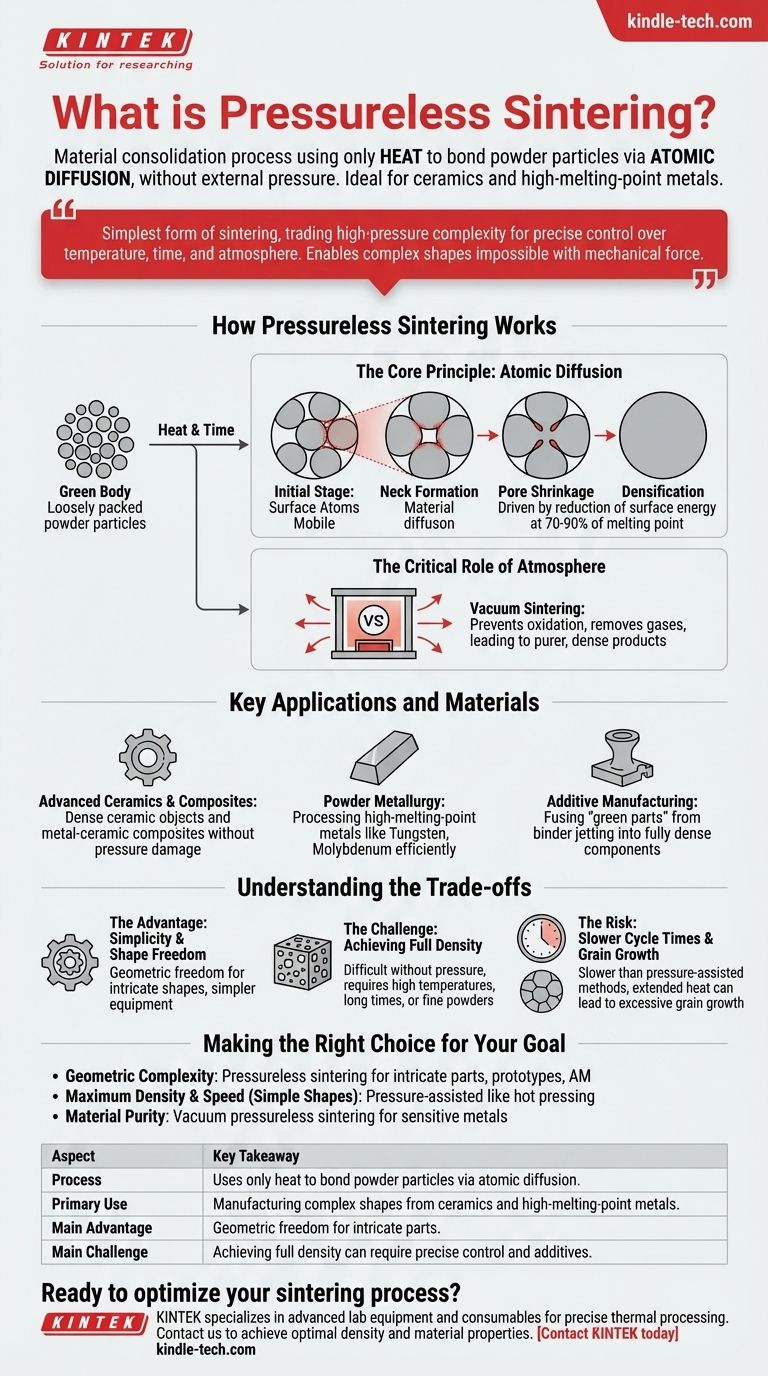

In short, pressureless sintering is a material consolidation process that uses only heat to bond powder particles into a solid mass. Unlike other methods, it relies entirely on atomic diffusion driven by high temperatures to densify the material, without applying any external mechanical pressure. This technique is fundamental to manufacturing parts from ceramics and high-melting-point metals.

Pressureless sintering is the simplest form of sintering, trading the complexity of high-pressure equipment for the need of precise control over temperature, time, and atmosphere. Its primary advantage is the ability to form complex shapes that are impossible to create with methods requiring mechanical force.

How Pressureless Sintering Works

Pressureless sintering is not a passive process. It is a highly controlled thermal treatment designed to transform a loosely packed powder, known as a "green body," into a dense, solid object with useful mechanical properties.

The Core Principle: Atomic Diffusion

The driving force behind sintering is the reduction of surface energy. At high temperatures (typically 70-90% of the material's melting point), atoms on the surfaces of individual powder particles become highly mobile.

These atoms diffuse across the contact points between particles, forming "necks" that grow over time. As this process continues, the necks merge, the pores between particles shrink, and the entire component densifies and strengthens.

The Critical Role of Atmosphere

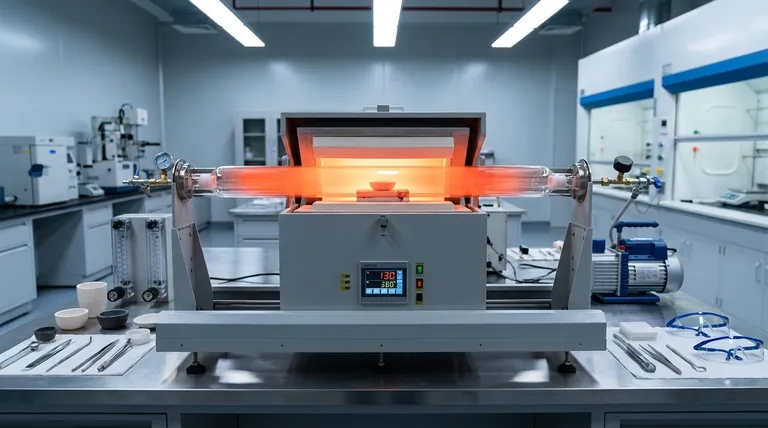

While no external pressure is applied, the atmosphere inside the furnace is a critical process variable. The most common environment is a vacuum.

Vacuum sintering involves placing the component in a furnace and removing the air before heating. This prevents oxidation of the material and helps pull out gases released from the powder during heating, leading to a purer, more densely sintered product with stable performance.

Key Applications and Materials

The simplicity and flexibility of pressureless sintering make it suitable for a wide range of advanced applications where other methods fall short.

Advanced Ceramics and Composites

Pressureless sintering is the traditional and most common method for creating dense ceramic objects. It is also used for metal-ceramic composites, where applying high pressure could damage the delicate microstructures.

Powder Metallurgy

This technique is essential for processing metals with extremely high melting points, such as tungsten or molybdenum. Melting and casting these metals is energy-intensive and difficult, whereas sintering their powders is far more practical and efficient.

Additive Manufacturing (3D Printing)

Many metal 3D printing processes, like binder jetting, produce a "green part" made of metal powder held together by a binder. This part is then placed in a furnace for pressureless sintering to fuse the metal particles into a fully dense final component.

Understanding the Trade-offs

Choosing a manufacturing process requires a clear-eyed assessment of its benefits and drawbacks. Pressureless sintering offers significant advantages but also presents unique challenges.

The Advantage: Simplicity and Shape Freedom

The primary benefit is geometric freedom. Since no mechanical press is involved, engineers can design and manufacture highly complex and intricate shapes that would be impossible to form using pressure-assisted sintering. The equipment is also generally simpler and less expensive.

The Challenge: Achieving Full Density

Without pressure to force particles together, achieving near-100% density can be difficult. It often requires higher temperatures, longer sintering times, or the use of fine powders and special chemical additives (sintering aids) to promote diffusion.

The Risk: Slower Cycle Times and Grain Growth

Because it relies solely on heat and time, pressureless sintering can be a slower process than pressure-assisted methods. Furthermore, extended time at high temperatures can sometimes lead to excessive grain growth, which can negatively impact the final mechanical properties of the material.

Making the Right Choice for Your Goal

Selecting the correct sintering method depends entirely on your project's specific constraints and objectives.

- If your primary focus is geometric complexity: Pressureless sintering is the superior choice for creating intricate parts, prototypes, or components made via additive manufacturing.

- If your primary focus is maximum density and speed for simple shapes: A pressure-assisted method like hot pressing may be more efficient for high-volume production of simple geometries.

- If your primary focus is material purity for sensitive metals: Vacuum pressureless sintering is ideal, as it protects against oxidation and removes contaminants during the process.

Ultimately, pressureless sintering is a foundational tool in materials science that enables the creation of high-performance components when its principles and limitations are properly understood.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Process | Uses only heat to bond powder particles via atomic diffusion. |

| Primary Use | Manufacturing complex shapes from ceramics and high-melting-point metals. |

| Main Advantage | Geometric freedom for intricate parts. |

| Main Challenge | Achieving full density can require precise control and additives. |

Ready to optimize your sintering process?

At KINTEK, we specialize in providing the advanced lab equipment and consumables you need for precise thermal processing. Whether you're working with advanced ceramics, metal powders for additive manufacturing, or high-purity composites, our solutions ensure consistent, high-quality results.

Let our experts help you select the right furnace and accessories to achieve optimal density and material properties. Contact KINTEK today to discuss your specific laboratory requirements!

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What happens when quartz is heated? A Guide to Its Critical Phase Transitions and Uses

- What are the primary functions of high-precision tube furnaces in graphene growth? Achieve Defect-Free GS Synthesis

- Why are quartz tubes preferred for chromium powder combustion? Superior Heat Resistance & Optical Clarity

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan