The primary advantage of Potassium Bromide (KBr) is its exceptional optical transparency across a very broad range of the infrared (IR) spectrum. This unique property makes it a nearly "invisible" medium for holding samples during spectroscopic analysis, ensuring that the instrument measures the sample itself and not the material containing it. For this reason, it has become the gold-standard material for creating sample pellets and windows in IR and FTIR spectroscopy.

While many materials exist for spectroscopic analysis, KBr offers an unparalleled combination of wide-range infrared transparency and cost-effectiveness. Its primary trade-off, a sensitivity to moisture, is a manageable factor that must be understood to achieve accurate results.

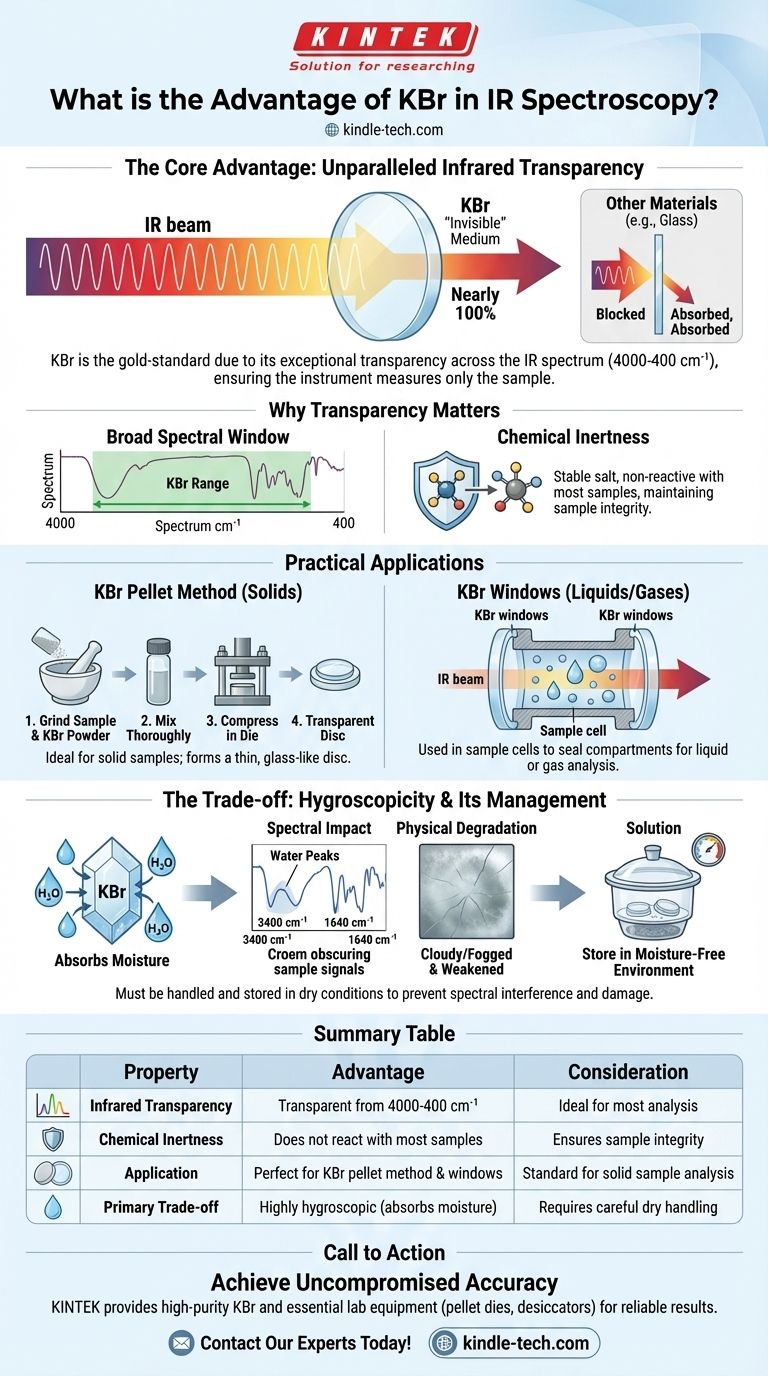

The Core Advantage: Unparalleled Infrared Transparency

Why Transparency Matters in IR Spectroscopy

The goal of infrared spectroscopy is to measure how a sample's molecules absorb specific frequencies of IR light. This absorption pattern acts as a chemical "fingerprint."

To get an accurate fingerprint, the material holding the sample—whether it's a window or a pressed pellet—must not absorb IR light in the same region. KBr is ideal because it allows the IR beam to pass through almost entirely unaffected.

A Broad and Consistent Spectral Window

KBr is transparent across the entire mid-infrared region, typically from 4000 cm⁻¹ down to 400 cm⁻¹. This covers the full range of interest for most organic and inorganic molecular analysis.

