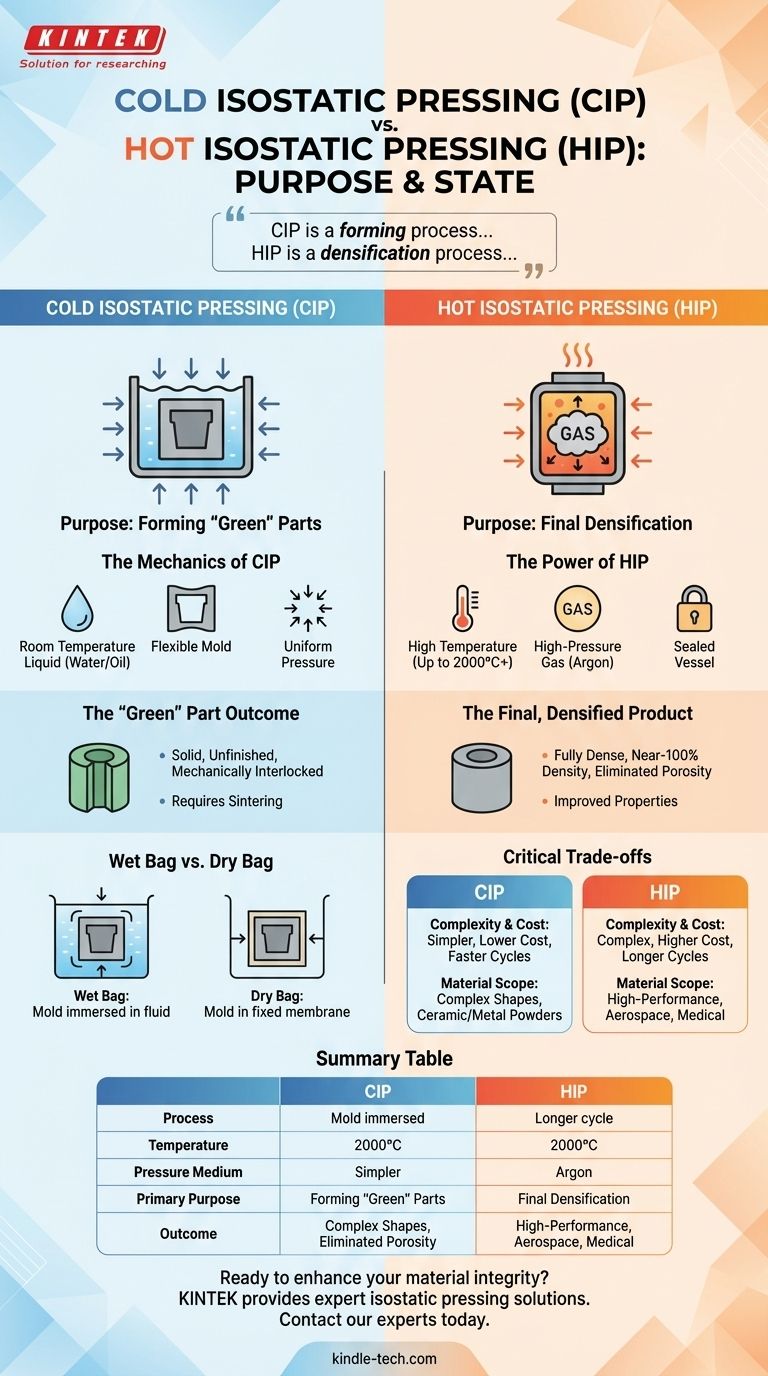

At its core, the difference is one of purpose and state. Cold Isostatic Pressing (CIP) uses liquid pressure at room temperature to compact powders into a solid, but unfinished, "green" part. In contrast, Hot Isostatic Pressing (HIP) uses high-pressure gas at extreme temperatures to fully densify materials, eliminate internal defects, and create a finished, high-performance component.

The crucial distinction is not just temperature, but the manufacturing stage. CIP is a forming process that creates a preliminary shape. HIP is a densification process that achieves the final material properties, often on parts that have already been formed.

The Mechanics of Cold Isostatic Pressing (CIP)

Cold Isostatic Pressing, sometimes called hydrostatic forming, is a foundational step for creating parts from powders. Its primary goal is to produce a uniformly dense pre-form for subsequent processing.

The Core Principle: Uniform Pressure

CIP leverages the fundamental property of liquids to transmit pressure equally in all directions.

This hydrostatic pressure is applied to a flexible mold containing the powder, ensuring the material compacts with exceptional uniformity from every angle.

The Process in Practice

The process is straightforward. A powder-filled, flexible mold is sealed and submerged in a pressure chamber filled with a liquid, typically water or oil.

An external pump pressurizes the liquid, compressing the mold and its contents. This cycle is often fast and occurs at or near room temperature.

The "Green" Part Outcome

The result of CIP is a "green" part. This component is solid and has enough strength to be handled and machined.

However, the powder particles are only mechanically interlocked. It must undergo a subsequent high-temperature process, like sintering, to metallurgically bond the particles and achieve its final strength.

Wet Bag vs. Dry Bag

There are two main methods of CIP. In wet bag pressing, the mold is directly immersed in the fluid for each cycle. In dry bag pressing, the mold is placed inside a permanent, flexible membrane built into the pressure vessel, allowing for faster automation and higher production volumes.

The Power of Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing is a thermal treatment process used to achieve a level of material integrity that is otherwise impossible. It is a finishing step designed to create parts with near-100% theoretical density.

The Core Principle: Heat and Force Combined

HIP subjects components to both elevated temperature and extremely high gas pressure inside a sealed vessel.

The high temperature reduces the material's strength, allowing the high isostatic pressure to close and weld shut any internal pores, voids, or micro-cracks. An inert gas, most commonly argon, is used as the pressure medium to prevent any reaction with the material.

The Process in Practice

Parts are loaded into the HIP vessel, which is then sealed and heated. As the temperature rises, the inert gas is pumped in, increasing the pressure up to 200 MPa or more.

Temperature, pressure, and time are precisely controlled to achieve full densification. The cycle finishes with a controlled cool-down and depressurization phase.

The Final, Densified Product

The output is a fully dense component with dramatically improved mechanical properties, including fatigue life and fracture toughness.

HIP is used to eliminate porosity in critical castings, consolidate powders into a final net shape, and even join dissimilar materials together with a perfect metallurgical bond.

Understanding the Critical Trade-offs

Choosing between these processes requires a clear understanding of their distinct roles, complexities, and costs.

Purpose: Forming vs. Finishing

The most significant difference is the manufacturing goal. CIP is a shaping step used to form a pre-form. HIP is a finishing step used to perfect a part's internal structure. Sometimes, a part may even undergo CIP to be formed and then, after sintering, undergo HIP for final densification.

Process Complexity and Cost

CIP systems operate at room temperature with liquids, making the equipment relatively simpler and less expensive. The cycle times are often shorter.

HIP requires a highly specialized vessel that can safely manage extreme temperatures and gas pressures simultaneously. This makes the equipment, and the process itself, significantly more complex and costly.

Material and Application Scope

CIP is ideal for creating complex shapes from ceramic or metal powders that require uniform density before they are fired or sintered.

HIP is reserved for high-performance applications where material failure is not an option, such as aerospace turbine blades, medical implants, and critical industrial components.

Making the Right Choice for Your Goal

Selecting the correct process is not a matter of which is "better," but which is appropriate for the specific task in your manufacturing workflow.

- If your primary focus is creating a complex, uniform 'green' part from powder before sintering: CIP is the correct and cost-effective choice.

- If your primary focus is eliminating internal porosity in a metal casting to improve its mechanical properties: HIP is the necessary densification treatment.

- If your primary focus is consolidating metal or ceramic powder directly into a fully dense, high-performance final part: HIP is the process that can combine forming and densification into a single, powerful step.

By understanding the distinction between a forming process and a densification process, you can select the precise technology to achieve optimal material integrity.

Summary Table:

| Process | Temperature | Pressure Medium | Primary Purpose | Outcome |

|---|---|---|---|---|

| Cold Isostatic Pressing (CIP) | Room Temperature | Liquid (Water/Oil) | Forming "Green" Parts | Uniform powder compaction for sintering |

| Hot Isostatic Pressing (HIP) | High Temperature (Up to 2000°C+) | Gas (Argon) | Final Densification | Near-100% density, defect elimination |

Ready to enhance your material integrity? Whether you need to form complex powder pre-forms with CIP or achieve full densification with HIP, KINTEK's expertise in lab equipment and consumables can help you select the perfect isostatic pressing solution for your laboratory or manufacturing needs. Contact our experts today to discuss how our specialized equipment can improve your component performance and reliability.

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is isostatic pressing in powder metallurgy? Unlock Superior Part Density and Complexity

- Why is cold working better than hot working? A Guide to Choosing the Right Metal Forming Process

- What are the applications of cold isostatic pressing? Achieve Uniform Density for Complex Parts

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction

- What is the cold isostatic pressing method? Achieve Uniform Density in Complex Parts