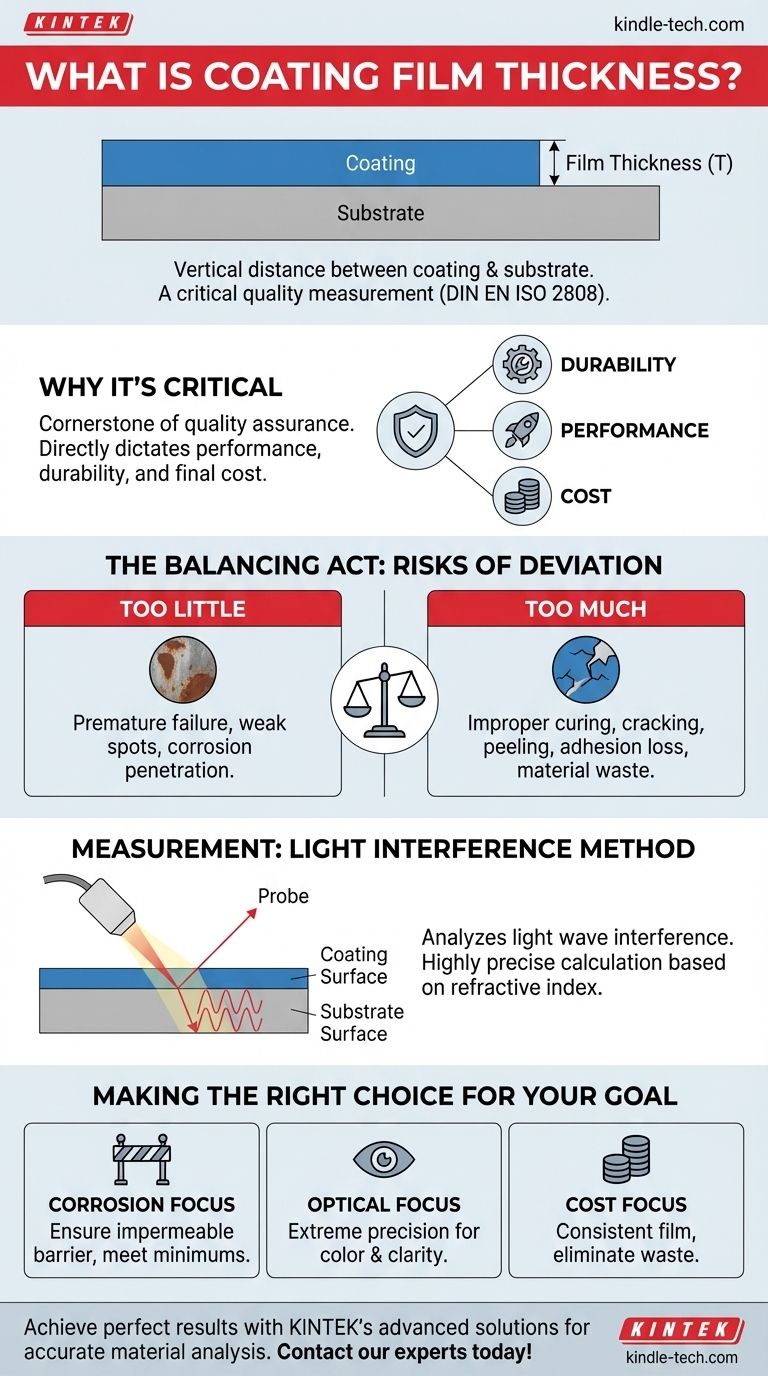

At its core, coating film thickness is the precise vertical distance between the surface of the coating and the surface of the object it is applied to, known as the substrate. As defined by the standard DIN EN ISO 2808, this is not just a physical dimension but a formal measurement result, obtained through a standardized and carefully applied method.

Film thickness is the single most critical measurement for a coating. It directly dictates the coating's performance, durability, and final cost, making its precise control a cornerstone of quality assurance.

