At its core, the theory of Physical Vapor Deposition (PVD) describes a process where a solid material is converted into a vapor within a vacuum, transported atom-by-atom, and then condensed onto a substrate to form a high-performance thin film. Unlike a simple paint or plating, PVD is a line-of-sight, atomistic process that builds a new surface layer with exceptional purity, adhesion, and specific engineered properties.

The central principle of PVD is not a chemical reaction, but a physical transformation. It involves moving a material from a solid source (target) to a final solid coating by passing it through a vapor phase in a highly controlled vacuum environment.

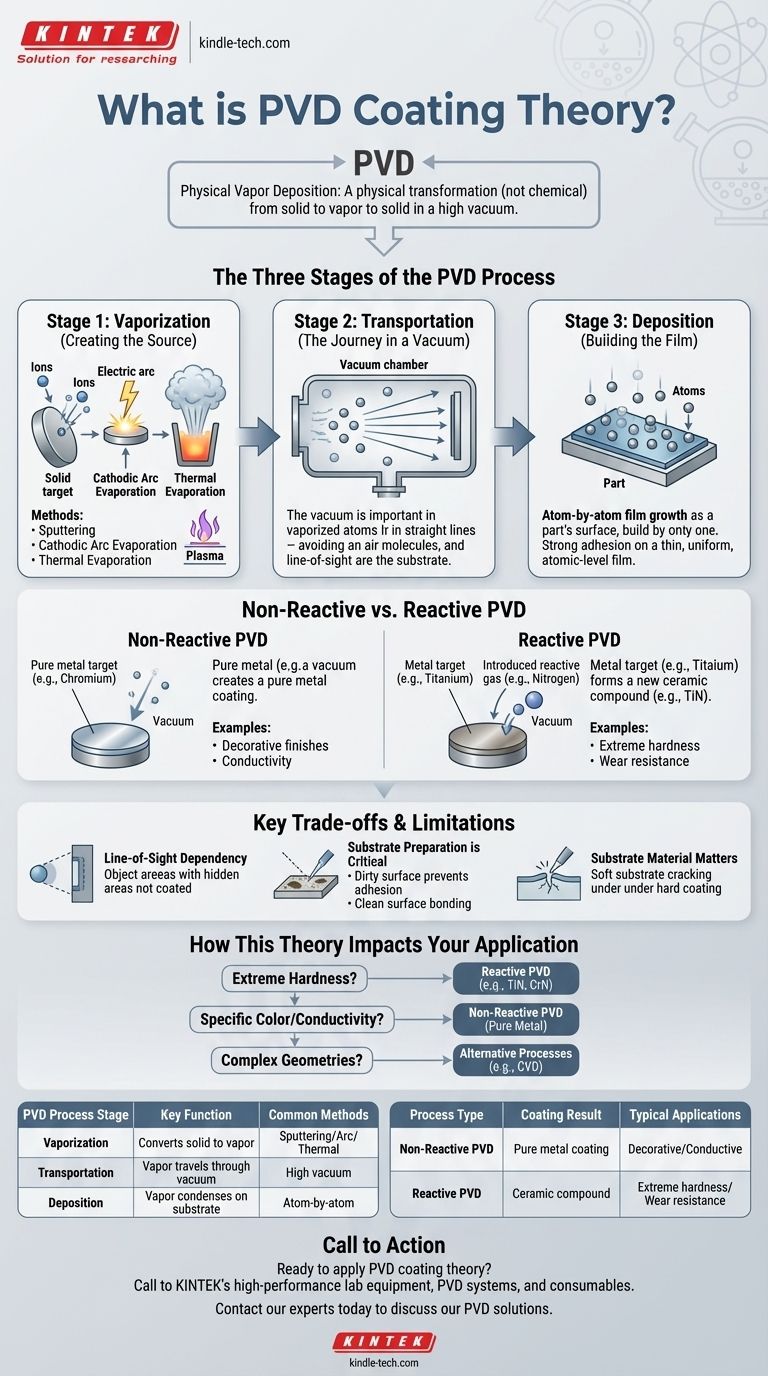

The Three Stages of the PVD Process

To understand the theory, it's best to break the process down into its three fundamental stages. These stages all occur inside a sealed vacuum chamber, a critical element that prevents contamination from atmospheric gases.

Stage 1: Vaporization (Creating the Source)

This is the step where the solid coating material, known as a target, is converted into a gas. The method used for vaporization is one of the primary ways PVD processes are categorized.

