At its core, hot press forming offers a decisive advantage by combining controlled heat and pressure to create strong, complex, and lightweight parts that are often impossible to produce with traditional cold forming methods. This process reshapes materials at a microstructural level, resulting in superior final properties and greater design freedom.

The fundamental advantage of hot press forming is not just about shaping a material, but about fundamentally improving it. By applying heat, the process reduces the force needed for forming while simultaneously enhancing the material's internal structure, leading to stronger, denser, and more intricate components.

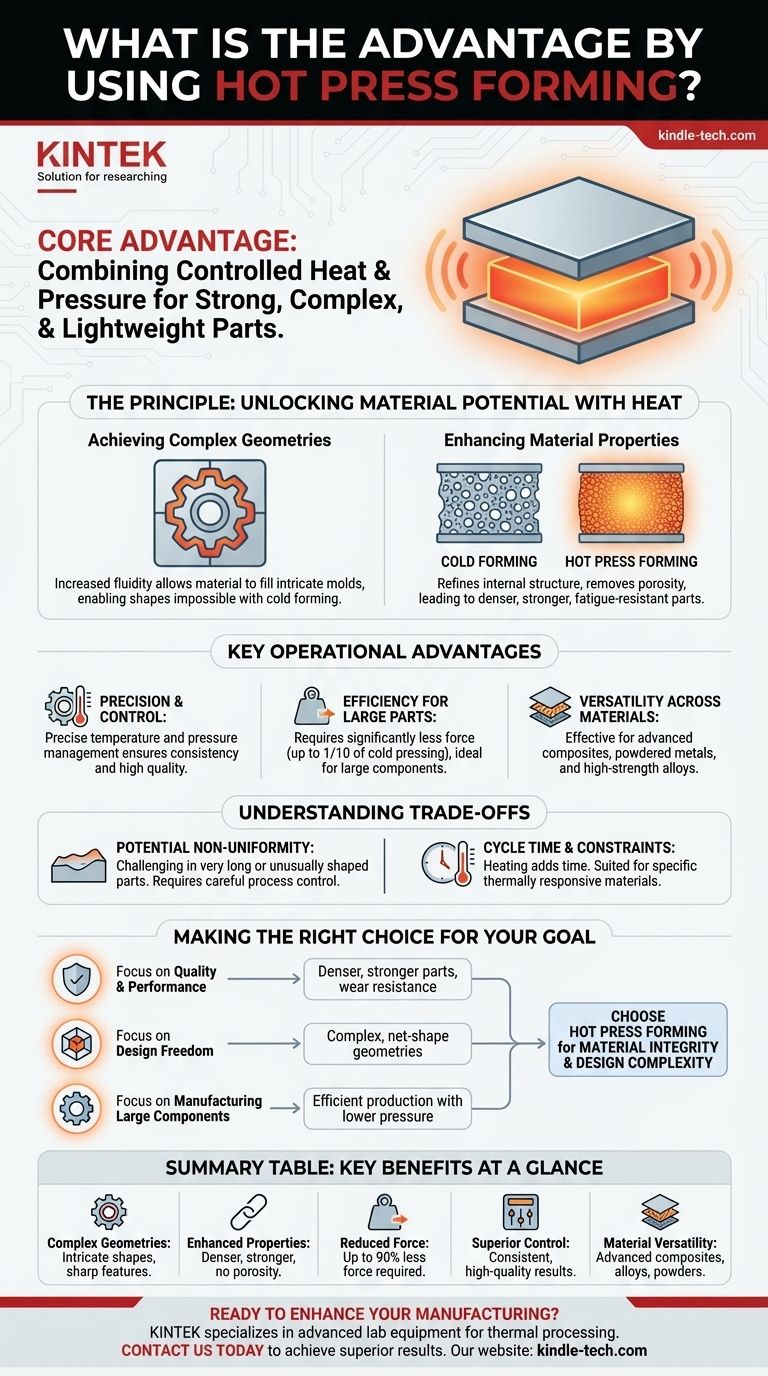

The Principle: Unlocking Material Potential with Heat

The unique benefits of hot press forming stem from its use of thermal energy to make materials more malleable before and during the application of pressure. This simple combination fundamentally changes what is possible in manufacturing.

Achieving Complex Geometries

By heating the material, typically a metal alloy or powdered composite, its formability increases dramatically. The material flows more easily under pressure, almost like a thick liquid.

This increased fluidity allows the material to fill every detail of a complex mold. This makes it possible to produce intricate shapes and sharp features that would cause a cold material to crack or fail.

Enhancing Material Properties

The combination of heat and pressure does more than just shape the part; it refines its internal structure. The process can effectively remove internal porosities or voids within the material.

This results in a final part that is denser, stronger, and more resistant to fatigue, wear, and heat. The process creates powerful mechanical and electrical connections at a microscopic level, leading to superior performance in demanding environments.

Key Operational Advantages

Beyond the final product's quality, the hot pressing process itself offers significant efficiencies and control compared to other methods.

Precision and Process Control

Modern hot press machines offer extremely precise temperature and pressure control. The ability to manage heating rates and apply pressure evenly is critical for consistency.

Many systems can be managed with advanced controls, allowing for pre-programmed cycles tailored to specific materials and part geometries, ensuring repeatability and high quality.

Efficiency for Large or Demanding Parts

Hot forming requires significantly less pressing force—sometimes as little as one-tenth of that needed for cold pressing.

This reduction in required pressure means that larger parts can be produced on smaller, less energy-intensive equipment. This leads to reduced equipment investment and lower energy consumption for certain applications.

Versatility Across Materials

The process is highly adaptable and is used across numerous industries. It is not limited to a single material type.

Hot pressing is integral for working with advanced composites, powdered metals, and high-strength steel alloys that are difficult or impossible to shape when cold.

Understanding the Trade-offs

No process is without its limitations. An objective assessment requires understanding where hot press forming may present challenges.

Potential for Non-Uniformity

While the process aims for evenness, achieving perfectly uniform density and properties can be challenging, especially in very long or unusually shaped parts.

Careful process control and tool design are required to mitigate these risks and ensure consistent quality throughout the entire component.

Cycle Time and Material Constraints

Heating the material and tools before forming adds time to the production cycle compared to instantaneous cold stamping.

Additionally, the process is best suited for materials that respond well to thermal treatment. The specific material choice is critical and can be more limited than with other forming techniques.

Making the Right Choice for Your Goal

Selecting hot press forming depends entirely on your project's primary objective.

- If your primary focus is part quality and performance: The key advantage is the ability to create denser, stronger parts with superior resistance to wear and fatigue by eliminating internal porosity.

- If your primary focus is design freedom: This process excels at producing complex, net-shape geometries that cannot be achieved through cold forming or machining alone.

- If your primary focus is manufacturing large components: The significantly lower pressure requirements can make hot pressing a more efficient and cost-effective method for producing large-scale parts.

Ultimately, choosing hot press forming is a strategic decision to prioritize material integrity and design complexity over raw production speed.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Complex Geometries | Produces intricate shapes and sharp features impossible with cold forming. |

| Enhanced Material Properties | Creates denser, stronger parts by eliminating internal porosity. |

| Reduced Pressing Force | Requires up to 90% less force than cold pressing, ideal for large parts. |

| Superior Process Control | Precise temperature and pressure management ensures consistent, high-quality results. |

| Material Versatility | Effective for advanced composites, powdered metals, and high-strength alloys. |

Ready to enhance your manufacturing process with the advantages of hot press forming?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including solutions for thermal processing and material testing. Whether you are developing new materials or optimizing production for stronger, more complex parts, our expertise can help you achieve superior results.

Contact us today to discuss how our equipment and support can bring the benefits of controlled heat and pressure to your laboratory or production line.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does high-precision pressure control of a vacuum hot press furnace influence graphite/copper composites?

- What are the advantages of using a vacuum hot press for ZnS ceramics? Efficiency and Optical Performance Explored

- What is the application value of a vacuum hot press furnace? Unlock High-Density Complex Carbide Ceramics

- What is the difference between conventional and spark sintering? Choose the Right Process for Your Materials

- What is the sintering pressing force? A Guide to Achieving Maximum Part Density

- What is the role of a vacuum hot-pressing furnace in Fe-Cu-Ni-Sn-VN sintering? Boost Density & Wear Resistance

- How hot isostatic pressing works? Achieve 100% Density in Your High-Performance Components

- How does a vacuum hot pressing sintering furnace facilitate TiBw/TA15 synthesis? Achieve 100% Dense Titanium Composites