Controlled atmosphere heat treatment is a highly precise thermal process where the gaseous environment surrounding a metal part is strictly managed during heating and cooling. Unlike heating in open air, this method uses a specific gas mixture to prevent unwanted chemical reactions like oxidation and to deliberately introduce elements that enhance the material's surface properties.

The crucial shift in thinking is this: controlled atmosphere heat treatment moves beyond simply changing a metal's temperature. It is about fundamentally engineering the chemical reactions on the material's surface to achieve superior, consistent, and reliable results.

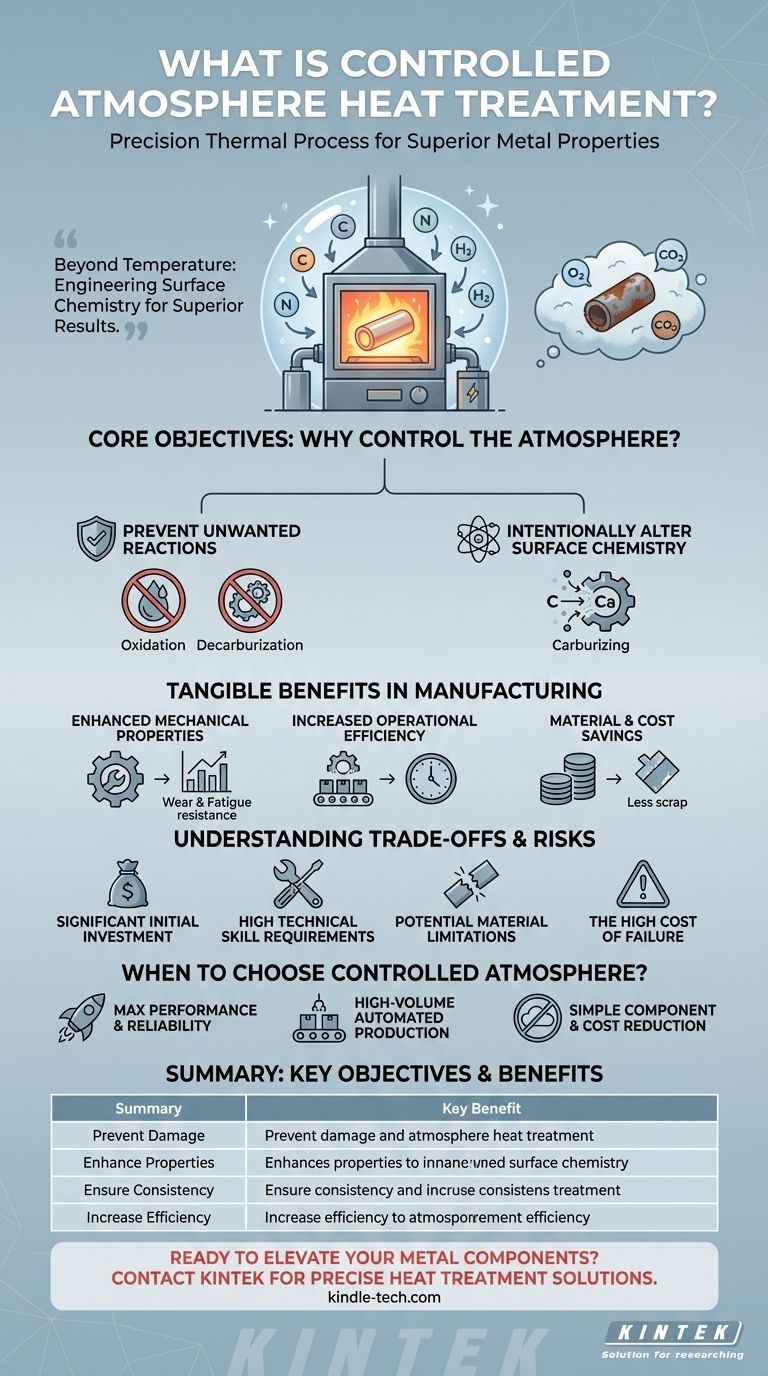

Why Control the Atmosphere? The Core Objectives

The decision to invest in controlled atmosphere technology stems from a need for precision that open-air heating cannot provide. The primary goals are to protect the material and, in many cases, to actively improve it.

To Prevent Unwanted Surface Reactions

When steel is heated in the presence of air, two damaging reactions occur. A controlled atmosphere is designed to stop them.

The first is oxidation, or scaling, which is essentially advanced rust that forms at high temperatures. This damages the surface finish and results in material loss.

The second is decarburization, a process where carbon leaches out of the steel's surface. This softens the surface layer, reducing the part's hardness and wear resistance.

To Intentionally Alter Surface Chemistry

Beyond prevention, this process is used to add elements to a part's surface. This is known as chemical heat treatment.

A common example is carburizing, where a carbon-rich atmosphere (using gases like natural gas) forces carbon atoms to diffuse into the surface of a low-carbon steel part. This creates a part with a hard, wear-resistant surface and a tough, ductile core.

To Ensure Consistent, High-Quality Results

By eliminating the variables of open air, a controlled atmosphere ensures that every part in a batch receives the exact same treatment. This leads to minimal part deformation, higher qualification rates, and predictable mechanical properties.

The Tangible Benefits in Manufacturing

Implementing this technology translates directly to measurable improvements in both product quality and operational efficiency.

Enhanced Mechanical Properties

By precisely controlling the carbon content on the surface, you can dramatically improve key characteristics. This includes superior wear resistance and fatigue strength, which are critical for components like gears and bearings.

Increased Operational Efficiency

Controlled atmosphere furnaces are often integrated into automated production lines. This setup reduces manual labor, shortens production cycle times, and saves significant manpower.

Material and Cost Savings

The process reduces or eliminates metal loss from oxidation and burning. It also allows manufacturers to use less expensive, low-carbon steel and then engineer a high-performance surface onto it, simplifying processing for complex or high-hardness parts.

Understanding the Trade-offs and Risks

While powerful, controlled atmosphere technology is not a universal solution. It requires a clear understanding of its demands and potential downsides.

Significant Initial Investment

The equipment required—including the furnace, gas generators, and monitoring systems—is considerably more complex and expensive than traditional open-air furnaces.

High Technical Skill Requirements

Operating and maintaining this equipment demands a higher level of technical expertise. Improper management of the gas composition can ruin parts or create safety hazards.

Potential Material Limitations

Certain materials can be negatively affected. For example, some steels are susceptible to hydrogen embrittlement when treated in an atmosphere with a high hydrogen content, making them brittle and prone to failure.

The High Cost of Failure

An improperly controlled atmosphere can do more than just fail to protect a part; it can actively damage it. This leads to rejected batches, wasted time, and significant financial loss. More critically, it can damage the furnace itself or, in the worst cases, injure employees.

When is Controlled Atmosphere the Right Choice?

Choosing this process depends entirely on your specific goals for the component and your manufacturing environment.

- If your primary focus is maximum performance and reliability: Controlled atmosphere is essential for creating parts with superior wear resistance and fatigue strength, such as in gearbox or aerospace applications.

- If your primary focus is high-volume, automated production: The process integrates seamlessly into automated lines, reducing labor costs and ensuring repeatable quality across thousands of parts.

- If your primary focus is cost reduction on a simple component: A simpler, open-air heat treatment may be more economical if precise surface chemistry and finish are not critical requirements.

Ultimately, adopting controlled atmosphere heat treatment is a strategic decision to trade higher initial complexity for unparalleled control, quality, and long-term efficiency.

Summary Table:

| Objective | Key Benefit |

|---|---|

| Prevent Damage | Eliminates surface oxidation (scaling) and decarburization |

| Enhance Properties | Improves surface hardness, wear resistance, and fatigue strength |

| Ensure Consistency | Provides repeatable, high-quality results for every part in a batch |

| Increase Efficiency | Reduces material loss and integrates into automated production lines |

Ready to elevate your metal components with precise, reliable heat treatment?

KINTEK specializes in advanced lab and production equipment, including solutions for controlled atmosphere processes. Our expertise helps manufacturers achieve superior part performance, consistent quality, and long-term operational efficiency.

Contact our experts today to discuss how we can support your specific laboratory and production needs.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- Can nitrogen be used for brazing? Key Conditions and Applications Explained

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes

- What gases are used in inert atmospheres? Choose the Right Gas for Non-Reactive Environments