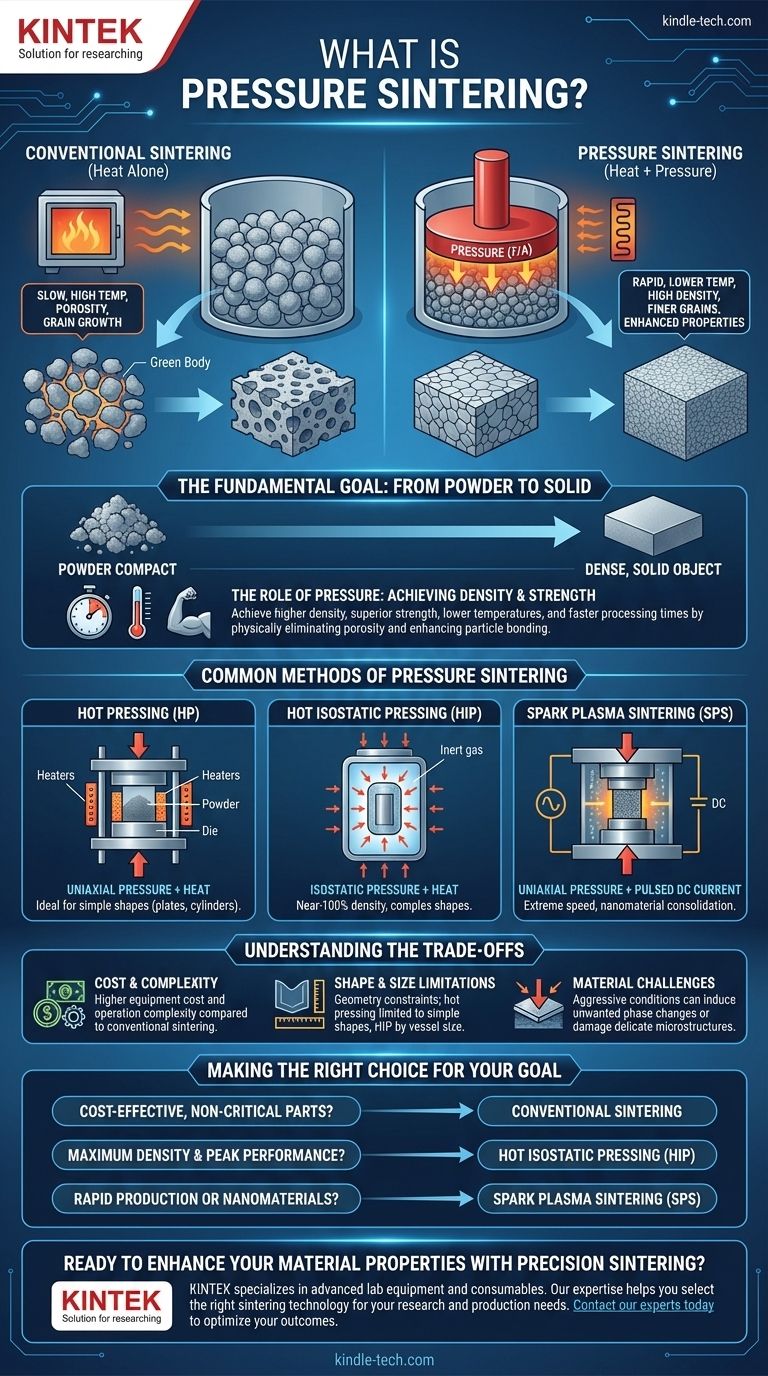

In essence, pressure sintering is a materials processing technique that combines high temperature with external mechanical pressure to transform a powder into a dense, solid object. Unlike conventional sintering which relies on heat alone, the addition of pressure physically forces the powder particles together, dramatically accelerating the densification process and improving the final material's properties.

The core purpose of using pressure in sintering is to achieve a denser, stronger final product at lower temperatures and in less time than is possible with heat alone. It overcomes the natural limitations of atomic diffusion by physically eliminating the empty spaces between powder particles.

The Fundamental Goal: From Powder to Solid

What is Conventional Sintering?

Conventional, or pressureless, sintering involves heating a compacted powder (known as a "green body") to a high temperature, typically below its melting point. At this temperature, atoms slowly diffuse across the boundaries of the particles, causing them to fuse together and gradually reduce the empty space, or porosity, within the material.

The Problem with Heat Alone

Relying solely on heat-driven diffusion is often slow and inefficient. To achieve high density, extremely high temperatures and long processing times are required. This high thermal exposure often leads to undesirable grain growth, where smaller crystals merge into larger ones, which can significantly weaken the final material.

How Adding Pressure Changes the Game

The Role of Pressure

Pressure is defined as a force applied over a specific area (P = F/A). In pressure sintering, this force is applied externally to the powder compact. This mechanical force does not wait for slow atomic diffusion to occur.

Enhanced Densification

The applied pressure provides an additional driving force for densification. It actively forces particles closer together, enhances plastic deformation at particle contact points, and physically closes the pores that heat alone struggles to eliminate. This results in a much denser and more uniform material structure.

Lower Temperatures and Finer Grains

Because pressure provides a powerful mechanism for densification, the process no longer needs to rely as heavily on high temperatures. Sintering can be performed at a lower temperature, which is critical for suppressing grain growth. The result is a material with a fine-grained microstructure, which typically translates to superior mechanical properties like hardness and strength.

Common Methods of Pressure Sintering

Hot Pressing (HP)

In Hot Pressing, a powder is placed in a die and pressure is applied along a single axis (uniaxial pressure) while it is heated. This is a relatively straightforward method ideal for producing simple, dense shapes like plates or cylinders.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing places a component in a high-temperature furnace that is also a high-pressure vessel. An inert gas, like argon, is used to apply uniform, equal pressure from all directions (isostatic pressure). This method is exceptionally effective at eliminating any remaining internal porosity and is used to create highly complex shapes with near-100% density.

Spark Plasma Sintering (SPS)

Also known as Field Assisted Sintering Technology (FAST), this advanced technique passes a pulsed DC electrical current directly through the powder and the die. This creates rapid, localized heating at the particle surfaces while uniaxial pressure is applied. SPS is extremely fast and highly effective at consolidating nanomaterials without causing grain growth.

Understanding the Trade-offs

Increased Equipment Cost and Complexity

The primary drawback of pressure sintering is the cost and complexity of the equipment. A hot press or HIP unit is significantly more expensive to purchase, operate, and maintain than a conventional furnace.

Shape and Size Limitations

While effective, pressure-assisted methods have geometric constraints. Hot pressing is generally limited to simple shapes that can be easily ejected from a die. Even HIP is limited by the internal size of the pressure vessel.

Material Processing Challenges

The combination of high pressure and temperature can be too aggressive for some materials. It can induce unwanted phase transformations or damage delicate microstructures if the process parameters are not precisely controlled.

Making the Right Choice for Your Goal

Your choice between pressureless and pressure-assisted sintering depends entirely on the required performance and cost constraints for your component.

- If your primary focus is cost-effectiveness for non-critical parts: Conventional, pressureless sintering is often sufficient and significantly cheaper.

- If your primary focus is maximum density and peak mechanical performance: Hot Isostatic Pressing (HIP) is the gold standard for creating nearly perfect, high-strength components.

- If your primary focus is rapid production or consolidating nanomaterials: Spark Plasma Sintering (SPS) offers unmatched speed and control over the final microstructure.

By understanding the interplay of heat and pressure, you can select the precise manufacturing path to achieve your desired material properties.

Summary Table:

| Method | Pressure Type | Key Advantage | Ideal For |

|---|---|---|---|

| Hot Pressing (HP) | Uniaxial | Simple, cost-effective | Simple shapes (plates, cylinders) |

| Hot Isostatic Pressing (HIP) | Isostatic (all directions) | Near-100% density, complex shapes | High-performance, critical components |

| Spark Plasma Sintering (SPS) | Uniaxial + Electrical Current | Extreme speed, nanomaterial consolidation | Rapid production, advanced materials |

Ready to enhance your material properties with precision sintering?

At KINTEK, we specialize in advanced lab equipment and consumables for materials processing. Whether you need to achieve maximum density with HIP, rapid production with SPS, or cost-effective solutions with hot pressing, our expertise can help you select the right technology for your laboratory's specific needs.

Contact our experts today to discuss how our sintering solutions can optimize your research and production outcomes.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the difference between hot pressing and sintering? Unlock the Right Process for Your Materials

- By what mechanism does a vacuum hot pressing furnace achieve densification? Mastery of Alloy Microstructure

- How does a vertical vacuum hot pressing furnace contribute to the final molding of graphite film and copper composite materials? Enhance Thermal Conductivity and Density

- What are the steps in the hot pressing process? Achieve Maximum Density for Complex Parts

- What effect does a high-vacuum environment in a hot-press furnace have on Mo-Na alloys? Achieve Pure Microstructures