary Advantage | Simple, cost-effective heating | Superior uniformity & programmable gradients |

| Ideal For | Processes with less critical uniformity | High-precision applications like CVD, crystal growth |

| Complexity | Lower | Higher (requires tuning and calibration) |

Ready to elevate your lab's thermal processing capabilities?

A three-zone furnace from KINTEK provides the precise control you need for high-uniformity heating or custom temperature gradients. Whether your work involves advanced materials research, chemical vapor deposition (CVD), or crystal growth, our lab equipment is engineered for reliability and performance.

Let's discuss your specific application requirements. Contact our experts today to find the perfect furnace solution for your laboratory needs.

Visual Guide

Related Products

- Multi-zone Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a three-zone tube furnace used for the hydrolysis reaction in the Cu-Cl cycle? Optimize Thermal Control

- What role do high-temperature sintering or tube furnaces play in biomass catalysts? Engineering the Carbon Skeleton

- What role does a multi-stage zone refining furnace play in obtaining high-purity TlBr? Achieve Deep Material Purification

- What role does a vertical tube furnace play in alloy corrosion tests? Master Long-Term Atmospheric Control

- Why is a quartz material tube reactor selected for high-temperature steam cracking? Unlock Pure Kinetic Data

- What is the specific function of a high-temperature tube furnace in liquid lead corrosion exposure experiments? Guide

- Why are inert quartz glass tubes selected for pyrolysis corrosion testing? Ensure Data Integrity and Thermal Stability

- How do high-temperature tube furnaces maintain accuracy in sulfur oxide atmospheres? Ensure Precise Gas Control