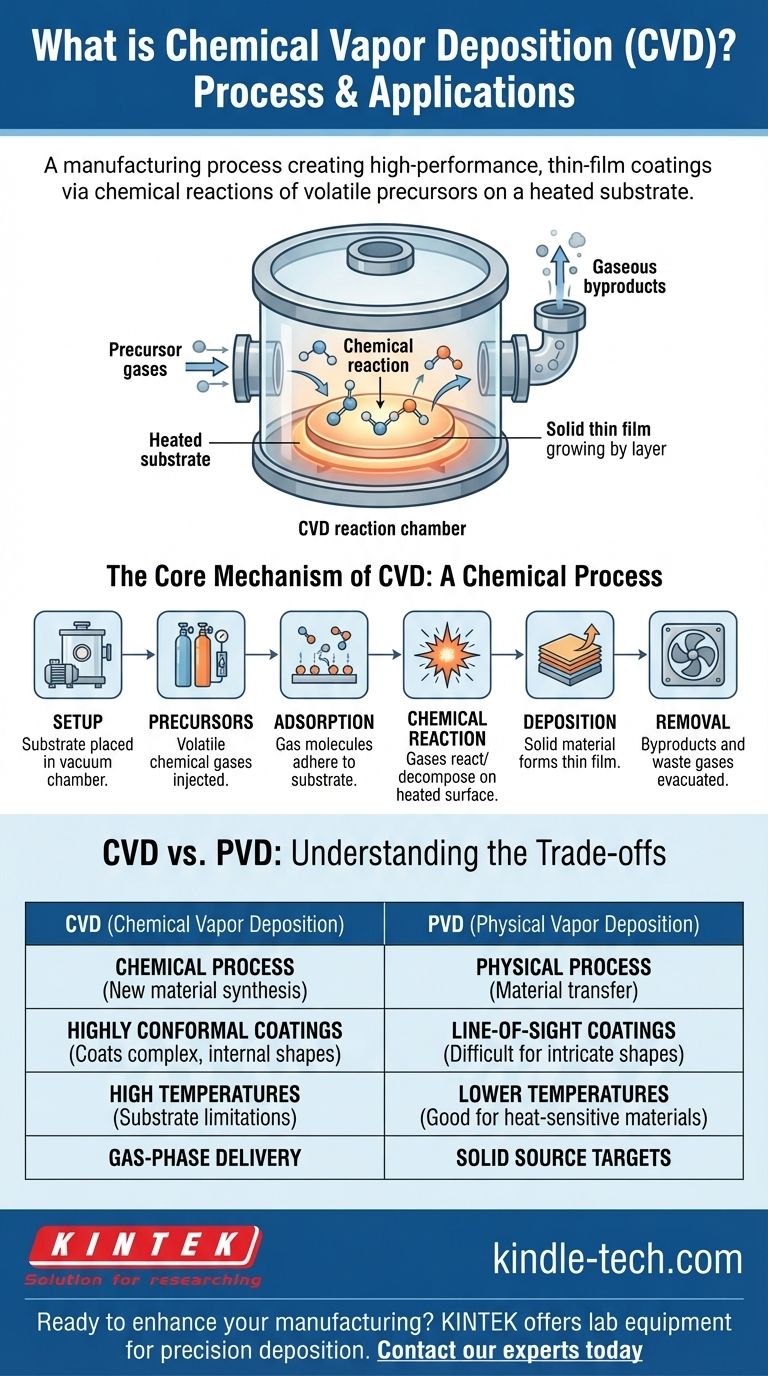

In short, Chemical Vapor Deposition (CVD) is a manufacturing process that creates a high-performance, thin-film coating on a substrate. It works by introducing volatile chemical gases, known as precursors, into a reaction chamber. These gases then react or decompose on a heated surface, forming a solid material that deposits evenly onto the target object, building the coating one layer of molecules at a time.

The core principle to understand is that CVD is fundamentally a chemical process, not a physical one. Unlike methods that simply move a material from a source to a target, CVD synthesizes an entirely new solid material directly on the component's surface through controlled chemical reactions.