Why Film Thickness is a Critical Quality Parameter

A coating is applied to a substrate to impart specific properties, such as corrosion resistance, wear protection, aesthetic appearance, or electrical insulation. The effectiveness of these properties is almost always directly proportional to the thickness of the applied film.

The Link Between Thickness and Performance

Too little coating can lead to premature failure. For example, a corrosion-resistant paint that is too thin will have weak spots where moisture and oxygen can penetrate, causing the substrate to rust despite the coating.

The Impact on Durability and Longevity

Conversely, too much coating can be just as detrimental. An overly thick layer may cure improperly, leading to cracking, peeling, or a lack of adhesion. This compromises the integrity of the finish and shortens the product's lifespan.

The Economic Consequences

Material costs are a significant factor in any coating process. Applying a film that is thicker than specified is a direct waste of material and money. Consistent and accurate thickness control ensures resources are used efficiently.

How Film Thickness is Measured

Various methods exist to measure film thickness, chosen based on the coating, the substrate, and the required precision. For thin, transparent, or semi-transparent films, optical methods are common.

The Principle of Light Interference

One advanced method analyzes the interference pattern of light. When light strikes the coated surface, some reflects off the top of the coating, and some passes through to reflect off the substrate underneath.

These two reflected light waves interfere with each other. By analyzing the resulting pattern of peaks and valleys, instruments can calculate the film's thickness with incredible precision.

The Role of Material Properties

This calculation is not universal; it depends on the refractive index of the coating material. The refractive index describes how fast light travels through a substance. Therefore, the measurement device must be calibrated for the specific material being measured to ensure accuracy.

Understanding the Trade-offs

Achieving the target film thickness is a balancing act. Deviating in either direction introduces significant risk.

The Dangers of an Insufficient Film

A film that is too thin is the most common cause of coating failure. It fails to provide the necessary barrier against environmental factors, leading to insufficient protection, poor color coverage, and a failure to meet technical specifications.

The Problems with an Excessive Film

Applying too much coating can lead to a host of issues, including extended drying times, sagging or running, and brittleness. This not only wastes material but can create a defective final product that must be reworked or scrapped.

Making the Right Choice for Your Goal

Controlling film thickness is about aligning the physical measurement with the intended outcome of the coating.

- If your primary focus is corrosion protection: Your priority is ensuring the film meets or slightly exceeds the minimum thickness required to create an impermeable barrier.

- If your primary focus is optical performance: You need extreme precision and uniformity, as even tiny variations in thickness can alter how light behaves, affecting color and clarity.

- If your primary focus is cost management: Your goal is to apply a consistent film that meets the minimum specification without over-application, eliminating material waste.

Ultimately, mastering the measurement and control of film thickness is fundamental to producing a reliable, effective, and cost-efficient product.

Summary Table:

| Aspect | Impact of Incorrect Film Thickness |

|---|---|

| Performance | Too thin: Premature failure (e.g., corrosion). Too thick: Improper curing, cracking. |

| Durability | Too thin: Weak barrier protection. Too thick: Peeling, adhesion loss. |

| Cost | Too thick: Direct material waste. Inconsistent: Rework and scrap costs. |

| Measurement | Precise methods like light interference analysis are required for accuracy. |

Achieve perfect coating results with precise thickness control.

Inconsistent film thickness leads to product failure and wasted resources. KINTEK specializes in providing laboratory equipment and consumables for accurate material analysis, including advanced solutions for coating measurement. Ensure your coatings meet specifications for performance, durability, and cost-efficiency.

Let us help you optimize your process. Contact our experts today to discuss your specific lab needs!

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Custom PTFE Teflon Parts Manufacturer for Three-Necked Round Bottom Flask

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

People Also Ask

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?

- Why is a laboratory precision hot press necessary for processing high-performance composite solid-state electrolyte membranes?

- Why is a laboratory hot press required for Oxygen Depolarized Cathodes? Ensure Precision Molding and Conductivity.

- What are the advantages of using a hot press for Li7P2S8I0.5Cl0.5? Boost Conductivity with Precision Densification

- What role does a hot press play in treating the CAL-GPE interface? Optimize Performance for Flexible Lithium Batteries