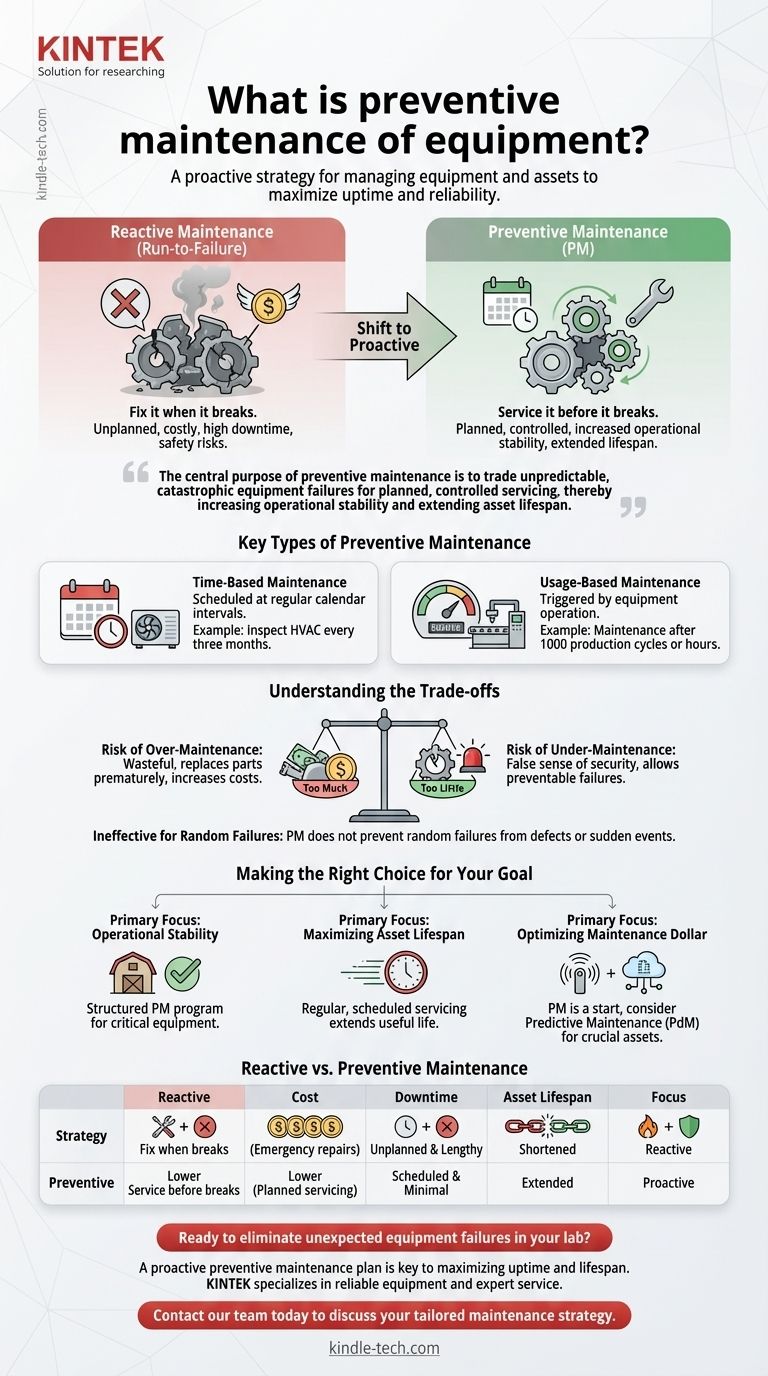

In essence, preventive maintenance is a proactive strategy for managing equipment and assets. It involves performing regular, scheduled maintenance tasks to identify and correct issues before they can cause an unexpected and costly failure. The core goal is to shift from a reactive "fix it when it breaks" model to a planned approach that maximizes uptime and reliability.

The central purpose of preventive maintenance is to trade unpredictable, catastrophic equipment failures for planned, controlled servicing, thereby increasing operational stability and extending asset lifespan.

The Core Principle: Moving from Reactive to Proactive

To understand the value of preventive maintenance (PM), it's crucial to first understand the alternative: reactive maintenance.

The Problem with "Run-to-Failure"

Reactive maintenance, also known as "run-to-failure," is the practice of only performing maintenance after a piece of equipment has already broken down.

While this approach requires minimal planning, it often results in chaotic, emergency repairs. These unplanned events lead to significant downtime, higher repair costs, and potential safety hazards.

The Preventive Maintenance Solution

Preventive maintenance is built on a simple premise: it is more efficient and less costly to service equipment on a set schedule than it is to deal with the consequences of an unexpected breakdown.

Think of it like changing the oil in your car. You don't wait for the engine to seize; you change the oil every 5,000 miles to prevent that catastrophic failure from ever happening.

Key Types of Preventive Maintenance

PM is not a one-size-fits-all strategy. The schedule for maintenance activities is typically triggered by one of two factors.

Time-Based Maintenance

This is the most common form of PM, where tasks are scheduled at regular calendar intervals.

For example, a technician might inspect an HVAC unit every three months or lubricate a specific bearing on the first of every month, regardless of how much the equipment was used.

Usage-Based Maintenance

This approach triggers maintenance based on actual equipment operation. The trigger could be hours of operation, production cycles, or miles driven.

This method is often more precise than time-based PM, as it ensures maintenance is performed only when necessary based on actual wear and tear.

Understanding the Trade-offs

While highly effective, a preventive maintenance program is a strategic investment with its own set of challenges and limitations. It is not a perfect solution for every situation.

The Risk of Over-Maintenance

Performing maintenance too frequently can be wasteful. You may replace parts that still have significant useful life remaining, unnecessarily increasing labor and material costs.

The Risk of Under-Maintenance

Conversely, setting your maintenance intervals too far apart defeats the entire purpose of the program. This can create a false sense of security while still allowing preventable failures to occur.

Ineffective for Random Failures

Preventive maintenance is most effective for failures that are related to age or use. It is not designed to prevent random equipment failures caused by hidden defects or sudden external events.

Making the Right Choice for Your Goal

Adopting a preventive maintenance strategy is a foundational step toward operational excellence. The key is to apply it thoughtfully to the right assets.

- If your primary focus is operational stability and avoiding surprise shutdowns: A structured PM program for your critical equipment is the most effective way to ensure reliability.

- If your primary focus is maximizing asset lifespan: Regular, scheduled servicing is proven to extend the useful life of machinery and reduce the need for premature replacement.

- If your primary focus is optimizing every maintenance dollar: PM is a strong start, but you may want to layer in predictive maintenance (PdM) for your most crucial assets to ensure work is only done when truly necessary.

Ultimately, preventive maintenance is a strategic investment in predictability and control over your operations.

Summary Table:

| Aspect | Reactive Maintenance | Preventive Maintenance (PM) |

|---|---|---|

| Strategy | Fix it when it breaks | Service it before it breaks |

| Cost | High (emergency repairs) | Lower (planned servicing) |

| Downtime | Unplanned & lengthy | Scheduled & minimal |

| Asset Lifespan | Shortened | Extended |

| Focus | Reactive | Proactive |

Ready to eliminate unexpected equipment failures in your lab?

A proactive preventive maintenance plan is key to maximizing the uptime and lifespan of your critical lab equipment. KINTEK specializes in supporting laboratory operations with reliable equipment and expert service.

Contact our team today to discuss how we can help you develop a tailored maintenance strategy that ensures your lab runs smoothly and efficiently.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- CVD Diamond Dressing Tools for Precision Applications

People Also Ask

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance