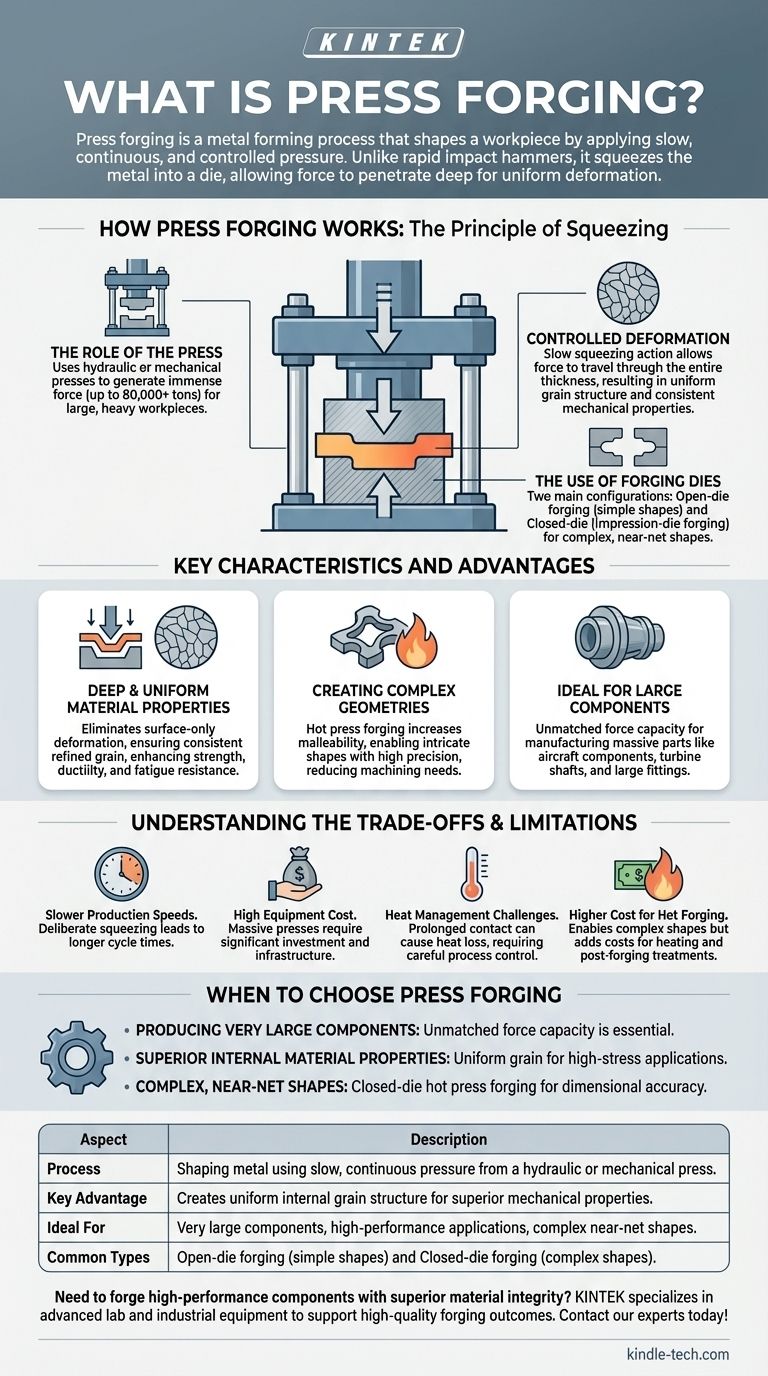

Press forging is a metal forming process that shapes a workpiece by applying slow, continuous, and controlled pressure. Unlike the rapid impacts of a hammer, a press squeezes the metal into a die, allowing the force to penetrate deep into the material for a more uniform deformation.

The core advantage of press forging lies in its ability to apply massive, sustained pressure. This method excels at creating very large components and achieving a uniform internal grain structure, which is critical for high-performance and safety-critical applications.

How Press Forging Works: The Principle of Squeezing

Press forging fundamentally relies on controlled force rather than kinetic energy. This distinction dictates its unique characteristics and applications.

The Role of the Press

The process uses either a hydraulic or mechanical press to generate the necessary force. Hydraulic presses are most common for this work, with capacities ranging from a few hundred tons to over 80,000 tons.

This immense power allows for the forging of exceptionally large and heavy workpieces, far beyond the capabilities of other methods.

Controlled Deformation

The key to press forging is the slow squeezing action. This deliberate application of pressure allows the force to travel through the entire thickness of the workpiece.

The result is a more uniform refinement of the metal's internal grain structure, leading to consistent and predictable mechanical properties throughout the part.

The Use of Forging Dies

Press forging can be performed using two main die configurations. Open-die forging uses simple, non-enclosing dies for large, relatively simple shapes.

Closed-die forging, also known as impression-die forging, uses dies that fully enclose the workpiece, forcing the metal to flow and fill a complex cavity to create a near-net shape.

Key Characteristics and Advantages

The slow and powerful nature of press forging delivers distinct benefits, particularly for demanding industrial components.

Deep and Uniform Material Properties

Because the force penetrates completely, press forging eliminates the surface-level-only deformation that can occur with impact methods. This ensures a consistent, refined grain structure, enhancing strength, ductility, and fatigue resistance.

Creating Complex Geometries

By applying heat, hot press forging significantly increases the material's malleability. This allows for the creation of intricate shapes with high precision, reducing the need for extensive secondary machining.

Ideal for Large Components

The sheer force capacity of forging presses makes them the go-to solution for manufacturing massive parts like aircraft structural components, turbine shafts, and large industrial fittings.

Understanding the Trade-offs and Limitations

While powerful, press forging is not the ideal solution for every scenario. It involves specific operational and economic considerations.

Slower Production Speeds

The deliberate squeezing process is inherently slower than the rapid blows of hammer forging. This can lead to longer cycle times and lower overall production rates for smaller components.

High Equipment Cost

The massive hydraulic presses required for this work represent a significant capital investment. The infrastructure needed to support such machinery is also substantial.

Heat Management Challenges

In hot forging, the prolonged contact between the hot workpiece and the cooler dies can lead to significant heat loss. This requires careful process control to maintain the material's optimal forging temperature.

Higher Cost for Hot Forging

As noted, hot forging enables complex shapes but adds costs. The process requires advanced electric heating systems and often involves post-forging fixture quenching to secure the part's final properties, increasing overall expense.

When to Choose Press Forging

Selecting the right forging method depends entirely on the component's requirements for size, material integrity, and complexity.

- If your primary focus is producing very large components: Press forging is often the only viable method due to its unmatched force capacity.

- If your primary focus is superior internal material properties: The slow, penetrating pressure is ideal for creating the uniform grain structure required in high-stress applications.

- If your primary focus is creating complex, near-net shapes with high precision: Closed-die hot press forging provides excellent dimensional accuracy, minimizing material waste and post-processing.

Ultimately, selecting press forging is a strategic decision for applications where material integrity, precision, and component scale are paramount.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Shaping metal using slow, continuous pressure from a hydraulic or mechanical press. |

| Key Advantage | Creates uniform internal grain structure for superior mechanical properties. |

| Ideal For | Very large components, high-performance applications, and complex near-net shapes. |

| Common Types | Open-die forging (simple shapes) and Closed-die forging (complex shapes). |

Need to forge high-performance components with superior material integrity? KINTEK specializes in advanced lab and industrial equipment, including solutions for material testing and processing that support high-quality forging outcomes. Our expertise helps ensure your materials meet the strictest standards for strength and durability. Contact our experts today to discuss how we can support your metal forming and testing requirements!

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What is the mechanism by which a laboratory hydraulic press facilitates the sintering of TiB2-SiC? Optimize Density

- What is the thickness of filter press cloth? Selecting the Right Cloth for Your Filtration Goals

- How does a laboratory hydraulic pellet press assist in the preparation of perovskite electrolyte green bodies?

- How is a sample prepared for XRF analysis? Master the Steps for Accurate Results

- What is the difference between KBr method and ATR method? Choose the Right FTIR Technique for Your Lab

- Why use a laboratory hydraulic press for metal powders? Achieve High-Density Green Bodies for Hot Pressing

- How is high temperature controlled in the hydraulic system? Prevent Damage and Boost Efficiency

- How much does a hydraulic press cost? A Complete Guide to Pricing from $200 to $1M+