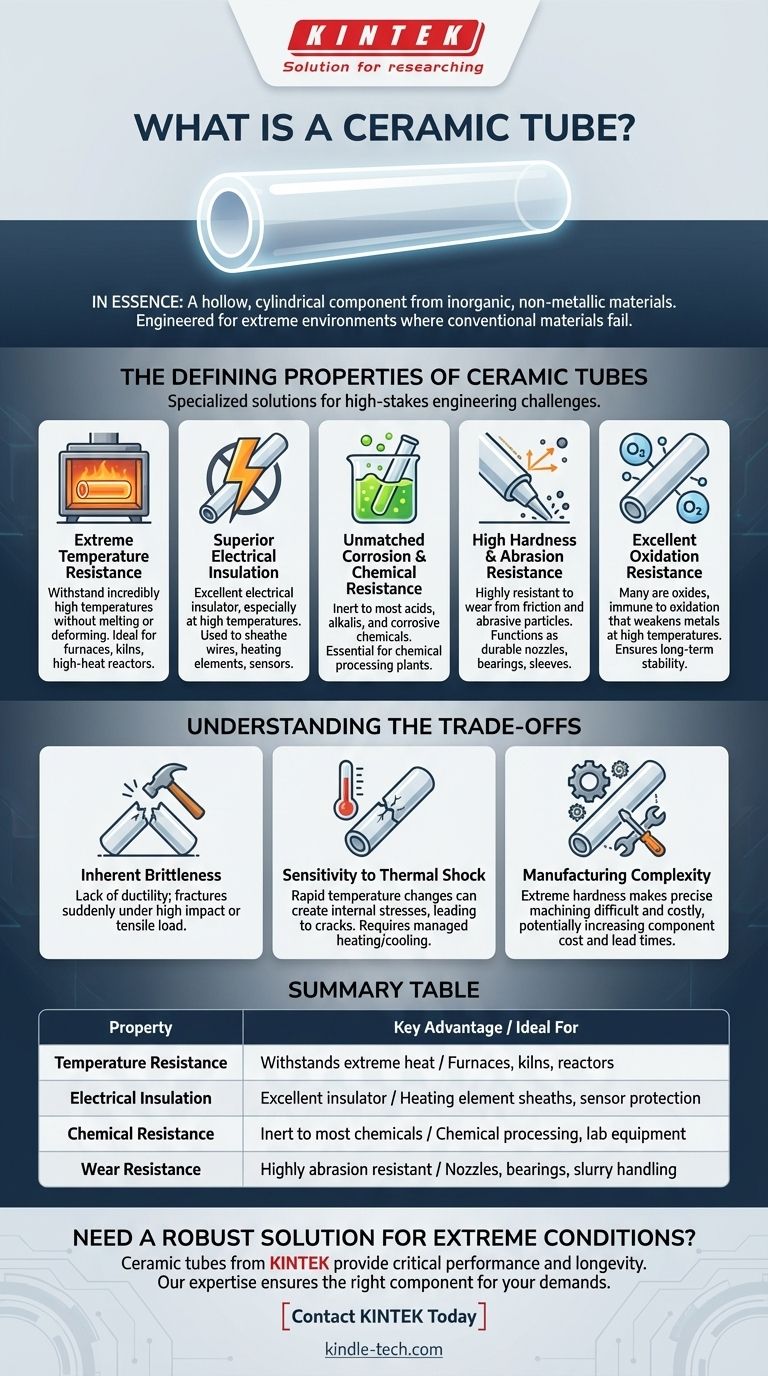

In essence, a ceramic tube is a hollow, cylindrical component engineered from inorganic, non-metallic materials. It is designed specifically to leverage the exceptional properties of ceramics—such as heat, corrosion, and wear resistance—in demanding applications where conventional materials like metal or plastic would rapidly fail.

The true value of a ceramic tube is not merely its shape, but its function as a robust barrier. It provides structural integrity, electrical insulation, or chemical containment in extreme environments that degrade or destroy other materials.

The Defining Properties of Ceramic Tubes

Understanding why you would choose a ceramic tube comes down to its fundamental material characteristics. These properties make it a specialized solution for high-stakes engineering challenges.

