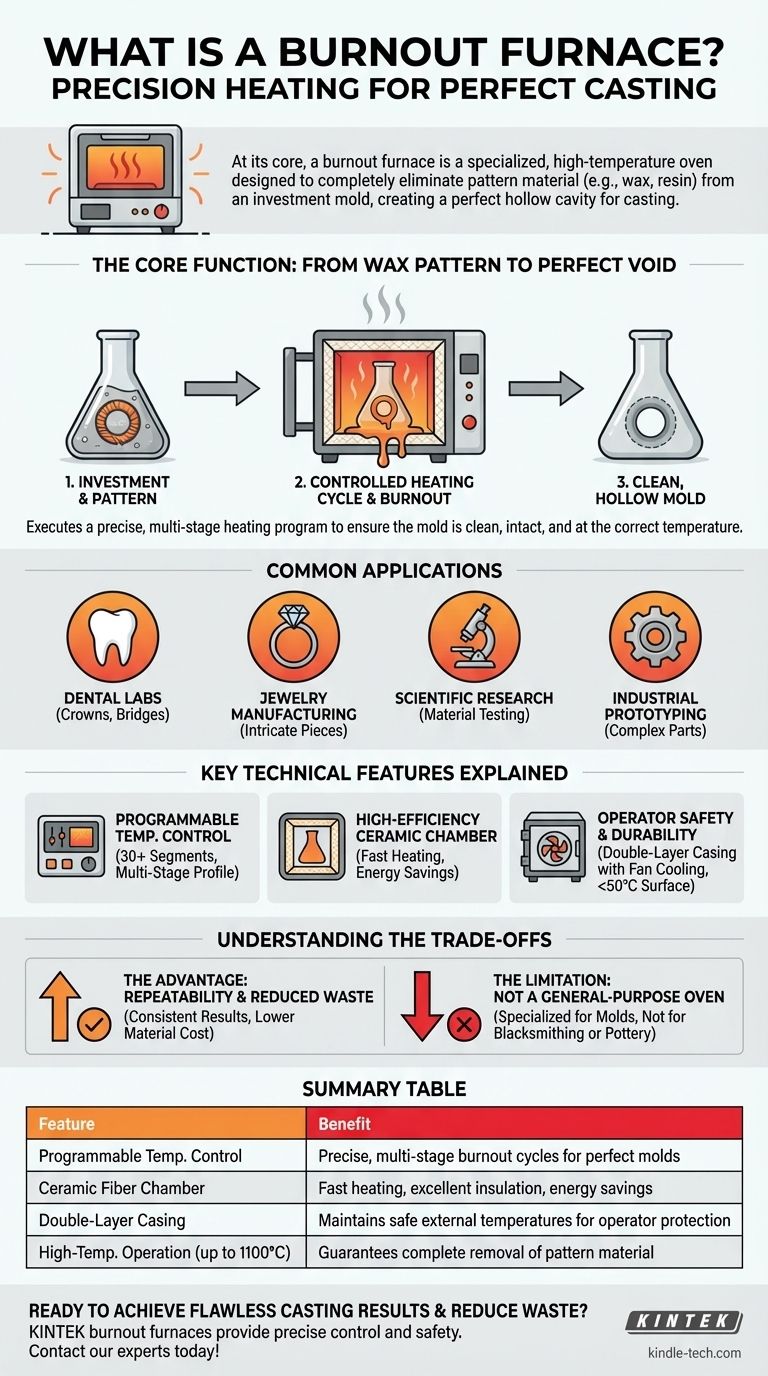

At its core, a burnout furnace is a specialized, high-temperature oven designed for a single critical task: to completely eliminate a pattern material, such as wax or 3D-printed resin, from an investment mold. This process, known as the "burnout cycle," creates a perfect, hollow cavity within the mold, which is then ready to be filled with molten metal or other materials during casting.

The primary purpose of a burnout furnace is not simply to generate heat, but to execute a precisely controlled heating program. This ensures the investment mold is perfectly prepared—clean, intact, and at the correct temperature—for a successful casting, minimizing material waste and production failures.

The Core Function: From Wax Pattern to Perfect Void

A burnout furnace is the heart of the investment casting process, also known as "lost-wax" casting. Understanding its function is key to appreciating its design.

What "Burnout" Actually Means

The process begins with a pattern (e.g., a wax model of a ring or a dental crown) that is surrounded by a liquid ceramic slurry called an "investment." Once the investment hardens, the entire assembly, called a flask, is placed in the burnout furnace.

