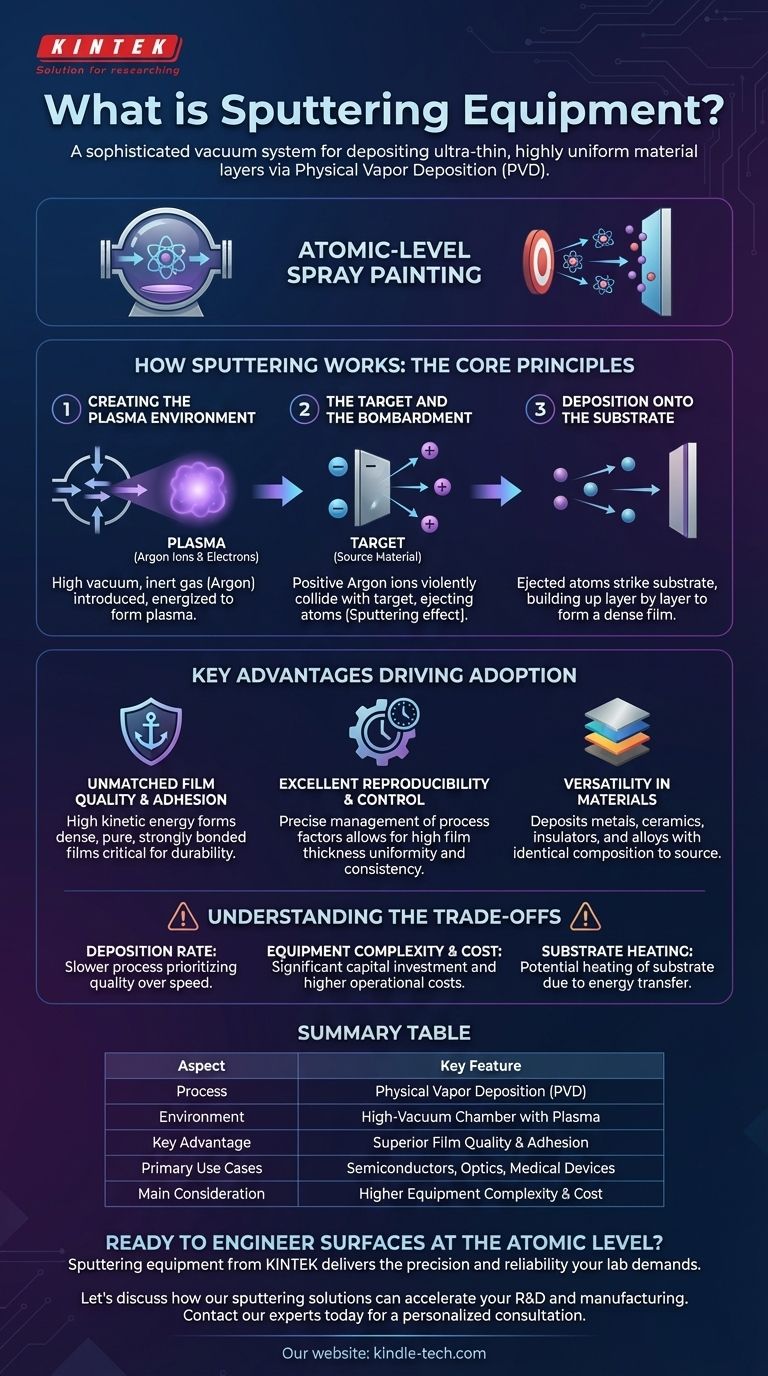

In essence, sputtering equipment is a sophisticated vacuum system designed to deposit ultra-thin, highly uniform layers of material onto a surface. It functions through a process called physical vapor deposition (PVD), where a high-energy plasma is used to bombard a source material (the "target"), ejecting individual atoms that then coat a desired object (the "substrate"). Think of it as a form of atomic-level spray painting, offering unparalleled precision and control.

Sputtering is not merely a coating technique; it is a foundational manufacturing process for creating high-performance materials. Its value lies in its ability to produce exceptionally dense, pure, and strongly bonded thin films, which is why it is indispensable in industries like semiconductors, optics, and medical devices.

How Sputtering Works: The Core Principles

To understand the equipment, you must first understand the process. The entire operation takes place inside a sealed vacuum chamber and relies on a few fundamental steps.

Creating the Plasma Environment

First, the chamber is pumped down to a high vacuum to remove any contaminants like air or water vapor. Then, an inert gas, most commonly Argon, is introduced at a very low pressure. Applying a high voltage creates an energized, glowing gas known as a plasma, which is a cloud of positive ions and free electrons.

The Target and the Bombardment

Inside the chamber is the target, a plate made of the material you wish to deposit. A negative voltage is applied to this target, causing the positive Argon ions from the plasma to accelerate and violently collide with its surface.

This high-energy bombardment physically knocks atoms loose from the target, ejecting them into the vacuum chamber. This is the core "sputtering" effect.

Deposition onto the Substrate

The ejected atoms travel in straight lines through the vacuum until they strike the substrate—the object being coated. Upon impact, these atoms condense and build up, layer by layer, to form an exceptionally thin and uniform film.

Key Advantages Driving Its Adoption

The physical nature of the sputtering process gives it distinct advantages that make it suitable for high-stakes, mass-production environments.

Unmatched Film Quality and Adhesion

Sputtered atoms arrive at the substrate with significant kinetic energy. This energy helps them form a very dense, uniform, and pure film with strong adhesion to the surface. This is critical for durable coatings that must not peel or flake.

Excellent Reproducibility and Control

The process is highly controllable. By precisely managing factors like gas pressure, voltage, and time, you can achieve excellent film thickness uniformity and high reproducibility from one run to the next. This reliability is why sputtering is compatible with mass production.

Versatility in Materials

Sputtering can deposit a vast range of materials, including metals, ceramics, and insulators. Crucially, it allows for alloy film deposition, where the composition of the sputtered film remains identical to the source alloy target.

Understanding the Trade-offs

No technology is perfect. While powerful, sputtering equipment comes with specific considerations that make it unsuitable for every application.

Deposition Rate

Compared to some other methods like thermal evaporation, sputtering can be a relatively slow process. The priority is film quality and control over raw deposition speed.

Equipment Complexity and Cost

Sputtering systems are complex machines requiring high-vacuum pumps, sophisticated power supplies, and process controls. This translates to a significant capital investment and higher operational costs.

Substrate Heating

The energy imparted by the bombarding plasma and the condensing atoms can heat the substrate. While often manageable, this can be a concern when coating temperature-sensitive materials like certain plastics or biological samples.

Making the Right Choice for Your Goal

Selecting a deposition technology depends entirely on your end goal. Sputtering excels where precision and film quality are paramount.

- If your primary focus is manufacturing high-performance electronics: Sputtering is the industry standard for creating the intricate, multi-layered structures found in microchips and sensors.

- If your primary focus is creating durable optical or protective coatings: The high adhesion and density of sputtered films make them ideal for anti-reflective coatings on lenses, hard coatings on tools, and biocompatible layers on medical implants.

- If your primary focus is rapid, low-cost bulk coating: You may want to evaluate faster, less complex methods like thermal evaporation, as sputtering’s main strengths are quality and control, not speed or low initial cost.

Ultimately, sputtering equipment is the definitive tool for engineering surfaces at the atomic level, enabling the creation of next-generation materials and devices.

Summary Table:

| Aspect | Key Feature |

|---|---|

| Process | Physical Vapor Deposition (PVD) |

| Environment | High-Vacuum Chamber with Plasma |

| Key Advantage | Superior Film Quality & Adhesion |

| Primary Use Cases | Semiconductors, Optics, Medical Devices |

| Main Consideration | Higher Equipment Complexity & Cost |

Ready to engineer surfaces at the atomic level?

Sputtering equipment from KINTEK delivers the precision and reliability your lab demands. Whether you are developing advanced semiconductors, durable optical coatings, or biocompatible medical devices, our expertise in lab equipment and consumables ensures you achieve exceptional film quality, uniformity, and adhesion.

Let's discuss how our sputtering solutions can accelerate your R&D and manufacturing. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- How do magnets enhance the sputtering rate in magnetron sputtering process and improve the thin film quality? Boost Deposition Speed & Film Quality

- What are the methods of oil sludge treatment? A Guide to Recovery, Disposal & Cost

- How does metal sputtering work? Achieve High-Purity, Uniform Thin Films

- How does temperature affect pyrolysis? Master Product Yields from Biochar to Syngas

- What is the function of KBr? A Key Tool for High-Quality FTIR Analysis of Solids

- What is sintered metal used for? From Auto Parts to Medical Implants

- How much pressure is required in DC sputtering? Optimize Your Thin-Film Deposition Process

- Is biochar production sustainable? Unlocking True Carbon Sequestration and Soil Health