Common methods include:

- Sputtering: The target is bombarded with high-energy ions (often from a gas like argon) in a plasma. This bombardment physically knocks atoms off the target's surface, launching them into the vacuum chamber.

- Cathodic Arc Evaporation: A high-current electric arc is moved across the target's surface, causing localized melting and evaporation that generates a highly ionized vapor.

- Thermal Evaporation: The source material is heated in a crucible, either by resistance or an electron beam, until it evaporates.

Stage 2: Transportation (The Journey in a Vacuum)

Once the atoms are liberated from the target, they travel in a straight line through the vacuum chamber. The vacuum is essential for this step.

Without it, the vaporized atoms would collide with air molecules, losing energy and potentially reacting with oxygen or nitrogen in an uncontrolled way. The vacuum ensures a clean, direct path from the source to the substrate.

Stage 3: Deposition (Building the Film)

When the vaporized atoms reach the surface of the part being coated (the substrate), they condense back into a solid state. This deposition happens atom by atom, creating a thin, highly uniform, and dense film that bonds tightly to the substrate's surface.

Non-Reactive vs. Reactive PVD

The true versatility of PVD theory comes from a crucial distinction in how the process is applied. This choice fundamentally changes the final coating's properties.

Non-Reactive PVD

In its purest form, PVD is a direct physical transfer. If the target is pure chromium and the vacuum is clean, the coating that forms on the substrate will also be pure chromium. This is used for creating decorative chrome finishes or conductive layers.

Reactive PVD

To create exceptionally hard, ceramic-like coatings, a reactive gas (such as nitrogen, oxygen, or methane) is intentionally introduced into the vacuum chamber.

The vaporized metal atoms from the target react with this gas during their journey or upon arrival at the substrate. This forms an entirely new compound. For example, vaporized titanium (a metal) reacts with introduced nitrogen gas to form titanium nitride (TiN), a very hard, gold-colored ceramic.

Understanding the Key Trade-offs

While powerful, the physical principles behind PVD introduce specific limitations that must be considered.

Line-of-Sight Dependency

Because the vaporized atoms travel in straight lines, PVD is a line-of-sight process. Surfaces that are hidden or inside deep, narrow cavities will not receive a uniform coating. This makes it ideal for planar surfaces or parts that can be rotated effectively during the process.

Substrate Preparation is Critical

The atomic-level bonding relies on an exceptionally clean surface. Any oils, oxides, or other contaminants on the substrate will prevent proper adhesion, leading to a weak or failed coating. This is why extensive multi-stage cleaning and pre-treatment are mandatory parts of any professional PVD workflow.

Substrate Material Matters

The PVD coating does not exist in isolation; it becomes part of a system with the substrate. The hardness and performance of the final product depend heavily on the underlying material's ability to support the thin, hard coating. A hard coating on a soft substrate can crack under pressure.

How This Theory Impacts Your Application

Understanding the core principles allows you to select the right approach based on your end goal.

- If your primary focus is extreme hardness and wear resistance: You need a reactive PVD process to form a ceramic compound like Titanium Nitride (TiN) or Chromium Nitride (CrN).

- If your primary focus is a specific color, decorative finish, or electrical conductivity: A non-reactive PVD process using a pure metal target like chromium, aluminum, or titanium is the correct path.

- If you are coating parts with complex internal geometries: You must recognize the line-of-sight limitation of PVD and may need to consider alternative processes like Chemical Vapor Deposition (CVD).

By understanding PVD as an atomic-level construction process, you can effectively leverage its capabilities for superior surface engineering.

Summary Table:

| PVD Process Stage | Key Function | Common Methods |

|---|---|---|

| Vaporization | Converts solid target into vapor | Sputtering, Cathodic Arc, Thermal Evaporation |

| Transportation | Vapor travels through vacuum | Requires high vacuum for clean path |

| Deposition | Vapor condenses on substrate | Atom-by-atom film growth |

| Process Type | Coating Result | Typical Applications |

| Non-Reactive PVD | Pure metal coating (e.g., Chromium) | Decorative finishes, Electrical conductivity |

| Reactive PVD | Ceramic compound (e.g., TiN, CrN) | Extreme hardness, Wear resistance |

Ready to apply PVD coating theory to enhance your products?

KINTEK specializes in high-performance lab equipment, including PVD systems and consumables, to help you achieve superior surface engineering results. Whether you need extreme wear resistance, specific decorative finishes, or conductive layers, our expertise ensures you select the right process and materials for your specific substrate and application.

Contact our experts today to discuss how our PVD solutions can bring durable, high-quality coatings to your laboratory or manufacturing process.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition