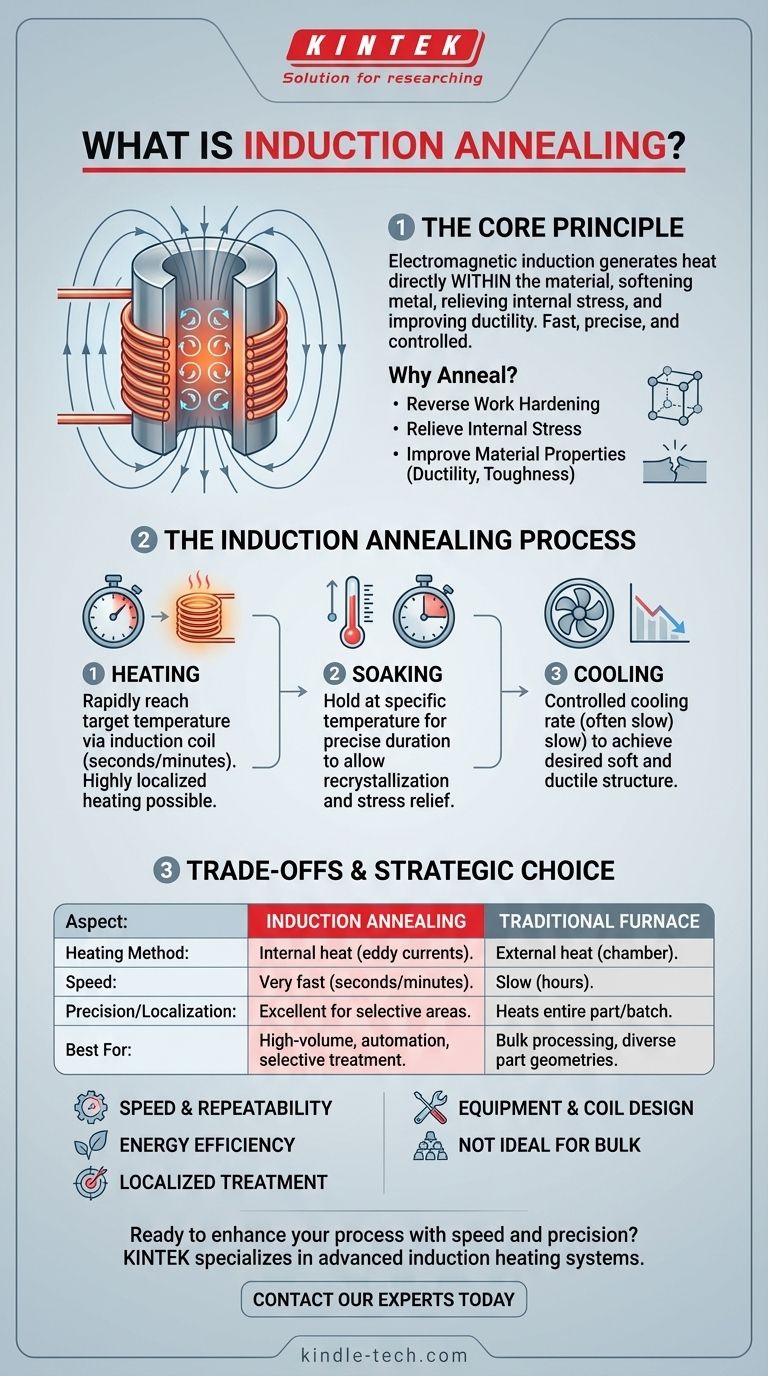

At its core, induction annealing is a highly controlled heat treatment process that uses electromagnetic induction to soften a metal, relieve its internal stresses, and improve its ductility. Unlike traditional furnace heating, which heats the entire component from the outside in, induction generates heat directly within the material itself, offering significant advantages in speed and precision.

The central purpose of any annealing process is to make a metal more workable. Induction annealing achieves this by using a clean, rapid, and highly targeted heating method, making it an ideal solution for modern, automated manufacturing where speed and repeatability are critical.

The Fundamental Goal: What is Annealing?

Annealing is not a single process but a category of heat treatments designed to alter a material's physical and sometimes chemical properties. The primary goal is to reverse the effects of processes that make the metal harder and more brittle.

Reversing Work Hardening

Processes like cold forming, drawing, or bending a metal cause its internal crystalline structure to deform and lock up. This effect, known as work hardening, makes the material stronger but also significantly less ductile and more prone to cracking if further work is attempted. Annealing reverses this by allowing the crystal structure to reform.

Relieving Internal Stress

Operations like welding, grinding, or heavy machining introduce significant internal stresses into a material. These hidden stresses can cause a part to warp or distort over time or, more critically, during subsequent manufacturing steps. Annealing provides a controlled way to relax and eliminate these stresses, ensuring dimensional stability.

Improving Material Properties

By creating a more uniform and refined crystalline structure, annealing primarily increases ductility (the ability to be drawn or deformed without breaking) and toughness. This makes the material easier to machine and form. In some cases, it can also improve a material's electrical conductivity.

How Induction Changes the Annealing Process

While the metallurgical goal of annealing remains the same, using induction as the heating source fundamentally changes the speed, efficiency, and control of the process.

The Principle of Induction Heating

Induction annealing uses an alternating electric current passed through a copper coil. This creates a powerful, alternating magnetic field around the coil. When a metal part is placed within this field, the field induces electrical currents (called eddy currents) within the part itself. The material's natural resistance to these currents generates precise and rapid heat.

Unmatched Speed and Precision

Because heat is generated inside the part rather than being applied from an external source like a furnace, the target temperature is reached in seconds or minutes, not hours. This heating can also be highly localized. By designing the induction coil correctly, you can anneal a specific section of a component—such as a weld seam or a bend—without altering the properties of the rest of the part.

The Process: Heat, Soak, and Cool

The induction annealing cycle follows the same three classic stages, but with far greater control:

- Heating: The part is rapidly brought to its specific annealing temperature using the induction coil.

- Soaking: The part is held at this temperature for a precisely controlled duration, allowing the internal crystal structure to recrystallize and stresses to be relieved.

- Cooling: The part is then allowed to cool at a controlled, often slow, rate to ensure the desired soft and ductile structure is formed.

Understanding the Trade-offs of Induction Annealing

Induction annealing offers clear benefits but is not the universal solution for every application. Understanding its advantages and limitations is key to making the right choice.

Benefit: Speed and Repeatability

The process is extremely fast and digitally controlled, making it ideal for integration into automated production lines. Once a heating profile is established, it can be repeated thousands of times with virtually no variation, ensuring exceptional quality control.

Benefit: Energy Efficiency and Localized Treatment

Induction heating is highly efficient because it only heats the part, not a massive furnace chamber. The ability to perform selective annealing on a specific area of a large or complex component is a unique advantage that saves time, energy, and preserves the desired hardness in other areas.

Consideration: Equipment and Coil Design

The primary investment is in the induction power supply and the custom-fabricated copper coils. Each unique part geometry requires a specifically designed coil to ensure uniform and efficient heating. This upfront engineering and cost can be a barrier for low-volume or highly varied production runs.

Consideration: Not Ideal for Bulk Processing

While excellent for treating parts in a continuous flow, induction is less practical for annealing a large batch of small, randomly oriented parts simultaneously. In that scenario, a traditional batch furnace is often more economical and straightforward.

Making the Right Choice for Your Application

Selecting the correct annealing method depends entirely on your production goals, part geometry, and required throughput.

- If your primary focus is high-volume, continuous production: Induction annealing is ideal due to its speed, repeatability, and ease of automation.

- If your primary focus is selective or localized annealing: Induction is the superior, and often only, choice for treating specific zones on a part without affecting the whole.

- If your primary focus is general-purpose stress relief on diverse parts: A traditional furnace may be more flexible and cost-effective if speed is not the primary driver and part geometries vary widely.

Ultimately, choosing induction annealing is a strategic decision to leverage speed, precision, and control in your manufacturing process.

Summary Table:

| Aspect | Induction Annealing | Traditional Furnace Annealing |

|---|---|---|

| Heating Method | Internal heat generation via eddy currents | External heat from a furnace chamber |

| Speed | Very fast (seconds/minutes) | Slow (hours) |

| Precision/Localization | Excellent for selective areas | Heats the entire part/batch |

| Best For | High-volume production, automation, selective treatment | Bulk processing, diverse part geometries |

Ready to enhance your manufacturing process with the speed and precision of induction annealing?

KINTEK specializes in advanced lab and production equipment, including induction heating systems. Our solutions are designed to help you achieve superior material properties, improve production throughput, and ensure repeatable quality control.

Contact our experts today to discuss how an induction annealing system can be tailored to your specific metalworking needs!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is the high temperature of a tube furnace? Unlock the Right Model for Your Application

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis