In short, sintered metal is used to manufacture a vast range of components, from high-performance structural parts in cars to porous filters and self-lubricating bearings. It is a powder metallurgy process valued for its ability to create complex shapes from materials with very high melting points, such as tungsten and molybdenum.

The core reason to choose sintering is not for a single application, but for its unique manufacturing control. It allows engineers to build parts below their melting point, create intricate geometries with minimal waste, and precisely engineer material properties like density and porosity for specific functions.

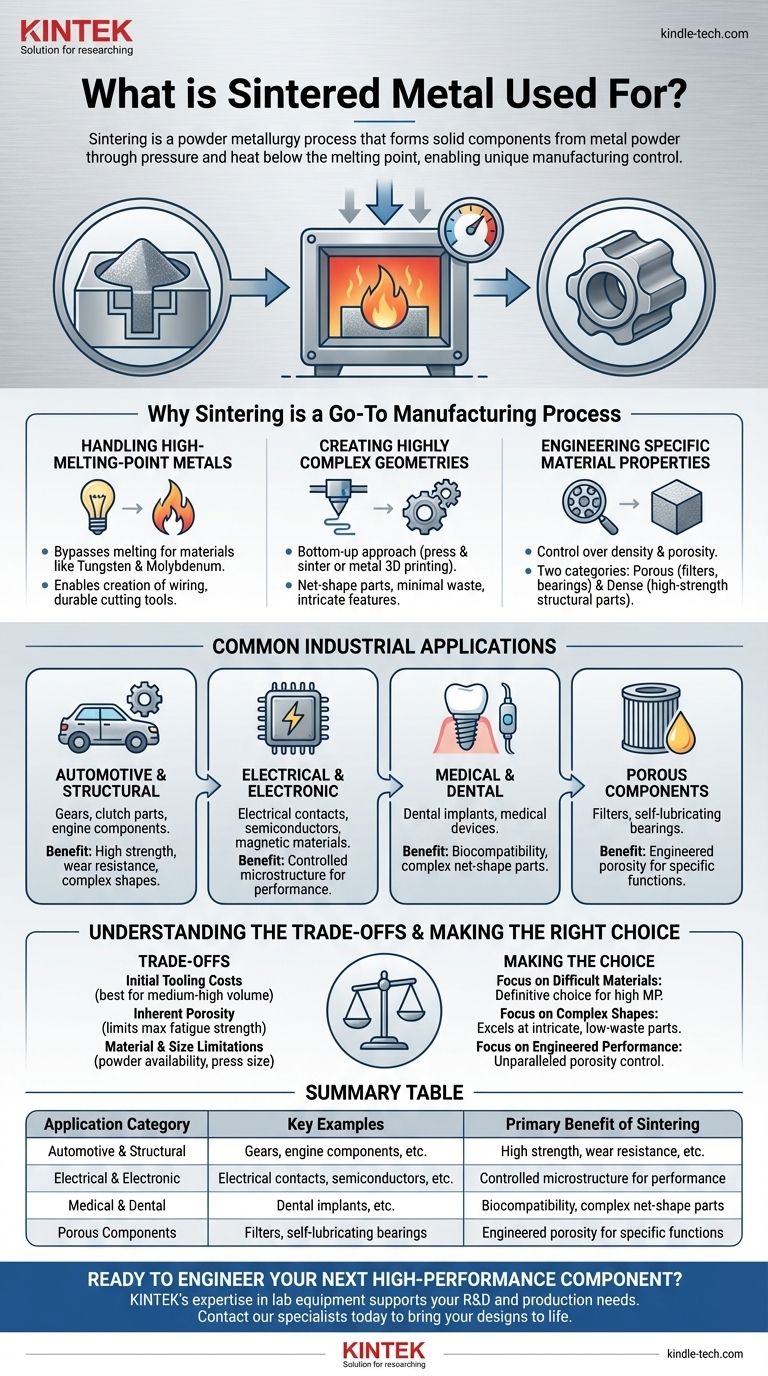

Why Sintering is a Go-To Manufacturing Process

Sintering is a thermal process that applies pressure and heat to a powdered material to form a solid mass. Crucially, this happens below the material's melting point. This fundamental principle is what unlocks its key advantages.

Handling High-Melting-Point Metals

Most manufacturing methods, like casting, require melting the base material. This is impractical or extremely energy-intensive for metals with very high melting points, like tungsten or molybdenum.

Sintering bypasses this challenge entirely, enabling the creation of components like tungsten wiring for lighting or durable cutting tools that would otherwise be nearly impossible to form.

