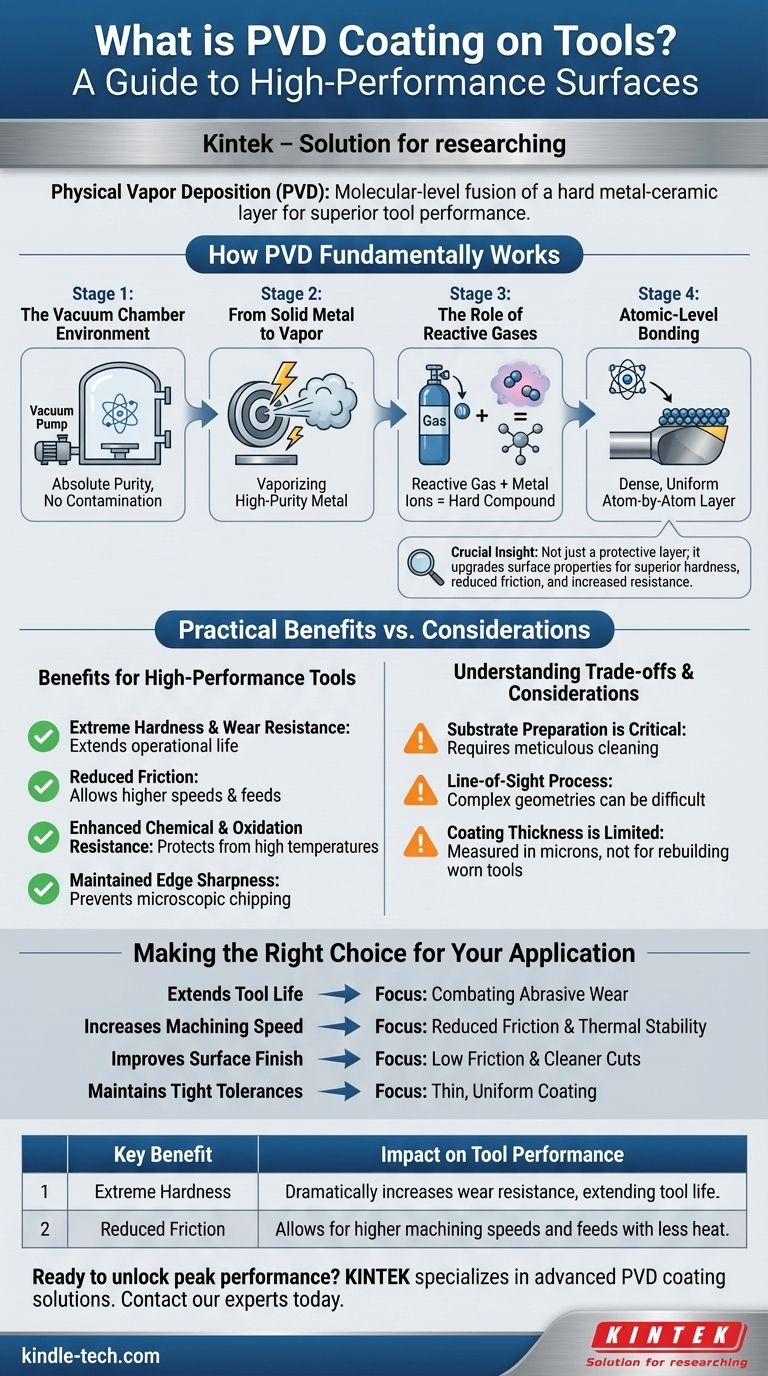

At its core, Physical Vapor Deposition (PVD) coating is a high-tech vacuum process that bonds an extremely thin but incredibly hard layer of a metal-ceramic material onto the surface of a tool. This is not paint or plating; it is a molecular-level fusion. The process involves vaporizing a solid metal, such as titanium or chromium, and reacting it with a gas like nitrogen to deposit a durable, performance-enhancing film atom by atom.

The crucial insight is that PVD is not just a protective layer; it fundamentally upgrades the tool's surface properties. It directly translates to superior hardness, reduced friction, and increased resistance to heat and wear, enabling tools to last longer and perform at higher speeds.

How PVD Fundamentally Works

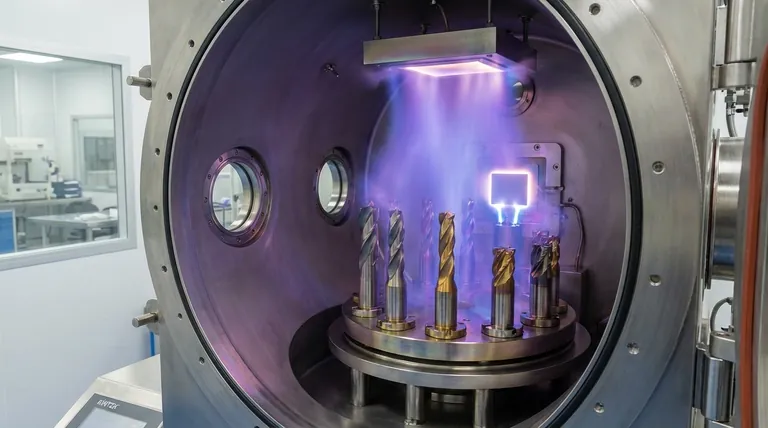

To understand the value of PVD, you must first understand the precision of the process. It takes place within a sealed vacuum chamber to ensure absolute purity and prevent contamination.

The Vacuum Chamber Environment

Everything starts in a vacuum. By removing nearly all the air, the process ensures that the vaporized coating material travels directly to the tool without reacting with oxygen or other contaminants, which would create a weak, impure layer.

From Solid Metal to Vapor

A solid, high-purity metal, known as a "target" (e.g., titanium), is vaporized inside the chamber. This is typically achieved using a high-energy process like ion bombardment (sputtering) or a powerful electric arc that effectively turns the solid metal into a plasma cloud.

The Role of Reactive Gases

As the metal ions travel toward the tools, a precisely controlled reactive gas, most commonly nitrogen, is introduced. The metal ions react with the gas in the plasma, forming a new, extremely hard compound—for example, titanium nitride (TiN).

Atomic-Level Bonding

This newly formed compound deposits onto the tools atom by atom. It creates a dense, bonded layer that is almost impossible to separate from the base material. The result is a uniform coating that conforms perfectly to the tool's geometry, including sharp cutting edges.

The Practical Benefits for High-Performance Tools

Applying a PVD coating directly enhances the capabilities of cutting tools, molds, and other wear components in measurable ways.

Extreme Hardness and Wear Resistance

The primary benefit is a dramatic increase in surface hardness. This coating acts as a barrier that resists the abrasive forces encountered during cutting, extending the operational life of the tool significantly.

Reduced Friction

PVD coatings are inherently smoother than the tool steel beneath them. This lower coefficient of friction means less heat generation at the cutting edge, allowing for higher machining speeds and feeds without risking tool failure.

Enhanced Chemical and Oxidation Resistance

The coating creates a thermal barrier, protecting the tool from the high temperatures that cause material degradation and oxidation. This is critical when working with difficult-to-machine alloys or in high-speed operations.

Maintained Edge Sharpness

By providing rigid support directly at the cutting edge, the coating prevents the microscopic chipping and dulling that initiates tool failure. This allows the tool to maintain its sharpness for a much longer period.

Understanding the Trade-offs and Considerations

While powerful, PVD is a sophisticated process with specific requirements. Objectivity demands acknowledging its limitations.

Substrate Preparation is Critical

The coating's adhesion is only as good as the surface it's applied to. The tool must be meticulously cleaned and free of any contaminants. Any failure in pre-treatment will result in the coating flaking or peeling.

It's a Line-of-Sight Process

The vaporized material travels in a straight line. Therefore, the tools must be carefully fixtured and rotated within the chamber to ensure all critical surfaces are evenly coated. Deep, narrow holes or complex internal channels can be difficult to coat.

Coating Thickness is Limited

PVD coatings are extremely thin, typically measured in microns (thousandths of a millimeter). They are designed to resist wear, not to rebuild a worn or damaged surface. They cannot compensate for a poorly made or already damaged tool.

Making the Right Choice for Your Application

Selecting a PVD coating should be driven by a specific performance goal.

- If your primary focus is extending tool life: PVD is a direct solution for combating abrasive wear, especially when machining tough or abrasive materials.

- If your primary focus is increasing machining speed: The reduced friction and thermal stability of PVD coatings enable higher cutting speeds and feed rates, increasing productivity.

- If your primary focus is improving surface finish: A PVD-coated tool's low friction and resistance to material buildup on the edge can lead to a cleaner cut and a better finish on the workpiece.

- If your primary focus is maintaining tight tolerances: The coating is exceptionally thin and uniform, ensuring it does not significantly alter the tool's geometry or cutting dimensions.

Ultimately, PVD coating transforms a standard tool into a high-performance instrument by re-engineering its surface for maximum durability and efficiency.

Summary Table:

| Key Benefit | Impact on Tool Performance |

|---|---|

| Extreme Hardness | Dramatically increases wear resistance, extending tool life. |

| Reduced Friction | Allows for higher machining speeds and feeds with less heat. |

| Heat & Oxidation Resistance | Protects tools from degradation in high-temperature operations. |

| Maintained Edge Sharpness | Prevents microscopic chipping, ensuring consistent performance. |

Ready to unlock peak performance for your tools? KINTEK specializes in advanced PVD coating solutions for laboratory and industrial cutting tools and components. Our coatings are engineered to deliver superior hardness, reduced friction, and extended tool life, directly boosting your productivity and reducing costs. Contact our experts today to discuss how we can enhance your specific application.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition