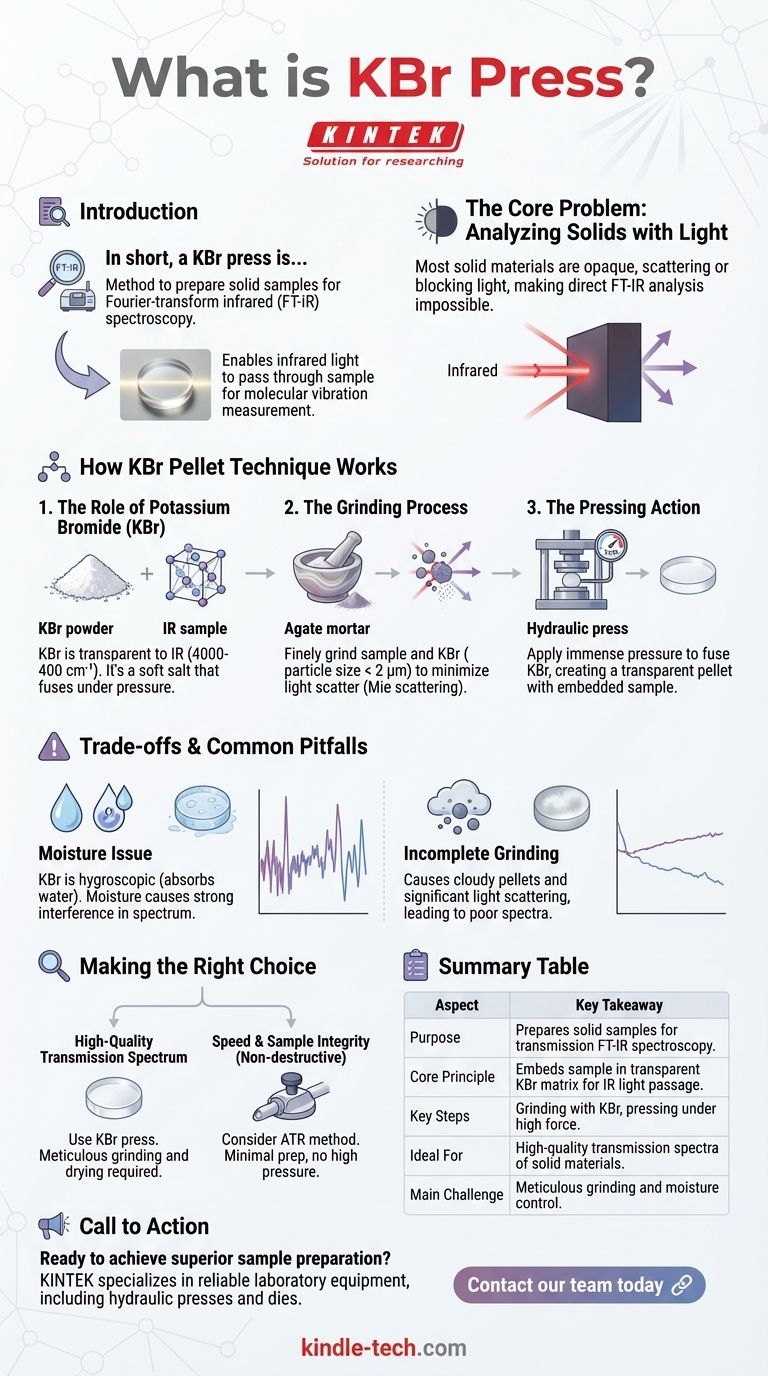

In short, a KBr press is a method used to prepare solid samples for analysis via Fourier-transform infrared (FT-IR) spectroscopy. The technique involves finely grinding a small amount of sample with potassium bromide (KBr) powder and then using a hydraulic press to compress the mixture into a thin, transparent pellet. This allows infrared light to pass through the sample, enabling the measurement of its molecular vibrations.

The core challenge in analyzing solid materials with infrared light is their opacity. The KBr press technique solves this by embedding the opaque sample particles into a transparent salt matrix, creating a "window" through which the material can be analyzed.

The Core Problem: Analyzing Solids with Light

FT-IR spectroscopy is a powerful analytical technique that identifies chemical bonds within a molecule by measuring how they absorb infrared light. For this to work, the infrared beam must be able to pass through the sample.

While liquids and gases can often be analyzed directly, most solid materials are opaque. They scatter or block light, making direct analysis impossible. The KBr pellet method is a classic solution to this fundamental problem.

How the KBr Pellet Technique Works

The entire process is designed to transform a powdered, opaque solid into a glassy, transparent disc suitable for spectroscopic analysis. This is achieved through three critical steps.