Creating Highly Complex Geometries

Sintering begins with a powder, which can be pressed into a mold (die) or selectively fused layer-by-layer, as in metal 3D printing.

This "bottom-up" approach allows for the creation of highly complex internal and external features with exceptional precision. It's an efficient way to produce parts that would be difficult, wasteful, or impossible to create through traditional subtractive machining.

Engineering Specific Material Properties

The space between the initial powder particles creates porosity. Sintering reduces this, but the level of densification can be precisely controlled.

This control creates two distinct application categories:

- Porous Components: Intentionally leaving interconnected pores creates products like filters and self-lubricating bearings, which hold oil within their structure.

- Dense, High-Strength Components: For structural parts, the goal is to minimize porosity, which enhances strength, ductility, and thermal and electrical conductivity.

Common Industrial Applications of Sintered Metal

The versatility of sintering means its products are found across nearly every major industry.

Automotive and Structural Parts

The automotive industry is a primary user of sintered metal for producing gears, clutch parts, and engine components. The process delivers strong, wear-resistant parts with excellent dimensional tolerances at a high production rate.

Electrical and Electronic Components

Sintering is used to produce electrical contacts, semiconductors, and various magnetic materials. The ability to control the material's microstructure is key to achieving the desired electrical and magnetic performance.

Medical and Dental Products

Biocompatible metals like titanium can be sintered to create custom dental implants and medical devices. The process's ability to create complex, net-shape parts reduces the need for secondary machining, which is critical for these applications.

Understanding the Trade-offs

While powerful, sintering is not a universal solution. An objective evaluation requires acknowledging its limitations.

Initial Tooling Costs

For traditional press-and-sinter powder metallurgy, the cost of creating the initial hardened steel die can be substantial. This makes it most cost-effective for medium- to high-volume production runs where the tooling cost can be amortized over many parts.

Inherent Porosity

While sintering significantly increases density, achieving 100% of the theoretical material density is difficult and often requires secondary operations. This residual porosity can be a limiting factor for applications requiring the absolute maximum fatigue strength or fracture toughness.

Material and Size Limitations

The process is dependent on the availability of suitable metal powders. Furthermore, part size is often limited by the capacity of the presses and the size of the furnaces used in the process.

Making the Right Choice for Your Goal

Selecting a manufacturing process depends entirely on your project's specific priorities.

- If your primary focus is handling difficult materials: Sintering is the definitive choice for metals with extremely high melting points or for creating unique alloys not possible through melting.

- If your primary focus is manufacturing complex shapes efficiently: Sintering excels at producing intricate, net-shape parts with minimal material waste, especially for high-volume production.

- If your primary focus is engineered performance: Sintering offers unparalleled control over porosity, making it ideal for creating components like filters, bearings, or parts with specific density requirements.

Ultimately, sintering empowers you to build parts by design, not just by limitation.

Summary Table:

| Application Category | Key Examples | Primary Benefit of Sintering |

|---|---|---|

| Automotive & Structural | Gears, engine components, clutch parts | High strength, wear resistance, complex shapes |

| Electrical & Electronic | Electrical contacts, semiconductors, magnetic materials | Controlled microstructure for performance |

| Medical & Dental | Dental implants, medical devices | Biocompatibility, complex net-shape parts |

| Porous Components | Filters, self-lubricating bearings | Engineered porosity for specific functions |

Ready to Engineer Your Next High-Performance Component?

Sintering offers unparalleled control for creating complex, durable parts from challenging materials. Whether you need high-strength automotive components, custom medical implants, or precisely engineered porous filters, KINTEK's expertise in lab equipment and consumables can support your R&D and production needs.

Contact our specialists today to discuss how sintering can solve your specific manufacturing challenges and bring your designs to life with efficiency and precision.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Custom PTFE Teflon Parts Manufacturer for Acid and Alkali Resistant Chemical Powder Material Scoops

- Custom Boron Nitride (BN) Ceramic Parts

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What is the main source of biochar? Unlock the Power of Sustainable Feedstocks

- What is the standard heat treatment process? A Framework to Achieve Your Desired Material Properties

- What are the applications of XRD and XRF? Unlock the Difference Between Elemental and Structural Analysis

- What are the properties of sintered iron? Achieve High Strength & Precise Magnetic Performance

- What is the necessity of using a laboratory drying oven when processing MoO3/GO composite nanopowders? Find out here.

- What is the thin film method? A Guide to Advanced Surface Engineering

- How is a benchtop laboratory centrifuge used in the desorption and regeneration of composite adsorbent beads?

- What are the physical and chemical properties of graphite? A Unique Material for Extreme Applications