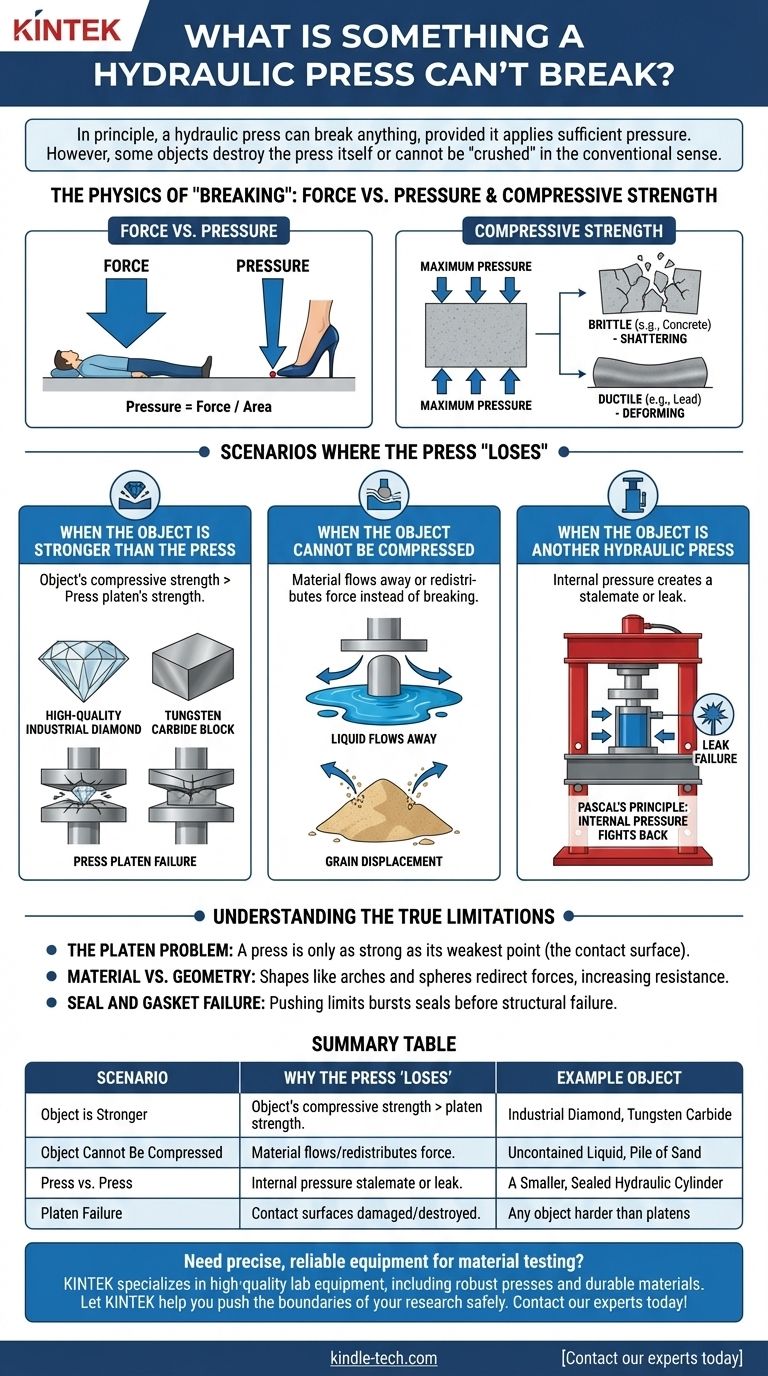

In principle, a hydraulic press can break anything, provided it can apply more pressure than the object can withstand. However, some objects will either destroy the press itself or are physically incapable of being "crushed" in the conventional sense. A sphere made of industrial diamond, for example, would likely shatter the press's steel platens, while a non-compressible fluid will simply flow away from the pressure.

The question is not about finding an "unbreakable" object, but understanding the limits of the press itself. An object resists being crushed when its compressive strength exceeds the pressure the press can generate, or when its physical state, like a liquid, doesn't allow for compressive failure.

The Physics of "Breaking"

To understand what a press can't break, we first must define what "breaking" means. It's a contest between the pressure applied by the press and the material's ability to resist that pressure.

Force vs. Pressure

A hydraulic press generates immense force. However, it is pressure—the force applied over a specific area—that causes an object to fail.

Think of it like this: a person's body weight (force) is distributed evenly when lying on the ground. But that same force concentrated onto the point of a stiletto heel (a tiny area) generates enormous pressure. Hydraulic presses work on the same principle, concentrating massive force onto the object.

Compressive Strength

Every material has a property called compressive strength. This is the maximum pressure it can withstand before it deforms or fractures.

When the pressure from the press exceeds the object's compressive strength, the object fails. For brittle materials like concrete, this means shattering. For ductile materials like lead, this means deforming and squashing.

Scenarios Where the Press "Loses"

An object "wins" against a hydraulic press not by being magically indestructible, but by exploiting the limits of physics and the press's own design.

When the Object is Stronger Than the Press

The components of a hydraulic press, specifically the steel plates that make contact with the object (the platen or anvil), have their own compressive strength.

If you place an object with a higher compressive strength than hardened steel between the platens, the press will fail first. A high-quality industrial diamond or a block of tungsten carbide would likely crack, shatter, or permanently dent the steel platens before breaking itself.

When the Object Cannot Be Compressed

You cannot "crush" a liquid or a gas in an unsealed environment. An uncontained pool of water or hydraulic fluid (which is, ironically, the very liquid that powers the press) cannot be broken.

The press would simply squeeze the liquid, forcing it to flow out and away from the pressure. The liquid remains fundamentally unchanged. The same is true for a pile of sand; the individual grains are hard, but the press's energy is spent displacing the grains, not breaking them.

When the Object is Another Hydraulic Press

A fascinating thought experiment involves pitting two hydraulic presses against each other. If you place a small, sealed hydraulic cylinder inside a larger press, you are fighting hydraulics with hydraulics.

As the large press compresses the small cylinder, the pressure inside the small cylinder will skyrocket according to Pascal's Principle. This internal pressure will push back against the larger press, potentially creating a stalemate or causing the smaller, weaker cylinder to fail and leak.

Understanding the True Limitations

The focus on the object is often misplaced. The real limitations lie with the machine itself.

The Platen Problem

A press is only as strong as its weakest point. In most cases, this is the surface that meets the object. Even a multi-ton press is rendered useless if its steel platens are destroyed by a small, super-hard object.

Material vs. Geometry

The shape of an object dramatically affects how it handles force. A solid block is easy to crush. However, an arch or a sphere is naturally designed to redirect compressive forces outward.

While a press would eventually break these shapes, their geometry provides a level of resistance far greater than their material's compressive strength alone would suggest.

Seal and Gasket Failure

Beyond catastrophic structural failure, a press can "lose" in a much more mundane way: by leaking. Hydraulic systems rely on a complex series of seals and gaskets to contain the fluid under extreme pressure.

Pushing a press beyond its design limits can cause these seals to burst long before the steel frame gives way. The press loses all its force, and the object survives, untouched.

Making the Right Choice for Your Goal

Instead of asking what's unbreakable, it's more useful to ask how different materials respond to immense pressure.

- If your primary focus is to find a material that will damage the press: Look for anything with a significantly higher compressive strength and hardness than hardened steel, such as industrial diamond, boron nitride, or tungsten carbide.

- If your primary focus is to find an object that won't "shatter": You are looking for non-solid materials. A sealed container of a non-compressible fluid like water or oil will resist crushing until the container itself fails.

- If your primary focus is to test the theoretical limits: Consider objects that are already in a state of extreme compression. Theoretically, you could not crush an object made of neutron star material, as it is already one of the densest and most pressure-resistant substances known to physics.

Understanding these core principles of force, pressure, and material science is far more powerful than simply knowing a list of "unbreakable" items.

Summary Table:

| Scenario | Why the Press 'Loses' | Example Object |

|---|---|---|

| Object is Stronger | Object's compressive strength exceeds the press's platen strength. | Industrial Diamond, Tungsten Carbide |

| Object Cannot Be Compressed | Material flows away or redistributes force instead of breaking. | Uncontained Liquid, Pile of Sand |

| Press vs. Press | Internal hydraulic pressure creates a stalemate or causes a leak. | A Smaller, Sealed Hydraulic Cylinder |

| Platen Failure | The press's own contact surfaces are damaged or destroyed. | Any object harder than the press's steel platens |

Need precise, reliable equipment for your material testing or lab work? Understanding the limits of force and pressure is critical for accurate results. At KINTEK, we specialize in high-quality lab equipment and consumables, including robust presses and durable materials designed to withstand extreme conditions. Our expertise ensures you get the right tools for your specific application, whether you're testing material strength or conducting precise experiments.

Let KINTEK help you push the boundaries of your research safely and effectively. Contact our experts today to discuss your laboratory needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the uniaxial pressing method? A Guide to High-Speed, Cost-Effective Powder Compaction

- How does it affect the performance of hydraulic machines? Maximize Your ROI with Precision Engineering

- Why use KBr to make the pellet? Achieve Clear, Accurate IR Spectroscopy Results

- What is the purpose of using a laboratory hydraulic press for LGVO synthesis? Achieve High-Purity Solid Electrolytes

- What is the use of a hydraulic pellet press? Transform Powders into Precise Samples for Analysis

- How does a laboratory hydraulic press contribute to g-CNT electrode preparation? Mastering Material Densification

- How does temperature affect hydraulic oil? Optimize Viscosity for Peak System Performance

- What role does a laboratory hydraulic press play in copper-graphite composite fabrication? Enhance Green Strength Now