The Role of Potassium Bromide (KBr)

The choice of potassium bromide is deliberate. It has two essential properties:

- It is transparent to infrared radiation in the typical analysis range (4000-400 cm⁻¹), meaning it doesn't have its own signal that would interfere with the sample's spectrum.

- It is a soft crystalline salt that, under high pressure, will "flow" and fuse into a solid, glass-like sheet.

This process, known as cold-flowing, effectively encapsulates the sample particles within a solid, transparent KBr matrix.

The Grinding Process: Minimizing Light Scatter

Before pressing, the sample must be intimately mixed and ground with the KBr powder, typically using an agate mortar and pestle. The goal is to reduce the sample's particle size to less than the wavelength of the infrared light being used (typically <2 µm).

Failing to achieve this fine particle size results in significant light scattering (Mie scattering), which causes a poor-quality spectrum with a sloping baseline and reduced signal clarity.

The Pressing Action: Creating a Transparent Disc

The ground powder is loaded into a specialized die set. This set is then placed into a hydraulic press, where a force of several tons is applied.

This immense pressure forces the KBr salt crystals to deform and fuse together, trapping the finely ground sample particles in fixed positions. When the pressure is released, the result is a thin, translucent or transparent pellet that can be placed directly in the spectrometer's sample holder.

Understanding the Trade-offs and Common Pitfalls

While powerful, the KBr press method is meticulous and requires care to yield good results. Understanding its limitations is key to proper use.

The Critical Issue of Moisture

Potassium bromide is hygroscopic, meaning it readily absorbs water from the atmosphere. Water has very strong, broad absorption bands in the infrared spectrum.

If your KBr or sample is wet, or if you prepare the pellet in a humid environment, these water signals can obscure large portions of your sample's spectrum, making interpretation difficult or impossible. Using oven-dried KBr and working quickly is essential.

Incomplete Grinding and Cloudy Pellets

The most common sign of a poorly prepared pellet is a cloudy or opaque appearance. This is almost always due to insufficient grinding.

Large particles scatter light instead of transmitting it, leading to a noisy, unusable spectrum. A good pellet should be as clear as possible, similar to a small piece of glass.

Potential for Sample Degradation

The high pressures involved in forming the pellet can sometimes alter the sample itself. This is particularly true for polymorphic materials, where pressure can induce a change from one crystalline form to another, altering the resulting spectrum.

This interaction with the alkali halide (KBr) can also, in rare cases, cause a chemical reaction.

Making the Right Choice for Your Analysis

The KBr press is a foundational technique, but its use depends on your analytical goals.

- If your primary focus is a high-quality transmission spectrum: Take the time to meticulously dry your KBr, thoroughly grind your sample, and press a clear, transparent pellet. This remains the gold standard for many applications.

- If your primary focus is speed and sample integrity: Consider an alternative method like Attenuated Total Reflectance (ATR). ATR analysis requires minimal sample prep and avoids high pressure, making it much faster and non-destructive.

- If your primary focus is quantifying a sample component: The KBr pellet method can be used for quantitative analysis, but it requires precise weighing and highly repeatable preparation to ensure a consistent path length and concentration.

When executed correctly, the KBr press technique is an exceptionally powerful tool for revealing the chemical identity of solid materials.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Purpose | Prepares solid samples for transmission FT-IR spectroscopy. |

| Core Principle | Embeds sample particles in a transparent KBr matrix to allow infrared light to pass through. |

| Key Steps | Grinding sample with KBr, pressing under high force (tons). |

| Ideal For | High-quality transmission spectra of solid materials. |

| Main Challenge | Requires meticulous grinding and moisture control to avoid light scattering and water interference. |

Ready to achieve superior sample preparation for your FT-IR analysis?

The KBr press technique is fundamental for high-quality results, but it requires precision and the right equipment. KINTEK specializes in providing reliable laboratory equipment and consumables, including hydraulic presses and dies designed specifically for perfect pellet preparation.

Let our expertise help you eliminate common pitfalls like moisture interference and poor pellet clarity. Contact our team today to discuss your lab's specific needs and ensure your spectroscopic analyses are accurate and reproducible.

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- kbr pellet press 2t

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- Why is a laboratory hydraulic press essential for Ca3Co4O9 pelletizing? Optimize Pre-Sintering Mass Transport

- How do laboratory hydraulic presses facilitate biomass pelletization? Optimize Biofuel Density and Prevent Slagging

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why is a hydraulic pellet press used for FTIR? Transform Nanofillers into Clear Data

- How does a laboratory hydraulic pellet press contribute to SiCw/2024 aluminum composite preforms? Optimize Densification