By contrast, materials like glass or quartz are opaque to most of this range, making them useless for this type of spectroscopy.

Chemical Inertness

Potassium Bromide is a stable salt that does not react with the vast majority of chemical samples. This inertness is crucial because it prevents the KBr matrix from altering the sample or creating new, interfering signals in the spectrum.

Practical Applications in the Laboratory

The KBr Pellet Method for Solid Samples

For solid samples that are not soluble or are difficult to analyze otherwise, the KBr pellet technique is standard practice.

The solid sample is ground into an extremely fine powder, thoroughly mixed with dry, high-purity KBr powder, and then compressed under immense pressure in a die. This process forms a thin, transparent, glass-like disk that can be placed directly in the spectrometer's beam path.

KBr Windows for Sample Cells

KBr can also be grown into large, single crystals and cut and polished into circular or rectangular windows.

These windows are used to construct sample cells for analyzing liquids or gases. They seal the sample compartment while allowing the IR beam to pass through, interact with the sample, and reach the detector.

Understanding the Trade-offs: The Challenge of Hygroscopicity

What is Hygroscopicity?

The single most significant disadvantage of KBr is that it is hygroscopic, meaning it readily absorbs moisture from the ambient air.

This property is the source of nearly all problems encountered when working with KBr optics or pellets.

The Impact on Spectral Quality

Water (H₂O) has very strong, broad absorption bands in the infrared spectrum, particularly around 3400 cm⁻¹ (O-H stretching) and 1640 cm⁻¹ (H-O-H bending).

If KBr absorbs moisture, these water peaks will appear in your spectrum, potentially overlapping with and obscuring important signals from your actual sample. This is a common source of error and misinterpretation.

The Physical Consequences

Over time, moisture absorption will physically degrade KBr optics. Windows will become cloudy or "fogged," scattering the IR beam and reducing the signal quality. In severe cases, the absorbed water can cause the crystal structure to weaken, leading to cracks or fractures.

For this reason, all KBr materials must be stored in a moisture-free environment, such as a desiccator or a drying oven at a low temperature.

Making the Right Choice for Your Goal

The decision to use KBr depends entirely on your sample and analytical needs.

- If your primary focus is routine, cost-effective analysis of dry solid samples: KBr pellets are the industry standard and an excellent choice, provided you adhere to proper dry handling and storage procedures.

- If your primary focus is analyzing aqueous (water-based) solutions: KBr is completely unsuitable as it will dissolve. You must use water-insoluble materials like Zinc Selenide (ZnSe), Silver Chloride (AgCl), or Diamond (for ATR).

- If your primary focus is high-throughput work or analyzing abrasive samples: The softness of KBr can be a liability. More durable but expensive materials used in ATR-FTIR, such as ZnSe or Diamond, are often a better long-term investment.

Understanding these properties allows you to leverage KBr's optical clarity while mitigating its primary weakness, ensuring reliable and accurate spectroscopic results.

Summary Table:

| Property | Advantage | Consideration |

|---|---|---|

| Infrared Transparency | Transparent from 4000 to 400 cm⁻¹ | Ideal for most organic/inorganic analysis |

| Chemical Inertness | Does not react with most samples | Ensures sample integrity |

| Application | Perfect for KBr pellet method & windows | Standard for solid sample analysis |

| Primary Trade-off | Highly hygroscopic (absorbs moisture) | Requires careful dry handling and storage |

Achieve Uncompromised Accuracy in Your IR Analysis

KBr's unparalleled transparency is key to reliable spectroscopy, but proper handling is crucial. KINTEK specializes in providing high-purity KBr and the essential lab equipment—like pellet dies and desiccators—you need to mitigate moisture issues and ensure perfect results every time.

Whether you're setting up a new lab or optimizing your current FTIR processes, our experts are here to help you select the right materials and tools for your specific applications.

Contact our spectroscopy specialists today to discuss your lab's needs and ensure your analyses are never compromised by material limitations.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Is KBr used in IR spectroscopy? The Essential Guide to Solid Sample Analysis

- How does a manual press work? Unlock Powerful Force Without Electricity

- What are the different types of mechanical presses? Choose the Right Press for Your Application

- What are the industrial applications of plate and frame filter press? A Guide to Efficient Solid-Liquid Separation

- What is the function of a laboratory hydraulic press in W-Cu composites? Control Porosity and Material Ratio

- What is the pellet technique used in IR for? Creating Clear, Transparent Samples for Accurate Analysis

- What function does a laboratory hydraulic press serve in photocatalytic pigments? | Enhance Sample Standardization

- What is the pressure for pellet press? Achieve Perfect Pellet Compaction Every Time