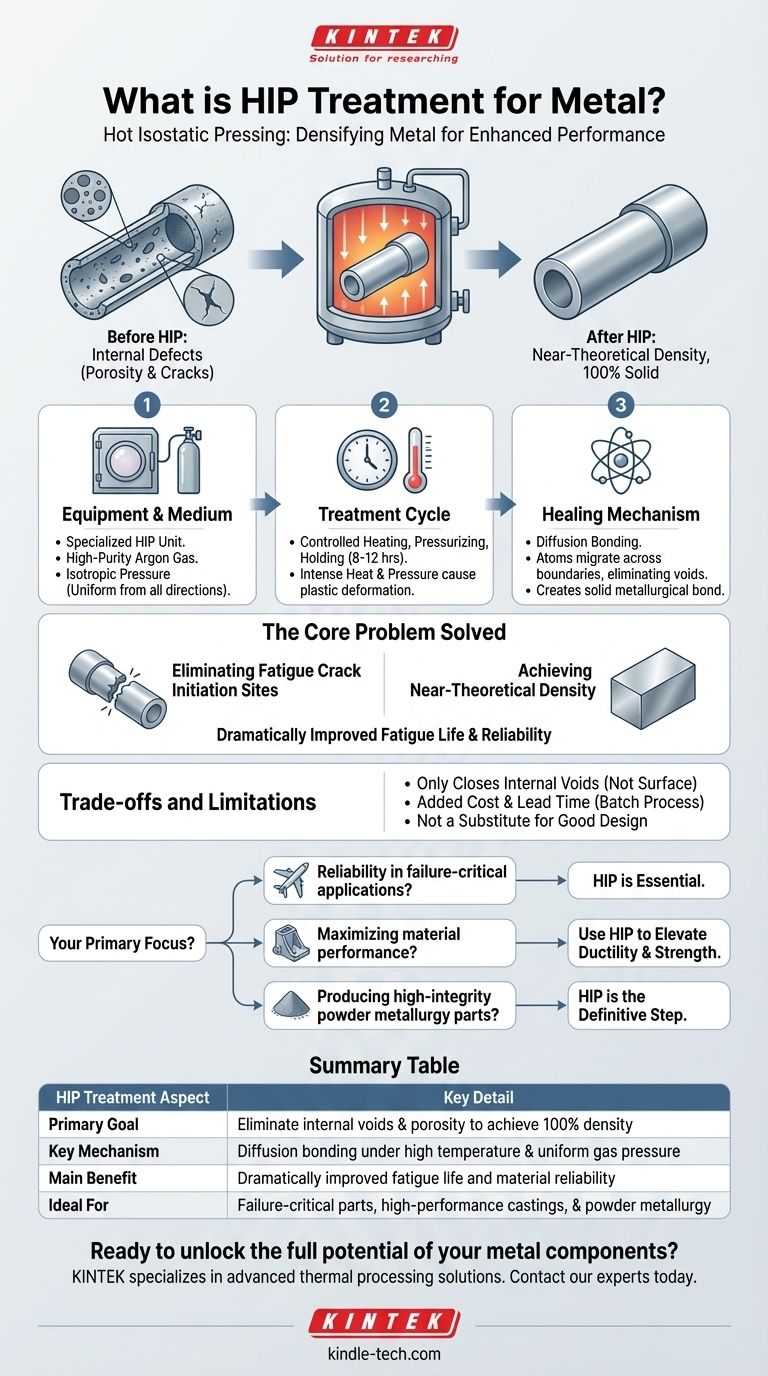

At its core, Hot Isostatic Pressing (HIP) is a materials treatment process that subjects a component to both elevated temperature and high, uniform gas pressure. This combination is applied for a specific duration to collapse and diffusion-bond internal voids, cracks, or porosity within a metal part. The result is a denser, stronger, and more reliable material with properties that can rival those of wrought alloys.

The fundamental purpose of HIP is to heal internal defects. By applying uniform (isostatic) pressure at high temperatures, it physically eliminates microporosity, turning a potentially flawed component into a fully dense, high-performance part with dramatically improved fatigue life.

How the HIP Process Works

The HIP process is methodical and takes place inside a specialized piece of equipment that combines a high-temperature furnace with a high-pressure containment vessel.

### The Equipment and Medium

Parts are loaded into the HIP unit's chamber. This chamber is then sealed, heated, and filled with a high-purity inert gas, most commonly argon.

This gas acts as the pressure medium, ensuring that pressure is applied isotropically—that is, uniformly from all directions.

### The Treatment Cycle

The cycle involves three main phases: pressurization and heating, holding (or "soaking"), and cooling. The temperature, pressure, and duration are precisely controlled based on the specific alloy and desired outcome.

A typical HIP cycle can last from 8 to 12 hours. The intense heat softens the material, allowing the high gas pressure to cause plastic deformation and creep, which forces the internal surfaces of any voids together.

### The Healing Mechanism: Diffusion Bonding

Once the void surfaces are in intimate contact, diffusion bonding occurs. At the atomic level, atoms migrate across the boundary, effectively eliminating the former void and creating a solid, homogeneous metallurgical bond.

This completely removes defects like shrinkage porosity from castings or voids between powder particles in powder metallurgy.

The Core Problem HIP Solves: Internal Defects

Many manufacturing processes, especially metal casting and powder metallurgy, can leave behind microscopic internal voids. These defects are the primary cause of premature component failure.

### Eliminating Fatigue Crack Initiation Sites

Microporosity and internal cracks act as stress concentrators. When a part is under cyclic loading, these tiny defects become the initiation sites for fatigue cracks, which can grow and lead to catastrophic failure.

By eliminating these internal voids, HIP removes the root cause of many fatigue failures.

### Achieving Near-Theoretical Density

The ultimate goal of HIP is to produce a component with 100% of its theoretical maximum density. This densification is what drives the significant improvement in the material's mechanical properties.

### Improving Product Consistency

The presence and size of internal defects can vary significantly from one part to another, leading to inconsistent performance. HIP removes this variable, resulting in parts with far less variation in their mechanical properties and predictable service life.

Understanding the Trade-offs and Limitations

While powerful, HIP is not a universal solution. It is a specific tool for solving a specific problem.

### Only Internal Voids are Closed

The fundamental requirement for HIP to work is that the pressure can't leak out. Therefore, the process can only close voids that are not connected to the surface of the part. It is not a surface treatment.

### Added Cost and Lead Time

HIP is a batch process performed in specialized equipment, which adds both cost and time to the manufacturing cycle. This investment must be justified by the need for enhanced reliability or performance.

### Not a Substitute for Good Design

HIP enhances the properties of a well-designed part; it cannot fix a fundamentally flawed design. It improves the material's integrity but does not change its shape or geometry.

Making the Right Choice for Your Goal

Specifying HIP treatment is a strategic decision based on the performance and reliability requirements of the final component.

- If your primary focus is reliability in failure-critical applications: HIP is essential for removing the internal defects that could lead to fatigue failure in components like aerospace engine parts or medical implants.

- If your primary focus is maximizing material performance: Use HIP to elevate the ductility and fatigue strength of a casting to a level comparable to a more expensive wrought or forged part.

- If your primary focus is producing high-integrity powder metallurgy parts: HIP is the definitive step to transform compacted metal powder into a fully dense, high-performance solid component.

Ultimately, Hot Isostatic Pressing is a powerful tool for unlocking the full potential of a metallic material.

Summary Table:

| HIP Treatment Aspect | Key Detail |

|---|---|

| Primary Goal | Eliminate internal voids & porosity to achieve 100% density |

| Key Mechanism | Diffusion bonding under high temperature & uniform gas pressure |

| Main Benefit | Dramatically improved fatigue life and material reliability |

| Ideal For | Failure-critical parts (aerospace, medical), high-performance castings, & powder metallurgy |

Ready to unlock the full potential of your metal components? KINTEK specializes in advanced thermal processing solutions. Our expertise in lab equipment and consumables can help you determine if HIP treatment is the right choice to enhance the strength, reliability, and performance of your critical parts. Contact our experts today to discuss your specific application and material goals.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the pressure of hot isostatic pressing? Unlock Full Material Density with High-Pressure HIP

- What are the parameters of HIP process? Master Temperature, Pressure, and Time for Superior Densification

- What is the meaning of Hot Isostatic Pressing? Achieve 100% Density and Superior Material Integrity

- What are the conditions for hot isostatic pressing? Unlock Maximum Material Density

- What is the purpose of using a high-vacuum diffusion pump system for pre-treating powder capsules in HIP? Avoid PPBs

- Why is Hot Isostatic Pressing (HIP) Required for Additive Inconel 718? Achieve 100% Theoretical Density

- What is the hot isostatic process? Achieve Perfect Material Density for Critical Components

- How does Hot Isostatic Pressing reduce porosity? Eliminate Internal Voids for Superior Material Density