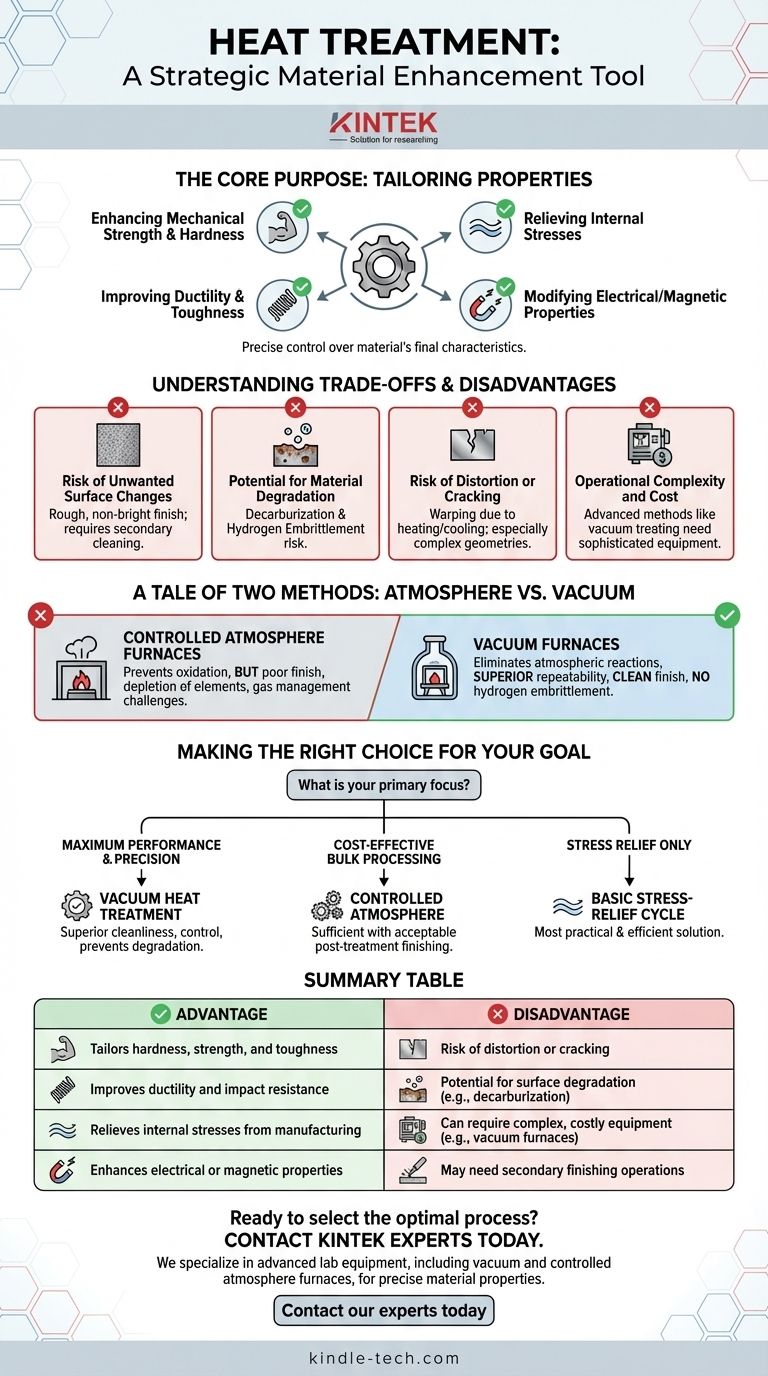

At its core, heat treatment is a highly controlled process used to fundamentally alter the physical and mechanical properties of a material, most commonly a metal like steel. The primary advantage is the ability to precisely tailor these properties—such as hardness, strength, and toughness—to meet specific engineering demands. However, these benefits come with disadvantages, including the risk of unwanted surface changes, material degradation, and distortion if the process is not managed correctly.

The central takeaway is that heat treatment is not a single process, but a category of techniques. Its "disadvantages" are often the specific trade-offs or limitations of a particular method, which can be mitigated by selecting a more advanced process like vacuum heat treatment.

The Core Purpose: Tailoring Material Properties

Heat treatment gives engineers precise control over a material's final characteristics after it has been formed or machined. This allows for an optimal balance of properties that are often mutually exclusive in a raw material.

Enhancing Mechanical Strength and Hardness

A primary goal is to increase a material's strength and its resistance to wear and abrasion. This is critical for components like gears, tools, and bearings that must withstand significant mechanical stress.

Improving Ductility and Toughness

Conversely, some heat treatment processes are designed to soften a material, reduce its brittleness, and increase its toughness. This makes the component less likely to fracture under sudden impact or load.

Relieving Internal Stresses

Manufacturing processes like welding, casting, or heavy machining introduce significant internal stresses into a part. A stress-relief heat treatment cycle can normalize the material, preventing future distortion and making it more stable for subsequent operations.

Modifying Other Key Properties

Beyond mechanical traits, heat treatment can be used to enhance a material's electrical conductivity or magnetic properties, which is essential for components used in motors and electronics.

Understanding the Trade-offs and Disadvantages

The potential downsides of heat treatment are almost always tied to the specific method being used and the level of control applied. Choosing the wrong process for a given material or goal can introduce new problems.

Risk of Unwanted Surface Changes

Traditional methods, such as controlled atmosphere heat treatment, can leave a workpiece with a rough, non-bright surface finish. This often requires secondary cleaning or finishing operations, adding time and cost.

Potential for Material Degradation

Improper atmospheric control can lead to the depletion of key elements from the material's surface, a process known as decarburization in steel. Certain processes also carry the risk of hydrogen embrittlement, which can make high-strength materials brittle and prone to failure.

Risk of Distortion or Cracking

The very nature of heating and cooling materials can cause them to warp, distort, or even crack. This risk is especially high for complex geometries or thin sections if heating and cooling rates are not managed with extreme precision.

Operational Complexity and Cost

Advanced heat treatment methods that mitigate the risks above, such as vacuum treating, require sophisticated and expensive equipment. The processes themselves can be complex, involving challenges with gas management or maintaining a hard vacuum.

A Tale of Two Methods: Atmosphere vs. Vacuum

The evolution from atmosphere-based to vacuum-based heat treatment clearly illustrates the trade-offs.

Controlled Atmosphere Furnaces

This common method uses a controlled gas environment to prevent oxidation. However, as noted, it can result in poor surface finish, deplete surface elements, and presents challenges in managing and recovering the process gases.

Vacuum Furnaces

By performing the process in a vacuum, this method eliminates reactions with atmospheric gases entirely. This provides superior repeatability and a clean surface finish. It also completely avoids the risk of hydrogen embrittlement, making it a safer and more reliable choice for critical components.

Making the Right Choice for Your Goal

Selecting the appropriate heat treatment method requires balancing the desired outcome with the acceptable trade-offs in cost, complexity, and final finish.

- If your primary focus is maximum performance and precision: A process like vacuum heat treatment is the superior choice for its cleanliness, control, and ability to prevent material degradation.

- If your primary focus is cost-effective bulk processing: A controlled atmosphere process may be sufficient, provided that some post-treatment surface finishing is acceptable.

- If your primary focus is simply relieving stress after fabrication: A basic stress-relief cycle, which is less complex than hardening or tempering, is often the most practical and efficient solution.

Ultimately, viewing heat treatment as a strategic tool for material enhancement allows you to select the right process that maximizes advantages while minimizing inherent risks.

Summary Table:

| Advantage | Disadvantage |

|---|---|

| Tailors hardness, strength, and toughness | Risk of distortion or cracking |

| Improves ductility and impact resistance | Potential for surface degradation (e.g., decarburization) |

| Relieves internal stresses from manufacturing | Can require complex, costly equipment (e.g., vacuum furnaces) |

| Enhances electrical or magnetic properties | May need secondary finishing operations |

Ready to select the optimal heat treatment process for your materials?

At KINTEK, we specialize in providing advanced lab equipment, including vacuum and controlled atmosphere furnaces, to help you achieve precise material properties while minimizing risks like distortion and surface degradation. Our expertise ensures you get the right balance of performance, cost, and finish for your specific application.

Contact our experts today to discuss your laboratory's heat treatment needs and discover how our solutions can enhance your results.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost