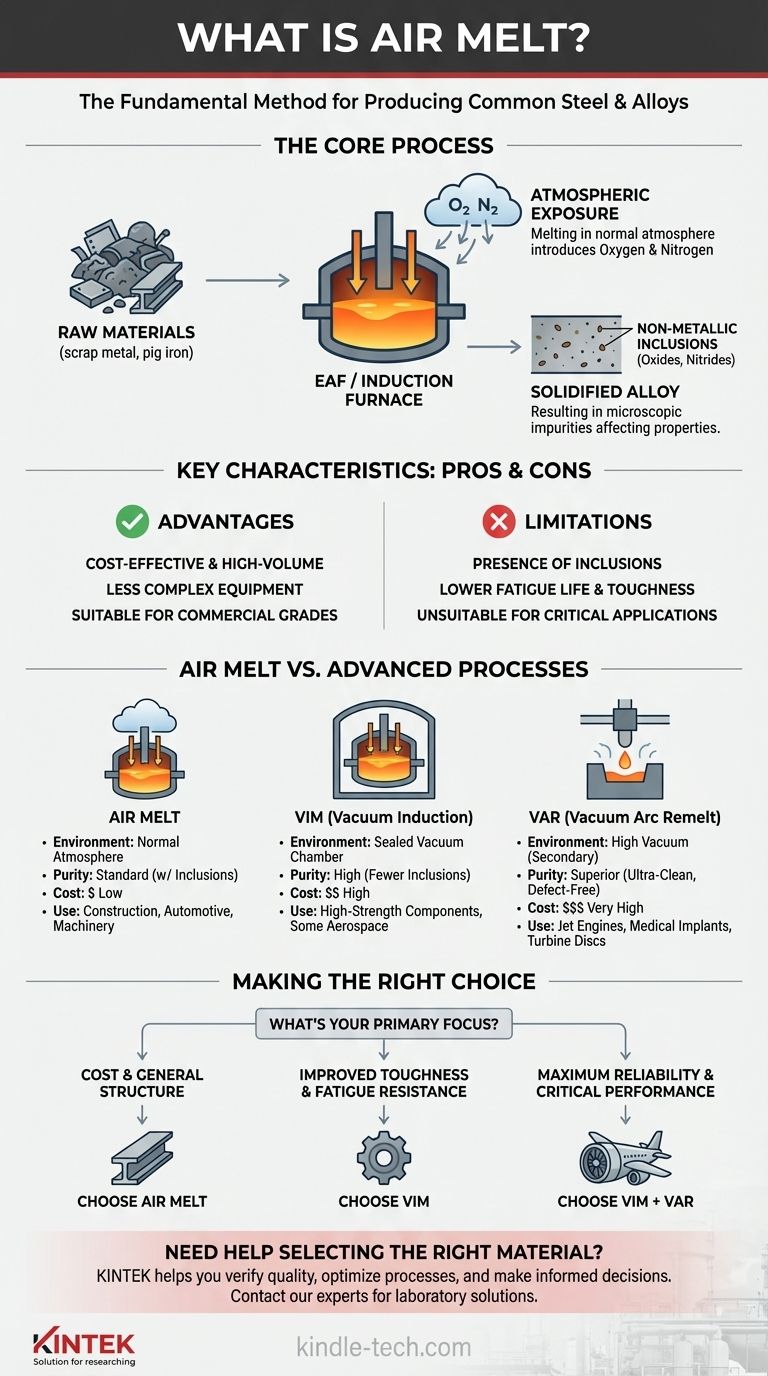

In metallurgy, "air melt" refers to the most fundamental and common method for producing steel and other alloys, where the melting process occurs in a furnace exposed to the normal atmosphere. This initial melting stage, typically done in an Electric Arc Furnace (EAF) or an Induction Furnace (IF), establishes the basic chemistry of the alloy but also introduces impurities from the surrounding air.

The central takeaway is that air melting is a cost-effective, high-volume production method suitable for a wide range of applications. However, its direct exposure to atmospheric gases inherently limits the material's purity and ultimate performance compared to more advanced vacuum melting techniques.

The Fundamentals of Air Melt Production

To understand the role of air-melted materials, it's essential to grasp the core process and its resulting characteristics. This primary melting practice is the foundation for the vast majority of steel produced globally.

The Core Process

The process begins by charging a furnace with raw materials, which can include scrap metal, pig iron, and specific alloying elements. Intense heat is then applied—either through a high-current electric arc (in an EAF) or electromagnetic induction (in an IF)—to melt the charge into a liquid state.

Throughout this process, the molten metal is in direct contact with the ambient air. This exposure is the defining characteristic of the air melt process.

Key Characteristics and Impurities

Because the melting occurs in the atmosphere, the molten metal readily reacts with atmospheric gases, primarily oxygen and nitrogen.

This interaction leads to the formation of non-metallic inclusions, such as oxides and nitrides, which become trapped within the solidified metal. These microscopic impurities can affect the steel's mechanical properties.

Common Alloys Produced

Air melting is the standard method for producing a vast array of common alloys where extreme purity is not a primary requirement.

This includes most carbon steels, low-alloy structural steels, many grades of stainless steel, and various tool steels. These materials form the backbone of construction, automotive manufacturing, and general industrial equipment.

Air Melt vs. Advanced Melting Processes

The limitations of air melt gave rise to more controlled, secondary processes designed to produce cleaner, higher-performance alloys. The key difference is the environment in which the metal is melted or remelted.

