In essence, chemical vapor deposition (CVD) for polymers is a process that builds a thin, solid polymer coating onto a surface directly from a gas. Instead of applying a liquid polymer, this technique introduces one or more precursor gases (monomers) into a vacuum chamber, where they react and chemically bond to the target object, forming a highly pure and uniform polymer film from the bottom up.

The core advantage of polymer CVD isn't just creating a coating, but creating one that is fundamentally different from those made by liquid methods. It allows for ultra-thin, perfectly conforming, and exceptionally pure films on complex shapes, which is impossible to achieve by simply painting or dipping.

The Core Principle: Building from Gas

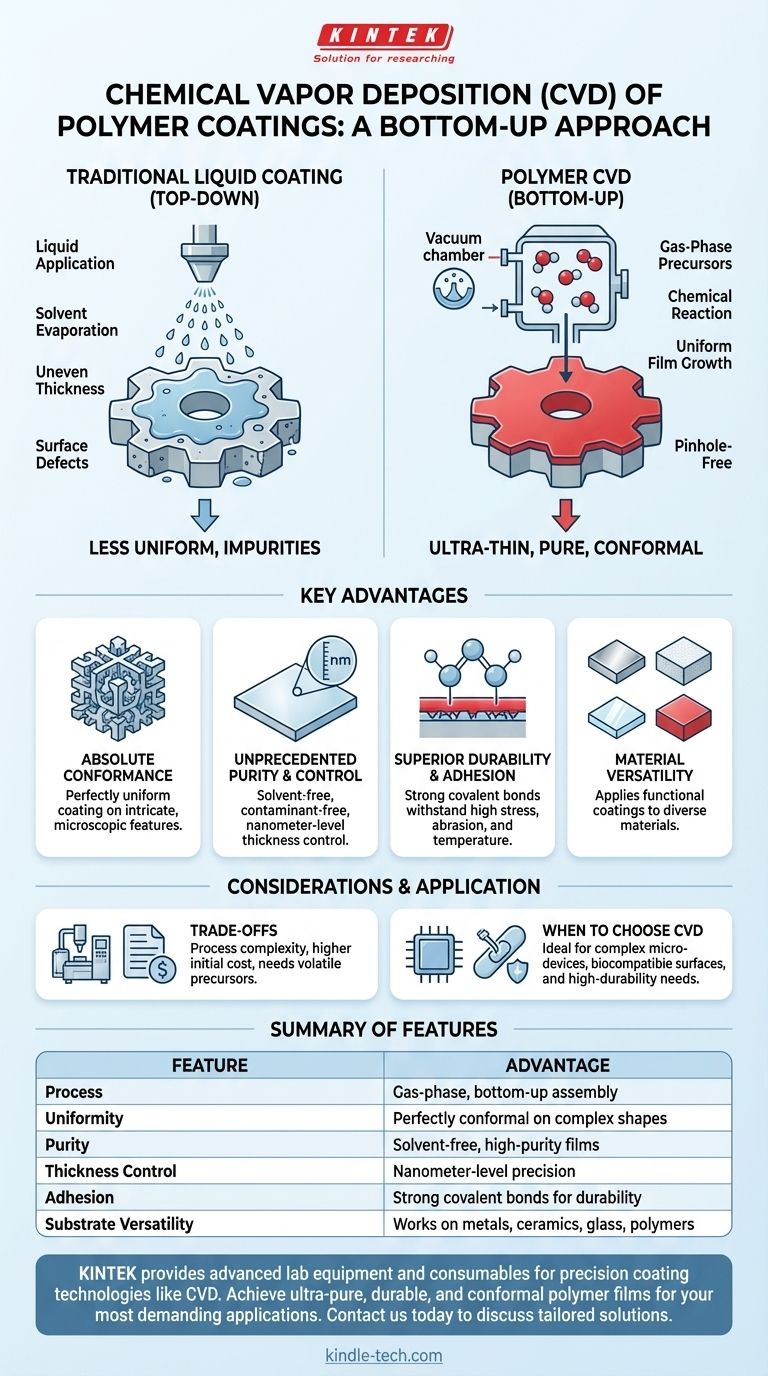

The power of CVD lies in its "bottom-up" assembly process, which is fundamentally different from traditional "top-down" methods like spraying or dip-coating.

How It Works

The process involves introducing carefully selected precursor gases into a low-pressure chamber containing the object to be coated (the substrate).

