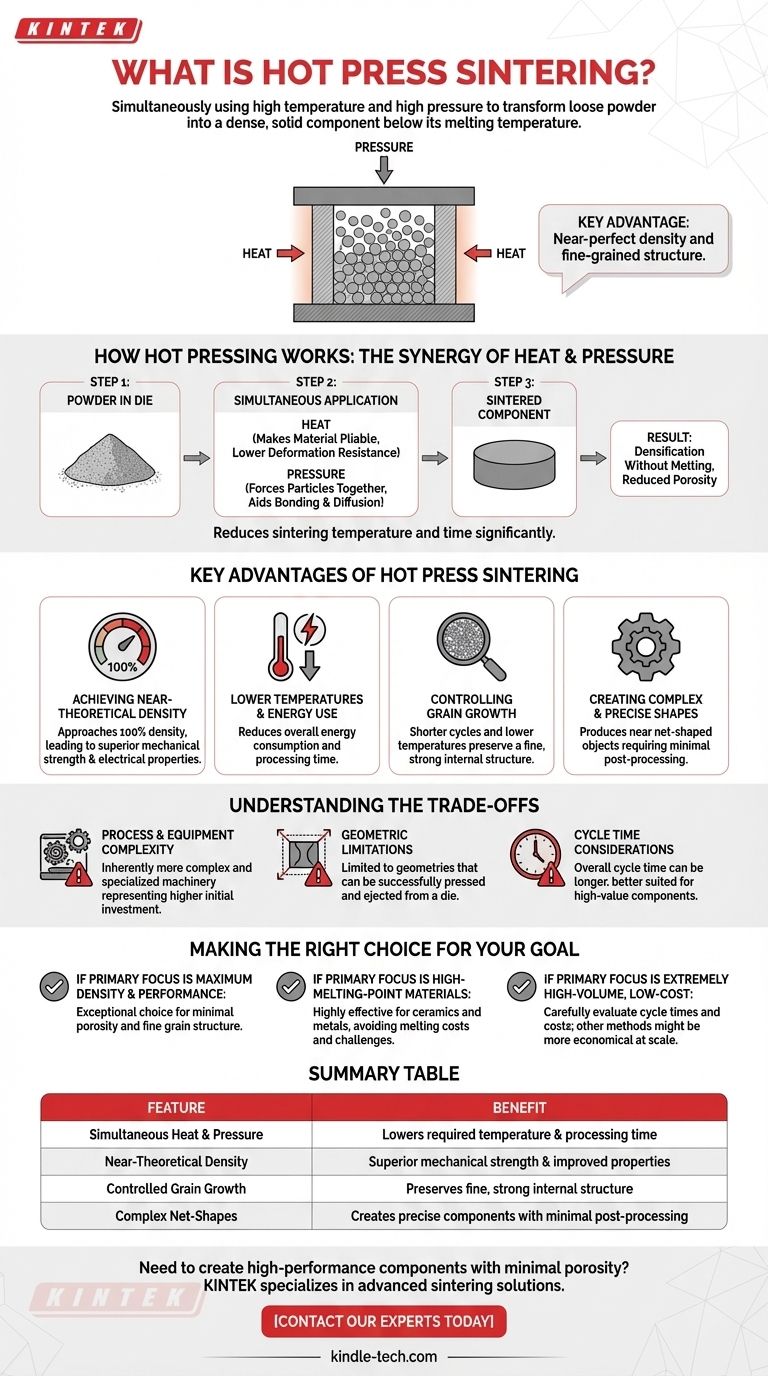

In essence, hot press sintering is a manufacturing process that uses high temperature and high pressure simultaneously to transform a loose powder into a dense, solid component. Unlike traditional melting, the material is heated to a point below its melting temperature, allowing the particles to fuse together under mechanical force. This dual action is the key to its effectiveness.

The central advantage of hot press sintering is its ability to produce materials with near-perfect density and a fine-grained internal structure. By applying heat and pressure at the same time, it lowers the required temperature and processing time, which in turn leads to superior final properties compared to many other methods.

How Hot Pressing Works: The Synergy of Heat and Pressure

To understand hot press sintering, it's crucial to see how its two core elements—heat and pressure—work together to achieve a result that neither could accomplish as effectively on its own.

The Fundamental Goal: Densification Without Melting

The basic principle of any sintering process is to reduce the porous spaces between individual particles of a powder. This compacts the material into a solid lump with significantly improved strength and other properties.

The Key Difference: Simultaneous Application

Traditional methods might involve "cold pressing" a powder into a shape and then heating it in a separate furnace step. Hot pressing integrates these into one operation.

The applied heat makes the powder material more pliable, almost like a thermoplastic. In this state, the material has a much lower deformation resistance.

Aiding Mass Transfer and Bonding

This thermoplastic state allows the simultaneously applied pressure to be far more effective. It physically forces the particles together, aiding the diffusion and bonding processes at the particle boundaries.

This synergy dramatically reduces the sintering temperature and time needed to achieve full density, often requiring only one-tenth of the pressure used in cold pressing.

The Key Advantages of Hot Press Sintering

The unique mechanism of hot pressing translates directly into a series of distinct benefits for the final product and the manufacturing process itself.

Achieving Near-Theoretical Density

The combination of heat and pressure is exceptionally efficient at eliminating porosity. This allows for the creation of sintered parts that approach 100% of their theoretical density.

This high density is directly linked to superior mechanical strength and improved electrical properties.

Lower Temperatures and Energy Use

Because pressure assists the densification process, the required temperatures are significantly lower than in pressureless sintering. This reduces overall energy consumption and processing time.

Controlling Grain Growth

A major challenge in metallurgy and ceramics is that high temperatures held for long periods can cause the internal grains of the material to grow larger. Large grains often lead to reduced strength and toughness.

Hot pressing's shorter cycles and lower temperatures effectively inhibit this grain growth, preserving a fine, strong internal structure.

Creating Complex and Precise Shapes

The process allows for the production of complex and accurately sized products. Because the part is formed and solidified in a single step within a die, it can create nearly net-shaped objects that require minimal post-processing.

Understanding the Trade-offs

While powerful, hot press sintering is not a universal solution. An objective assessment requires understanding its practical limitations.

Process and Equipment Complexity

The machinery required to safely apply high temperatures and significant mechanical pressure at the same time is inherently more complex and specialized than a standard furnace or a press alone. This can represent a notable initial investment.

Geometric Limitations

The process relies on a die to contain the powder and apply pressure. While capable of complex shapes, it is limited to geometries that can be successfully pressed and ejected from a mold. This is more restrictive than additive manufacturing methods like binder jetting.

Cycle Time Considerations

While the sintering phase is fast, the overall cycle time—including loading the powder, heating the die, pressing, cooling, and ejecting the part—can be longer than for some high-volume manufacturing methods. This often makes it better suited for high-value components rather than mass-produced parts.

Making the Right Choice for Your Goal

Selecting a manufacturing process depends entirely on your project's specific priorities.

- If your primary focus is maximum density and material performance: Hot press sintering is an exceptional choice for creating parts with minimal porosity and a fine grain structure, leading to superior strength.

- If your primary focus is working with high-melting-point metals or ceramics: This process is highly effective, as it avoids the extreme energy costs and technical challenges of trying to melt and cast these materials.

- If your primary focus is extremely high-volume, low-cost production: You should carefully evaluate the cycle times and equipment costs, as other methods like conventional powder metallurgy might be more economical at scale.

Ultimately, choosing hot press sintering is a strategic decision to prioritize final material quality and performance.

Summary Table:

| Feature | Benefit |

|---|---|

| Simultaneous Heat & Pressure | Lowers required temperature and processing time |

| Near-Theoretical Density | Superior mechanical strength and improved properties |

| Controlled Grain Growth | Preserves fine, strong internal structure |

| Complex Net-Shapes | Creates precise components with minimal post-processing |

Need to create high-performance components with minimal porosity?

KINTEK specializes in advanced lab equipment, including sintering solutions, to help you achieve superior material density and performance. Our expertise supports the precise needs of laboratories working with advanced ceramics, metals, and composites.

Contact our experts today to discuss how our solutions can enhance your R&D and manufacturing processes.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are the benefits of utilizing a Vacuum Hot Press (VHP) for Mg3Sb2? Maximize Thermoelectric Efficiency Today

- What is the purpose of maintaining a vacuum environment in hot press sintering WCp/Cu? Ensure High Density & Purity

- Why is a vacuum hot pressing furnace required for bulk amorphous Ni-Zr-Ti-Si alloys? Ensure High-Purity Densification

- What role does the hot pressing process play in the fabrication of TlBr crystals? Achieve High-Performance Densification

- What are the technical advantages of using vacuum hot pressing for Mg2Si? Achieve Dense Nanocrystalline Structures

- What are the advantages of using a vacuum hot press furnace for sintering CNT/Cu composites? Superior Density & Bonding

- What role does a Vacuum Hot Press (VHP) furnace play in the densification of austenitic stainless steel 316 composites?

- How does a vacuum hot pressing furnace (VHP) achieve high density and infrared transparency in ZnS? Master Ceramic Sintering