Vacuum Induction Melting (VIM)

VIM is also a primary melting process, but it is performed inside a sealed, vacuum-tight chamber. Melting the material in a vacuum prevents interaction with atmospheric gases and helps pull dissolved gases like oxygen and nitrogen out of the molten bath.

The result is a significantly cleaner and purer material than a standard air melt, with far fewer non-metallic inclusions.

Vacuum Arc Remelting (VAR)

VAR is a secondary refining process, not a primary one. It takes a previously melted material—often a high-quality air melt or VIM ingot—and uses it as a consumable electrode.

This electrode is remelted under a high vacuum via an electric arc, dripping into a water-cooled copper mold. This progressive solidification process further purifies the metal and creates a highly uniform internal structure, free from defects and residual impurities. VAR is used for the most demanding applications, like jet engine components and medical implants.

Understanding the Trade-offs of Air Melt

Choosing a material requires balancing performance requirements with economic reality. Air melting's position in the industry is defined by these trade-offs.

The Advantage of Cost-Effectiveness

Air melting is the most economical and efficient method for producing large quantities of steel. The equipment is less complex, and the process is faster than vacuum-based alternatives, making it ideal for commercial-grade materials.

The Limitation of Inclusions

The primary disadvantage is the presence of non-metallic inclusions. These microscopic impurities can act as stress concentrators, becoming potential initiation points for cracks. This limits the material's fatigue life and fracture toughness, especially in high-stress or cyclical loading conditions.

Unsuitability for Critical Applications

Because of the risk posed by inclusions, standard air-melted steel is not used for applications where failure would be catastrophic. Mission-critical aerospace components, high-performance bearings, surgical implants, and power generation turbine discs all require the higher purity guaranteed by secondary processes like VAR.

Making the Right Choice for Your Application

Selecting the appropriate melt process is a critical engineering decision that directly impacts performance, safety, and cost.

- If your primary focus is cost and general structural integrity: Air melt is the standard and most economical choice for applications like building frames, automotive bodies, and machinery.

- If your primary focus is improved toughness and fatigue resistance: A vacuum-degassed air melt or a primary VIM process provides a cleaner material suitable for high-strength gears or shafts.

- If your primary focus is maximum reliability and performance in extreme environments: A double or triple melt process (e.g., VIM followed by VAR) is non-negotiable for aerospace, medical, and defense applications.

Ultimately, matching the material's manufacturing process to the demands of the application is the foundation of sound engineering.

Summary Table:

| Aspect | Air Melt | Vacuum Induction Melting (VIM) | Vacuum Arc Remelting (VAR) |

|---|---|---|---|

| Process Environment | Normal atmosphere | Sealed vacuum chamber | High vacuum (secondary process) |

| Primary Use | Primary melting for common alloys | Primary melting for high-purity alloys | Secondary refining of premium alloys |

| Key Characteristic | Cost-effective, high-volume | High purity, fewer inclusions | Superior uniformity, defect-free structure |

| Typical Applications | Construction, automotive, machinery | High-strength components, some aerospace | Jet engine parts, medical implants, turbine discs |

| Relative Cost | Low | High | Very High |

Need help selecting the right material for your application?

Choosing between air-melted steel and advanced vacuum-melted alloys is critical for your project's performance, safety, and budget. KINTEK specializes in providing laboratory equipment and consumables essential for analyzing material properties, from basic composition to advanced inclusion analysis.

Our expertise helps you:

- Verify material quality and ensure it meets your application's demands.

- Optimize your processes with reliable lab equipment for precise testing and research.

- Make informed decisions by understanding the trade-offs between different manufacturing methods.

Let's discuss your specific laboratory needs. Contact our experts today to find the right solutions for your lab.

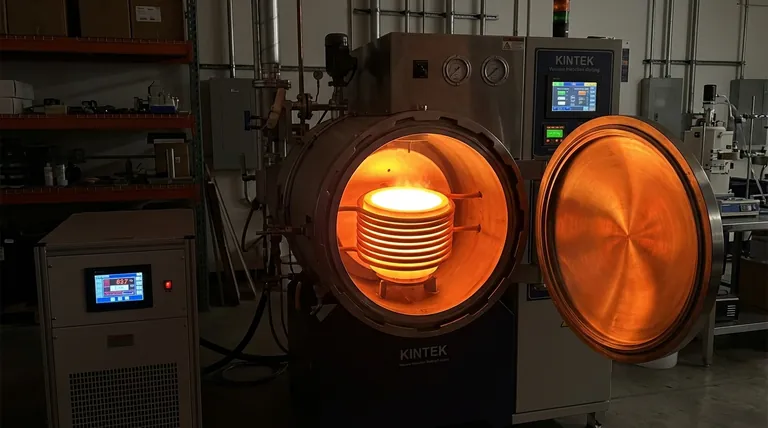

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does a high-speed stirring system contribute to the metal recovery rate? Maximize Zinc Sulfide Leaching Yields

- What is the process of gold sputtering? A Guide to High-Precision Thin Film Deposition

- What is the most common type of graphite? Natural Amorphous vs. High-Performance Synthetic

- How do precision dripping systems or syringes contribute to sodium alginate bead formation? Achieve Scientific Uniformity

- What heating treatment can be used to strengthen the structure of a metal? Master Hardening, Tempering & More

- How should frost be removed from Ultra-Low Temperature Freezers? Protect Your Samples and Equipment

- What is the difference between gas brazing and induction brazing? Choose the Right Brazing Method for Your Project

- What are the advantages of RF magnetron sputtering? Achieve Superior Thin Film Deposition for Insulating Materials