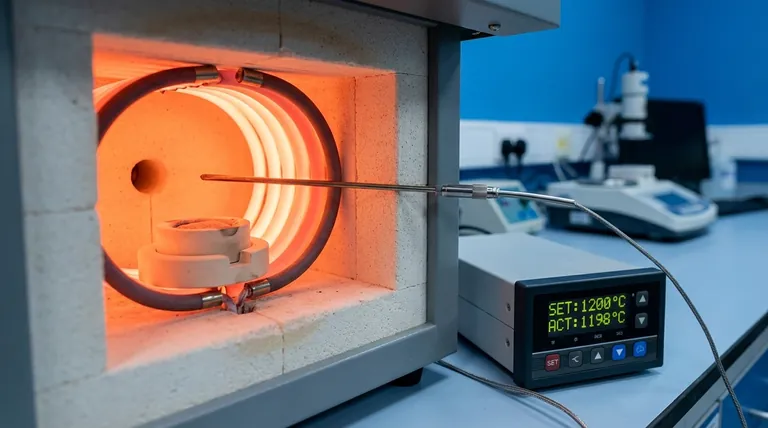

Temperature control in a resistance furnace is a closed-loop system designed to maintain a precise internal temperature. It works by continuously measuring the heat with a sensor, comparing it to a desired setpoint, and automatically adjusting the electrical power supplied to the heating elements to correct any deviation.

The core principle is not simply heating, but achieving thermal equilibrium. An effective control system uses a constant feedback loop—measuring, comparing, and adjusting—to hold a specific temperature with high precision, ensuring repeatable and reliable results for the material being processed.

The Core Components of Temperature Control

To understand the system, it's best to break it down into its three essential components, which work together in a continuous cycle.

The Sensor: The Thermocouple

A thermocouple acts as the "eyes" of the system. It is a temperature-sensing probe placed inside the furnace chamber that measures the current temperature.

The type and placement are critical. A control thermocouple provides the primary feedback for the system, while additional load thermocouples can be placed on or within the material to simulate its actual temperature.

The Brain: The Temperature Controller

The temperature controller is the decision-making hub. It receives the temperature reading from the thermocouple and compares it to the setpoint—the target temperature you have programmed.

Based on the difference between the actual temperature and the setpoint, the controller calculates the necessary power adjustment and sends a signal to the power supply.

The Muscle: The Heating Elements & Power Regulation

The heating elements are the components that convert electrical energy into heat through resistance (Joule heating). The controller adjusts the power delivered to these elements.

This regulation isn't just a simple on/off switch. It involves sophisticated methods to deliver just the right amount of energy.

How Power is Actually Adjusted

The controller must modulate the energy flow to the heating elements with precision. There are several ways this is accomplished.

Varying On/Off Time

This is the most common modern method. The controller rapidly switches the power to the elements on and off.

By varying the ratio of "on" time to "off" time over a very short cycle, it can deliver a precise average power, from 1% to 100%. This allows for very fine control of the heat output.

Varying Applied Voltage

In some systems, particularly larger furnaces, the controller can adjust the voltage supplied to the heating elements. Lowering the voltage reduces the heat output, and raising it increases it.

This can be done using devices like an auto-transformer, an induction regulator, or by changing the taps on a main transformer.

Beyond Simple Control: Ensuring Accuracy and Uniformity

Professional-grade temperature control is about more than just hitting a single number. It's about ensuring the entire furnace environment is accurate and consistent.

Control vs. Monitoring Locations

The control thermocouple drives the system, but it only represents one point in the furnace. For critical applications, additional thermocouples are used for monitoring.

These are placed in the hottest and coldest spots of the furnace, as identified by a Temperature Uniformity Survey (TUS), to ensure the entire working volume is within the specified tolerance.

System Accuracy Tests (SAT)

An SAT is a procedure to verify the accuracy of the entire temperature control system, from the thermocouple tip to the controller's display.

This test confirms that what the controller reads is what the furnace is actually experiencing, which is critical for compliance in industries like aerospace and medical device manufacturing.

Common Pitfalls to Avoid

Even with the right components, a poorly implemented system will produce poor results. Understanding the potential issues is key to achieving process control.

Thermocouple Placement is Critical

Placing the control thermocouple too close to a heating element or too far from the workload will give a false reading. The controller will maintain the setpoint at the sensor's location, but the material being heated could be significantly hotter or colder.

Temperature Overshoot and Lag

When a furnace is first heating up, a simple controller might keep the elements at 100% power until the setpoint is reached, causing the temperature to "overshoot" the target.

Modern controllers use sophisticated algorithms (like PID - Proportional, Integral, Derivative) to anticipate this, throttling back power as the temperature approaches the setpoint to prevent overshoot and undershoot.

The Gap Between Element and Load Temperature

The heating elements are always significantly hotter than the material they are heating. The control system must account for the time it takes for heat to transfer from the elements, through the furnace atmosphere, and into the product.

Making the Right Choice for Your Goal

The required level of control depends entirely on your process requirements.

- If your primary focus is high-precision processing (e.g., aerospace, medical): Your system must include multiple monitoring thermocouples, regular Temperature Uniformity Surveys, and documented System Accuracy Tests to guarantee compliance and quality.

- If your primary focus is general-purpose heating (e.g., simple lab work, hardening): A single, well-placed control thermocouple connected to a modern PID controller is often sufficient to achieve reliable results.

- If your primary focus is troubleshooting a furnace: Verify the entire feedback loop—confirm the thermocouple is properly calibrated and placed, the controller is tuned correctly, and the heating elements are functioning as expected.

Ultimately, mastering temperature control is about understanding that you are managing a dynamic system to achieve a stable and predictable thermal environment.

Summary Table:

| Component | Role | Key Function |

|---|---|---|

| Sensor (Thermocouple) | Measures Temperature | Provides real-time feedback from the furnace chamber |

| Controller | Decision-Making Hub | Compares actual temp to setpoint, adjusts power output |

| Heating Elements | Generate Heat | Convert electrical energy into controlled thermal energy |

| Power Regulation | Modulates Energy | Uses methods like on/off timing or voltage variation for precision |

Need precise temperature control for your lab processes? KINTEK specializes in high-performance lab equipment, including resistance furnaces with advanced temperature management systems. Whether you're in aerospace, medical device manufacturing, or general R&D, our solutions ensure accuracy, uniformity, and compliance. Contact us today to discuss your specific thermal processing needs and discover how KINTEK can enhance your lab's efficiency and reliability.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan