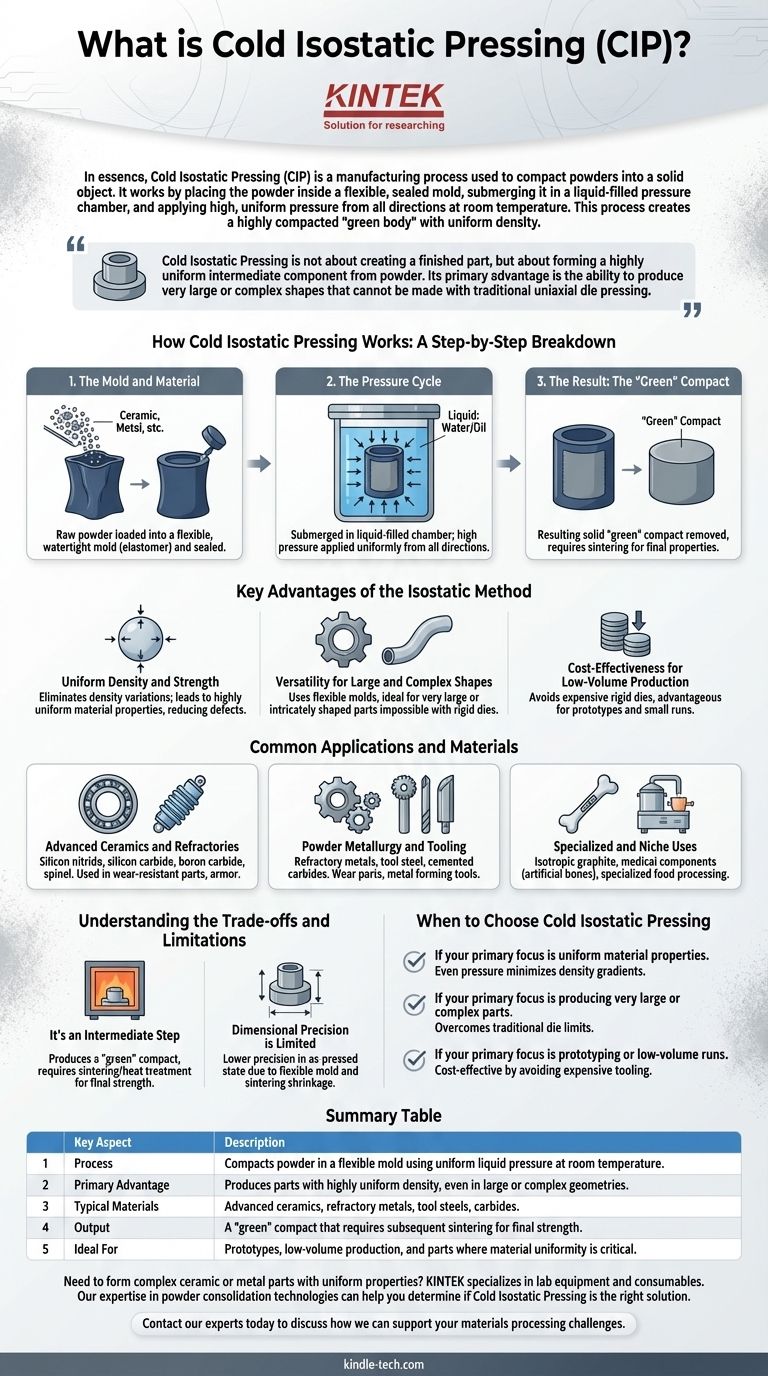

In essence, Cold Isostatic Pressing (CIP) is a manufacturing process used to compact powders into a solid object. It works by placing the powder inside a flexible, sealed mold, submerging it in a liquid-filled pressure chamber, and applying high, uniform pressure from all directions at room temperature. This process creates a highly compacted "green body" with uniform density.

Cold Isostatic Pressing is not about creating a finished part, but about forming a highly uniform intermediate component from powder. Its primary advantage is the ability to produce very large or complex shapes that cannot be made with traditional uniaxial die pressing.

How Cold Isostatic Pressing Works: A Step-by-Step Breakdown

The elegance of CIP lies in its simple but powerful principle: applying pressure equally from all directions. This is what the term isostatic means.

The Mold and Material

First, the raw powder—be it ceramic, metal, or another material—is loaded into a flexible, watertight mold, typically made of an elastomer like rubber or urethane. This mold is then sealed to protect the powder from the pressurizing liquid.

The Pressure Cycle

The sealed mold is placed inside a pressure vessel filled with a liquid, such as water or oil. A pump then increases the pressure of this liquid, which is transmitted uniformly to all surfaces of the flexible mold. This even pressure compacts the powder particles together, forcing out air and creating mechanical bonds.

The Result: The "Green" Compact

After reaching the target pressure, the system is depressurized. The resulting solid part, known as a "green" compact, is removed from the mold. This compact has sufficient strength for handling but must undergo a subsequent process, typically sintering (a high-temperature treatment), to achieve its final strength and material properties.

Key Advantages of the Isostatic Method

CIP is chosen over other powder compaction methods for several distinct advantages that solve specific manufacturing challenges.

Uniform Density and Strength

Because pressure is applied equally from all sides, CIP eliminates the density variations common in uniaxial (top-down) pressing. This results in a component with highly uniform density and strength, reducing internal stresses and the risk of defects.

Versatility for Large and Complex Shapes

Traditional die pressing is limited by the size and geometric complexity of the rigid die. CIP overcomes this by using a flexible mold, making it ideal for producing parts that are very large or have intricate shapes, which would be difficult or impossible to press otherwise.

Cost-Effectiveness for Low-Volume Production

Creating the hardened steel dies for uniaxial pressing is expensive. CIP is highly advantageous when the high initial cost of pressing dies cannot be justified, such as for prototypes, small production runs, or one-of-a-kind components.

Common Applications and Materials

CIP is a versatile technology used across a wide range of industries and materials where high performance and material integrity are critical.

Advanced Ceramics and Refractories

The process is widely used for consolidating high-performance ceramic powders. This includes materials like silicon nitride, silicon carbide, boron carbide, and spinel, which are used in wear-resistant components, armor, and electrical insulators.

Powder Metallurgy and Tooling

In powder metallurgy, CIP is used to form parts from refractory metals, tool steel, and cemented carbides. Common applications include wear parts and metal forming tools that benefit from uniform density and improved mechanical properties.

Specialized and Niche Uses

The applications extend beyond traditional engineering. CIP is also used to form isotropic graphite, medical components like artificial bones, and even in specialized food processing to compact powders without heat.

Understanding the Trade-offs and Limitations

While powerful, CIP is not a universal solution. Understanding its limitations is key to using it effectively.

It's an Intermediate Step

A key point to remember is that CIP produces a "green" compact, not a finished product. This part lacks the final hardness and strength required for its end-use application. It is almost always a preparatory step for a sintering or heat treatment process.

Dimensional Precision is Limited

The flexible nature of the mold and the shrinkage that occurs during sintering mean that CIP does not offer high dimensional precision in the as-pressed state. Final dimensions are typically achieved through post-sintering machining or by carefully accounting for predictable shrinkage.

When to Choose Cold Isostatic Pressing

Deciding if CIP is the right choice depends entirely on your project's goals and constraints.

- If your primary focus is uniform material properties: CIP is an excellent choice, as its even pressure minimizes density gradients and weak spots.

- If your primary focus is producing very large or complex parts: CIP is a leading solution because it overcomes the physical size and geometric limitations of traditional die presses.

- If your primary focus is prototyping or low-volume runs: CIP is highly cost-effective by avoiding the significant expense and lead time associated with manufacturing rigid tooling.

By understanding its principles, you can leverage Cold Isostatic Pressing to create high-integrity components that are otherwise unachievable.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Compacts powder in a flexible mold using uniform liquid pressure at room temperature. |

| Primary Advantage | Produces parts with highly uniform density, even in large or complex geometries. |

| Typical Materials | Advanced ceramics (e.g., silicon nitride), refractory metals, tool steels, carbides. |

| Output | A "green" compact that requires subsequent sintering for final strength. |

| Ideal For | Prototypes, low-volume production, and parts where material uniformity is critical. |

Need to form complex ceramic or metal parts with uniform properties?

KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and R&D facilities. Our expertise in powder consolidation technologies can help you determine if Cold Isostatic Pressing is the right solution for your project's requirements for uniformity, complex shapes, or cost-effective prototyping.

Contact our experts today to discuss how we can support your materials processing challenges.

Visual Guide

Related Products

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What is the meaning of isostatic pressing? Achieve Uniform Density in Complex Parts

- What is cold sintering? A Low-Energy Path to Novel Composite Materials

- What is the pressure for cold isostatic pressing? Achieve Superior Density and Uniformity

- What are the disadvantages of isostatic pressing? Weighing Speed, Cost, and Precision

- How much does an isostatic press cost? A Guide to Lab vs. Industrial Pricing

- What is the purpose of stainless steel cans in the HIP treatment? Achieve Full Densification of AlFeTiCrZnCu Alloys

- What is the pressure of isostatic fluid? Achieve Perfectly Uniform Density and Complex Shapes

- What are the different types of cold isostatic pressing? Wet-Bag vs. Dry-Bag for Your Production Needs