Extreme Temperature Resistance

Ceramics are defined by their ability to withstand incredibly high temperatures without melting, deforming, or losing structural integrity.

This makes them indispensable for components used inside furnaces, kilns, and high-temperature reactors where metals would soften and fail.

Superior Electrical Insulation

Unlike metals, most ceramics do not conduct electricity. This makes them perfect insulators, especially at elevated temperatures where the performance of plastic insulators degrades.

Ceramic tubes are frequently used to sheathe electrical wires, heating elements, and sensors, preventing short circuits in harsh thermal environments.

Unmatched Corrosion and Chemical Resistance

Ceramic materials are largely inert and do not react with most acids, alkalis, and other corrosive chemicals.

This property is critical for transporting aggressive fluids or for use as protective sheaths in chemical processing plants and laboratories where metal components would quickly corrode.

High Hardness and Abrasion Resistance

Ceramics are among the hardest materials available, making them highly resistant to wear from friction and abrasive particles.

This allows ceramic tubes to function as durable nozzles, bearings, or protective sleeves that handle abrasive slurries or high-velocity gas flows.

Excellent Oxidation Resistance

Many advanced ceramics are already oxides (like alumina), meaning they are immune to the oxidation that weakens metals at high temperatures.

This ensures long-term stability and reliability in high-heat, oxygen-rich environments.

Understanding the Trade-offs

While their properties are exceptional, ceramic tubes are not a universal solution. Their limitations are just as important to understand as their strengths.

Inherent Brittleness

The most significant drawback of ceramics is their lack of ductility. Unlike metal, which will bend or deform under stress, a ceramic tube will fracture suddenly if subjected to high impact or tensile load.

Sensitivity to Thermal Shock

Rapid and extreme temperature changes can create internal stresses that cause a ceramic tube to crack. Applications must be designed to manage heating and cooling rates to avoid this phenomenon, known as thermal shock.

Manufacturing and Machining Complexity

The extreme hardness that makes ceramics wear-resistant also makes them difficult and costly to machine into precise final shapes. This can lead to higher component costs and longer lead times compared to metal parts.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary engineering goal.

- If your primary focus is extreme temperature stability: A ceramic tube is often the only viable option, providing reliable performance in environments far beyond the limits of metals.

- If you need robust electrical insulation in a harsh environment: Ceramic tubes offer an unparalleled combination of dielectric strength, chemical inertness, and high-temperature resistance.

- If your application involves high impact or mechanical shock: You must carefully evaluate the inherent brittleness of ceramics and may need to explore specialized composites or reconsider a metallic alloy.

Ultimately, choosing a ceramic tube is a decision to prioritize performance and longevity in conditions too extreme for conventional materials.

Summary Table:

| Property | Key Advantage | Ideal For |

|---|---|---|

| Temperature Resistance | Withstands extreme heat without deforming | Furnaces, kilns, reactors |

| Electrical Insulation | Excellent insulator, even at high temperatures | Heating element sheaths, sensor protection |

| Chemical Resistance | Inert to most acids, alkalis, and corrosive agents | Chemical processing, lab equipment |

| Wear Resistance | Highly resistant to abrasion and friction | Nozzles, bearings, abrasive slurry handling |

Need a robust solution for extreme conditions?

Ceramic tubes from KINTEK provide the critical performance and longevity your laboratory or industrial process demands. Our expertise in advanced lab equipment ensures you get the right ceramic component for high-temperature, corrosive, or abrasive environments.

Contact KINTEL today to discuss how our ceramic tubes can enhance the reliability and efficiency of your application.

Visual Guide

Related Products

- High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why does the use of alumino-silicate refractories pose a problem in high-temperature hydrogen atmospheres?

- How hot can you heat ceramic? From Pottery to 2700°C with Advanced Materials

- Are ceramics chemically resistant? Unlock Their Power for Demanding Applications

- What is the new technology for veneers? Discover the Digital Revolution for a Perfect Smile

- How are ceramics used in medicine? Unlocking Biocompatible Implants for Long-Term Health

- What is the temperature range of a ceramic tube? Select the Right Material for Your High-Temp Needs

- Do ceramics have corrosion resistance? Leverage Their Inert Nature for Demanding Applications

- What are the characteristics of sintered ceramics? Achieve High-Performance with Engineered Materials