The furnace then executes a carefully programmed heating cycle. In the initial stages, the wax melts and flows out. As the temperature climbs, any residual wax or resin is completely vaporized and burned away, leaving absolutely no residue.

Why Precision is Paramount

The success of the final cast depends entirely on the perfection of the burnout cycle. The furnace must provide uniform temperature and stable control throughout the chamber.

If heated too quickly, the expanding wax can crack the investment mold, leading to a failed cast. If the final temperature isn't high or long enough, residue can remain, causing defects in the final product.

Common Applications

Burnout furnaces are indispensable in fields that require high-precision cast parts. This includes:

- Dental Laboratories: For creating crowns, bridges, and partial denture frameworks.

- Jewelry Manufacturing: For casting rings, pendants, and other intricate pieces in precious metals.

- Scientific Research: For material testing and creating custom lab equipment.

- Industrial Prototyping: For producing small, complex metal parts.

Key Technical Features Explained

Modern burnout furnaces are engineered for precision, efficiency, and safety. Their features are not arbitrary; each one solves a specific problem in the casting process.

Programmable Temperature Control

These furnaces often feature 30 or more programmable segments. This isn't for convenience; it's essential for creating a multi-stage heating profile. A typical program includes a slow initial ramp to melt the wax, a hold to allow it to drain, a faster ramp to high temperature for burnout, and a final hold to ready the mold for casting.

High-Efficiency Chamber

The use of a ceramic fiber furnace chamber is a critical design choice. This lightweight material allows for very fast heating speeds and has excellent insulating properties.

This translates directly to shorter cycle times and significant energy savings, lowering the overall cost of production.

Operator Safety and Durability

Safety is a primary concern when working with temperatures up to 1100°C (2012°F). High-quality furnaces feature a double-layer steel casing with fan cooling.

This system actively dissipates heat, ensuring the exterior surface of the furnace remains below 50°C (122°F), protecting operators from burns and creating a safer working environment. This design also contributes to the equipment's long life.

Understanding the Trade-offs

While highly effective, it's important to understand the role and limitations of this specialized equipment.

The Advantage: Repeatability and Reduced Waste

The primary benefit of a quality burnout furnace is consistency. By perfectly executing the burnout cycle every time, it dramatically reduces the rate of failed castings.

This directly reduces the wastage of material (both the investment and the final casting metal) and lowers the overall cost of manufacturing.

The Limitation: Not a General-Purpose Oven

A burnout furnace is a specialist, not a generalist. Its heating profile and control systems are optimized for preparing investment molds.

It is generally not suitable for other high-temperature tasks like blacksmithing, large-scale heat treating, or pottery firing, which have different atmospheric and heating requirements. Using it for unintended purposes can be inefficient and yield poor results.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its capabilities to your specific application.

- If your primary focus is intricate dental or jewelry casting: Prioritize a furnace with highly precise, multi-stage programmable controls to protect delicate molds and ensure a flawless surface finish.

- If your primary focus is small-scale production or prototyping: Look for a model with excellent energy efficiency and documented temperature uniformity to minimize operating costs and ensure part-to-part consistency.

- If your primary focus is scientific research: Select a furnace with certified temperature accuracy and a wide operational range to guarantee repeatable and reliable experimental data.

Ultimately, a burnout furnace is the cornerstone of any precision investment casting workflow.

Summary Table:

| Feature | Benefit |

|---|---|

| Programmable Temperature Control | Ensures precise, multi-stage burnout cycles for perfect molds |

| Ceramic Fiber Chamber | Provides fast heating, excellent insulation, and energy savings |

| Double-Layer Steel Casing with Cooling | Maintains safe external temperatures for operator protection |

| High-Temperature Operation (up to 1100°C) | Guarantees complete removal of pattern material without residue |

Ready to achieve flawless casting results and reduce material waste?

A KINTEK burnout furnace provides the precise temperature control, uniform heating, and robust safety features essential for success in dental labs, jewelry manufacturing, and R&D. Our specialized lab equipment is engineered to deliver the repeatability your precision casting process demands.

Contact our experts today to find the perfect burnout furnace for your specific application and start optimizing your workflow.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why are high-precision vacuum sintering furnaces preferred over traditional methods for biofunctional dental ceramics?

- What is the function of a porcelain furnace? Precision Firing for Lifelike Dental Restorations

- What is the difference between VAR and VIM? Legacy Vimscript Variables vs. Modern Neovim API

- What is the advantage of firing porcelain in a vacuum? Achieve Denser, Stronger, and More Aesthetic Dental Restorations

- Why is a 1000°C+ furnace needed for LLZO/LLTO? Mastering High-Temperature Sintering for Ceramic Electrolytes