The Core Mechanism of CVD

To truly grasp the CVD process, it's best to break it down into its sequential steps. The entire operation takes place within a sealed reaction chamber under carefully controlled temperature, pressure, and vacuum conditions.

The Setup: Chamber and Precursors

The process begins by placing the object to be coated, known as the substrate, inside a reaction chamber. The chamber is then evacuated to create a vacuum. Special volatile chemical compounds, called precursors, are selected based on the desired final coating material.

Step 1: Introducing the Precursors

The precursor chemicals, which are in a gaseous state, are precisely injected into the vacuum chamber. The flow rate and mixture of these gases are critical variables that control the final properties of the coating.

Step 2: Transport and Adsorption

Once inside the chamber, the precursor gas molecules travel and come into contact with the substrate. The molecules then physically stick to the surface in a process known as adsorption.

Step 3: The Chemical Reaction

This is the heart of the CVD process. The substrate is typically heated to a specific reaction temperature. This thermal energy provides the activation energy needed for the adsorbed precursor gases to react with each other or decompose directly on the surface.

Step 4: Deposition and Film Growth

The product of this chemical reaction is the desired solid coating material. This nonvolatile solid deposits onto the substrate, forming a stable, thin film. The process continues as more gas is supplied, allowing the film to grow in a highly uniform and controlled manner.

Step 5: Removing the Byproducts

The chemical reactions also create gaseous byproducts that are not part of the final coating. These waste gases are desorbed from the surface and are continuously removed from the chamber by the vacuum system, ensuring a pure and high-quality film.

Understanding the Trade-offs: CVD vs. PVD

To understand the specific advantages of CVD, it is helpful to contrast it with another common thin-film deposition technique: Physical Vapor Deposition (PVD).

The Fundamental Difference: Chemical vs. Physical

The primary distinction is in the name. CVD uses a chemical reaction on the substrate's surface to create the coating. In contrast, PVD uses a physical mechanism—such as evaporation or sputtering—to move atoms of the coating material from a solid source directly onto the substrate. There is no chemical transformation in PVD.

Coating Characteristics

Because CVD relies on a gas that can flow and permeate, it excels at creating highly conformal coatings, meaning it can uniformly cover complex shapes, sharp corners, and even internal surfaces. PVD is typically a "line-of-sight" process, which can make it difficult to coat intricate geometries evenly.

Process Conditions

CVD processes generally require high temperatures to provide the energy needed to drive the chemical reactions. This can limit the types of substrate materials that can be coated without being damaged. PVD can often be performed at much lower temperatures, making it suitable for more heat-sensitive materials.

Making the Right Choice for Your Goal

Selecting the correct deposition method depends entirely on the specific requirements of your application, including the material properties, substrate shape, and temperature constraints.

- If your primary focus is a high-purity, uniform coating on a complex shape: CVD is an exceptionally strong candidate due to the nature of its gas-phase delivery.

- If your primary focus is coating a temperature-sensitive material: PVD is often the better choice because it can be operated at significantly lower process temperatures than most CVD methods.

- If your primary focus is a specific material composition: The choice depends on the availability of suitable volatile precursors for CVD versus solid targets for PVD for that particular material.

Ultimately, understanding CVD as a precision chemical reaction process is the key to leveraging its unique capabilities for advanced material fabrication.

Summary Table:

| CVD Process Step | Key Action | Outcome |

|---|---|---|

| 1. Setup | Substrate placed in vacuum chamber | Prepares surface for coating |

| 2. Gas Introduction | Precursor gases injected into chamber | Delivers coating materials |

| 3. Adsorption | Gas molecules stick to substrate surface | Creates foundation for reaction |

| 4. Chemical Reaction | Gases react/decompose on heated surface | Forms solid coating material |

| 5. Deposition | Solid material builds up layer by layer | Creates uniform thin film |

| 6. Byproduct Removal | Waste gases evacuated from chamber | Ensures coating purity |

Ready to enhance your manufacturing with precision coatings? KINTEK specializes in lab equipment and consumables for advanced deposition processes like CVD. Our solutions help laboratories achieve superior thin-film results with high uniformity and purity. Contact our experts today to discuss how we can support your specific application needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition