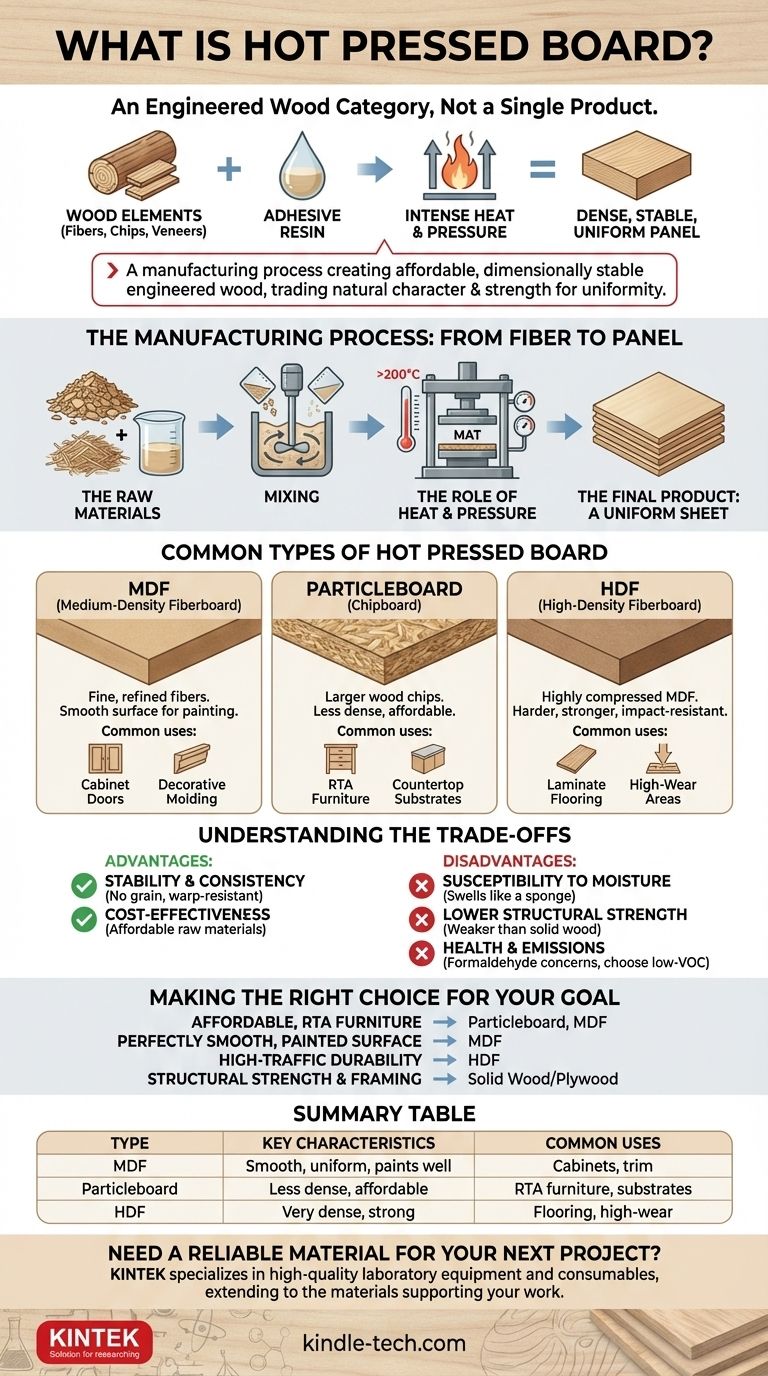

In essence, "hot pressed board" is not a single product but a broad category of engineered wood created by combining wood elements—like fibers, chips, or veneers—with an adhesive resin and fusing them together under intense heat and pressure. The most common examples you will encounter are Medium-Density Fiberboard (MDF), particleboard, and High-Density Fiberboard (HDF). This manufacturing process produces dense, stable, and uniform panels that are free from the natural defects of solid wood like knots and grain.

The term "hot pressed board" describes the manufacturing process used to create affordable and dimensionally stable engineered wood panels. The core trade-off is sacrificing the natural character and structural strength of solid wood for uniformity, workability, and lower cost.

The Manufacturing Process: From Fiber to Panel

Understanding how these boards are made is key to understanding their properties. The process transforms wood byproducts into a consistent and predictable building material.

The Raw Materials

Instead of using whole lumber, hot pressed boards are made from the residuals of the timber industry. This includes wood fibers, small chips, sawdust, or shavings. These raw materials are mixed with a synthetic resin, which acts as a powerful binder.

The Role of Heat and Pressure

This mixture is laid out in a large, flat "mat." This mat is then fed into a massive hydraulic press. The press applies immense pressure while simultaneously heating the mat to high temperatures, often over 200°C (400°F). The heat activates the resin, causing it to cure and permanently bond the wood particles together, while the pressure compacts them into a dense, solid sheet.

The Final Product: A Uniform Sheet

The result is a man-made panel that is exceptionally flat, stable, and consistent in density and thickness from edge to edge. Unlike solid wood, it has no grain direction, which means it won't warp, twist, or split due to changes in humidity.

Common Types of Hot Pressed Board

While they share a manufacturing principle, different types of hot pressed board have distinct characteristics and uses.

MDF (Medium-Density Fiberboard)

MDF is made from very fine, refined wood fibers. This results in an incredibly smooth, dense surface that is perfect for painting. It has no grain or voids, making it the go-to material for cabinet doors, decorative molding, and furniture requiring a flawless painted finish.

Particleboard (Chipboard)

Particleboard is made from larger wood chips and particles. It is less dense and less expensive than MDF. You will find it used extensively in ready-to-assemble furniture, kitchen countertops (as the core under a laminate), and as a general-purpose substrate where surface smoothness is less critical.

HDF (High-Density Fiberboard)

As the name suggests, HDF is MDF that has been compressed to an even greater density. This makes it much harder, stronger, and more resistant to impact and moisture. Its primary use is as the core material for high-quality laminate flooring.

Understanding the Trade-offs

Hot pressed boards are a feat of engineering, but they come with a clear set of advantages and disadvantages compared to solid wood.

Advantage: Stability and Consistency

Because they lack a natural grain structure, these boards are dimensionally stable. They expand and contract very little, making them ideal for large panels in furniture and cabinetry where warping would be a major issue.

Advantage: Cost-Effectiveness

Hot pressed boards are manufactured from wood byproducts and recycled materials. This makes them significantly more affordable than solid lumber of a comparable size.

Disadvantage: Susceptibility to Moisture

Unless specifically treated for moisture resistance, standard MDF and particleboard act like sponges. Water exposure causes them to swell, lose their structural integrity, and crumble. The damage is typically irreversible.

Disadvantage: Lower Structural Strength

While dense, these boards do not have the long-fiber strength of solid wood. They are weaker in load-bearing applications and do not hold screws as well, especially if screws are repeatedly inserted and removed.

Consideration: Health and Emissions

The resins used to bind the wood particles, particularly urea-formaldehyde (UF), can release formaldehyde gas over time, which is a Volatile Organic Compound (VOC). Regulations have tightened significantly, and many manufacturers now offer low-VOC or No-Added-Urea-Formaldehyde (NAUF) boards for sensitive applications.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on your project's budget, finish requirements, and structural demands.

- If your primary focus is affordable, ready-to-assemble furniture: Particleboard and MDF are the standard for a reason, offering excellent value and function for most household uses.

- If your primary focus is a perfectly smooth, painted surface: MDF is the superior choice for cabinetry, shelving, and trim due to its complete lack of wood grain.

- If your primary focus is high-traffic durability like flooring: HDF is the engineered material specifically designed for this level of strength and wear resistance.

- If your primary focus is structural strength for framing or heavy-duty projects: Solid wood or construction-grade plywood remains the more reliable and robust option.

Ultimately, understanding hot pressed board allows you to appreciate it as an engineered solution designed for specific modern needs.

Summary Table:

| Type | Key Characteristics | Common Uses |

|---|---|---|

| MDF | Smooth surface, uniform, paints well | Cabinets, painted furniture, trim |

| Particleboard | Less dense, very affordable | Ready-to-assemble furniture, countertop substrate |

| HDF | Very dense, strong, impact-resistant | Laminate flooring, high-wear applications |

Need a reliable material for your next project? Understanding the right type of engineered wood is key to achieving the perfect balance of cost, durability, and finish. At KINTEK, we specialize in providing high-quality laboratory equipment and consumables, and our expertise extends to the materials that support your work. Whether you're fabricating custom lab furniture or require stable substrates for specialized applications, we can help. Contact our experts today to discuss your specific needs and discover the right solutions for your laboratory.

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What is the role of a laboratory-grade heated hydraulic press in MEA fabrication? Optimize Fuel Cell Performance

- What causes hydraulic pressure spikes? Prevent System Damage from Hydraulic Shock

- How much force can a hydraulic press exert? Understanding its immense power and design limits.