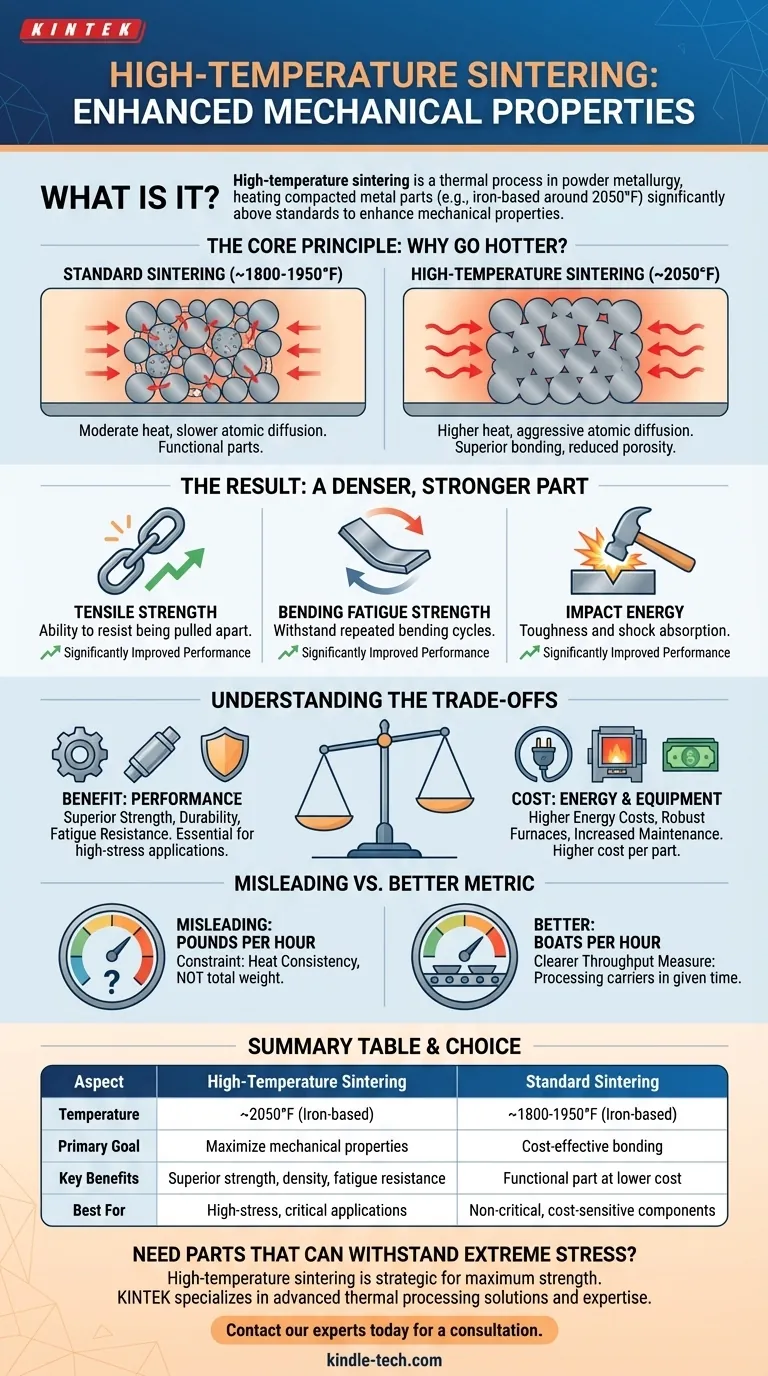

In essence, high-temperature sintering is a thermal process used in powder metallurgy where compacted metal parts are heated to temperatures significantly above conventional standards. For iron-based components, this means operating around 2050°F, approximately 100-250°F higher than normal. The primary goal is not just to fuse the metal particles but to fundamentally enhance the final part's mechanical properties.

While standard sintering creates a functional part, high-temperature sintering is a strategic investment. It trades higher energy costs for superior material strength, density, and fatigue resistance, enabling components to perform in more demanding applications.

The Core Principle: Why Go Hotter?

Sintering works by using heat to encourage atoms to diffuse across the boundaries of individual metal powder particles, fusing them into a solid, coherent mass. Raising the temperature accelerates this process dramatically.

The Impact of Higher Temperatures

Increasing the heat energy in the furnace promotes more aggressive atomic diffusion. This allows the metal particles to bond more completely and reduces the size and number of internal voids, or pores, that are a natural byproduct of the powder metallurgy process.

The Result: A Denser, Stronger Part

This enhanced atomic bonding and reduced porosity directly translate to superior mechanical properties. A part that undergoes high-temperature sintering will exhibit significantly better performance characteristics compared to its conventionally sintered counterpart.

Key Performance Gains

Specifically, you can expect improvements in:

- Tensile Strength: The ability to resist being pulled apart.

- Bending Fatigue Strength: The capacity to withstand repeated bending cycles without failing.

- Impact Energy: The toughness of the material and its ability to absorb a sudden shock.

Understanding the Trade-offs

Choosing this process requires a clear understanding of what you gain and what you sacrifice. It is a decision driven entirely by the final application's performance requirements.

The Primary Benefit: Unlocking Performance

The reason to select high-temperature sintering is straightforward: to create parts that are stronger, tougher, and more durable. This makes it essential for high-stress applications like automotive transmission gears or other components where failure is not an option.

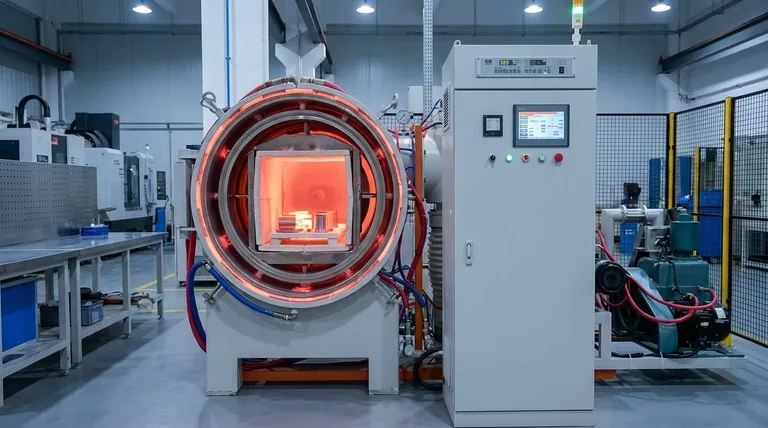

The Inescapable Cost: Energy and Equipment

The primary drawback is cost. Maintaining temperatures around 2050°F requires substantially more energy. It also necessitates more robust and specialized furnaces, which increases capital and maintenance expenses, leading to a higher cost per part.

The Misleading Metric: "Pounds per Hour"

When evaluating production output, you will often hear furnaces discussed in terms of "pounds per hour." This can be a misleading metric. The furnace's true constraint is its ability to deliver consistent heat to the parts, not the total weight it can hold.

A Better Measure: "Boats per Hour"

A more meaningful indicator of throughput is "boats per hour." A "boat" is a tray or carrier that moves parts through the furnace. This metric measures how many of these carriers a furnace can process in a given time, providing a much clearer picture of its capacity regardless of part size, shape, or density.

Making the Right Choice for Your Application

The decision to use high-temperature sintering should be based on a clear cost-benefit analysis for your specific component.

- If your primary focus is cost-effectiveness for non-critical components: Standard sintering is often the more economical and perfectly sufficient choice.

- If your primary focus is maximum strength, fatigue resistance, and durability: The investment in high-temperature sintering is necessary to meet demanding performance requirements.

- If you are evaluating manufacturing partners or equipment: Ask about throughput in "boats per hour" to get a more accurate assessment of production capacity.

Ultimately, choosing high-temperature sintering is a deliberate engineering decision to prioritize ultimate part performance over initial production cost.

Summary Table:

| Aspect | High-Temperature Sintering | Standard Sintering |

|---|---|---|

| Temperature | ~2050°F (Iron-based) | ~1800-1950°F (Iron-based) |

| Primary Goal | Maximize mechanical properties | Cost-effective bonding |

| Key Benefits | Superior strength, density, fatigue resistance | Functional part at lower cost |

| Best For | High-stress, critical applications (e.g., transmission gears) | Non-critical, cost-sensitive components |

Need parts that can withstand extreme stress?

High-temperature sintering is a strategic process for achieving maximum strength, density, and fatigue resistance in your metal components. If your application demands superior performance, the investment is essential.

KINTEK specializes in providing the advanced thermal processing solutions and expertise needed for high-performance sintering. We supply robust laboratory furnaces and consumables designed for demanding processes, helping you create durable, reliable parts.

Let's discuss your project requirements and how we can help you achieve optimal results.

Contact our experts today for a consultation.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Does temperature affect compression of gases? Why Hot Gases Resist Compression More

- What is magnetron sputtering used for? Create High-Performance Thin Films for Your Industry

- What are the advantages of handheld XRF? Achieve Instant, On-Site Elemental Analysis

- What is the operating pressure for a filter press? Master the Pressure Curve for Optimal Dewatering

- What is the process of vim var melting? Master Vim Variable Scopes for Bug-Free Scripting

- Is a carbon brush a good conductor of electricity? The Surprising Engineering Choice

- What affects sputtering yield? Master the Physics for Maximum Deposition Efficiency

- How are heat treatment furnaces classified? A Guide to Matching Furnace Type to Your Process Goal