These gases are then activated, typically by heat, causing them to undergo a chemical reaction directly on the substrate's surface. This reaction builds a solid polymer film, molecule by molecule.

Because the film is constructed from a gas, it can penetrate and uniformly coat even the most complex, microscopic, or non-line-of-sight features of an object.

The Contrast with Liquid Coatings

Liquid-based coatings rely on a solvent or carrier that must evaporate, which can leave behind impurities, create surface tension defects like pinholes, and result in uneven thickness, especially in corners or on intricate parts.

CVD bypasses these issues entirely by operating in a clean, solvent-free vacuum environment, resulting in a denser and more perfect film.

Key Advantages of Polymer CVD

This gas-phase approach provides a unique set of benefits that are critical for high-performance applications.

Absolute Conformance on Complex Surfaces

Since gas molecules can reach any exposed surface, CVD creates a polymer layer of perfectly uniform thickness. This is essential for coating complex items like medical implants, electronic components, or micro-electromechanical systems (MEMS).

Unprecedented Purity and Control

The vacuum environment and high-purity precursor gases mean the resulting polymer film is free from solvents, additives, or contaminants.

Furthermore, the process allows for nanometer-level control over the final thickness, making it possible to create the ultra-thin functional layers required in optics and electronics.

Superior Durability and Adhesion

The chemical reactions in CVD can form strong covalent bonds between the polymer coating and the substrate material.

This results in a highly durable coating that adheres exceptionally well, capable of withstanding high stress, abrasion, and extreme temperature variations without delaminating.

Material Versatility

CVD is not limited to a single type of substrate. The process can be adapted to apply functional polymer coatings to a wide range of materials, including metals, ceramics, glass, and even other polymers.

Understanding the Trade-offs

While powerful, CVD is a specialized technique with specific considerations. It is not a universal replacement for all coating methods.

Process Complexity and Equipment Cost

CVD requires sophisticated equipment, including vacuum chambers, precision gas flow controllers, and temperature management systems. This makes the initial setup more complex and costly than traditional liquid coating lines.

Material Limitations

The biggest limitation is the need for suitable volatile precursors. The desired polymer must be formable from monomer gases that can be synthesized, handled safely, and induced to react under manageable process conditions. Not all polymers have viable CVD pathways.

Distinguishing from Physical Vapor Deposition (PVD)

It's important not to confuse CVD with PVD. In PVD, a solid material is vaporized (e.g., evaporated or sputtered) and physically transported to the substrate.

In CVD, the material is built on the substrate via a new chemical reaction. This distinction is critical, as PVD is typically used for metals and hard ceramics, while polymer CVD is a specialized field focused on organic functional films.

When to Choose Polymer CVD

Your choice of coating technology must align directly with your end goal. Polymer CVD is a high-value solution for problems that cannot be solved with conventional methods.

- If your primary focus is coating complex micro-devices or electronics: CVD is ideal for creating uniform, pinhole-free insulating or passivation layers on intricate topographies.

- If your primary focus is creating ultra-pure biocompatible surfaces: CVD provides a solvent-free method to functionalize medical implants or labware, ensuring a high-purity surface that won't leach contaminants.

- If your primary focus is durability in harsh environments: The strong adhesion and dense, defect-free nature of CVD films make them superior for protecting sensitive components from corrosion or wear.

- If your primary focus is low-cost bulk coating of simple shapes: Traditional methods like dip-coating or spray-coating are almost always more cost-effective and sufficient for the task.

By understanding its principles, you can leverage polymer CVD to achieve surface properties and device performance that are simply unattainable by other means.

Summary Table:

| Feature | Advantage |

|---|---|

| Process | Gas-phase, bottom-up assembly |

| Uniformity | Perfectly conformal on complex shapes |

| Purity | Solvent-free, high-purity films |

| Thickness Control | Nanometer-level precision |

| Adhesion | Strong covalent bonds for durability |

| Substrate Versatility | Works on metals, ceramics, glass, polymers |

Need a high-performance coating for your lab's most demanding applications?

KINTEK specializes in advanced lab equipment and consumables, including solutions for precision coating technologies like CVD. Whether you're developing medical implants, micro-electronics, or MEMS devices, our expertise can help you achieve ultra-pure, durable, and conformal polymer films. Contact us today to discuss how we can support your laboratory's innovation and efficiency with tailored solutions.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- CVD Diamond Domes for Industrial and Scientific Applications

People Also Ask

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition