The definitive advantage of Low-Pressure Chemical Vapor Deposition (LPCVD) over Atmospheric Pressure (APCVD) is its ability to produce films of exceptionally high uniformity and conformality. By operating in a vacuum, LPCVD ensures that reactant gases can evenly coat complex, three-dimensional micro-structures and large batches of substrates, a feat that is challenging at atmospheric pressure.

The core trade-off is simple: LPCVD prioritizes film quality, uniformity, and purity by reducing pressure, while APCVD prioritizes a high deposition rate. The choice between them depends entirely on whether the application demands precision or speed.

The Critical Role of Pressure in Deposition

To understand the advantages of LPCVD, we must first look at the behavior of gases. The operating pressure fundamentally changes how reactant molecules travel and interact with a substrate surface.

The Impact of Molecular Travel (Mean Free Path)

At atmospheric pressure (APCVD), the chamber is dense with gas molecules. This results in a very short mean free path, meaning reactant molecules collide frequently with each other and travel in a chaotic, diffusion-like pattern.

In contrast, under the vacuum conditions of LPCVD, the chamber has far fewer molecules. This creates a long mean free path, allowing reactant molecules to travel much farther in straight lines before colliding.

Mass Transport vs. Surface Reaction Limits

This difference in mean free path dictates what limits the deposition process.

APCVD is typically a mass-transport limited process. The reaction is limited by the rate at which fresh reactant molecules can diffuse through the dense gas to reach the substrate. This often leads to reactant depletion as the gas flows across the surface.

LPCVD is a surface-reaction-rate limited process. Because reactants can easily reach the entire surface, the deposition speed is limited only by the rate of the chemical reaction on the substrate itself, which is primarily controlled by temperature.

Key Advantages of Operating at Low Pressure (LPCVD)

The shift to a surface-reaction-rate limited process gives LPCVD several distinct and powerful advantages, particularly for fabricating microelectronics.

Superior Film Uniformity

Because reactants are not depleted as they flow across the substrate, every part of the surface is exposed to a near-identical concentration of gas. This results in a film that is highly uniform in thickness across the entire wafer.

This uniformity also allows for batch processing, where dozens or even hundreds of wafers can be stacked vertically in a furnace tube, dramatically increasing throughput despite a lower per-wafer deposition rate.

Excellent Conformality

Conformality is the ability of a film to coat a complex, non-flat surface evenly. The long mean free path in LPCVD allows reactant gases to penetrate deep into microscopic trenches and holes before reacting.

The result is a film that perfectly conforms to the underlying topography, which is absolutely critical for building the multi-layered structures found in integrated circuits and MEMS devices.

Higher Film Purity and Quality

Operating in a vacuum inherently reduces the concentration of background contaminants like oxygen, water, or nitrogen that could be unintentionally incorporated into the growing film.

Furthermore, the typically slower, more controlled growth in an LPCVD process often results in films with better crystal structure, higher density, and lower residual stress.

Understanding the Trade-offs: The Case for APCVD

While LPCVD excels in precision, it is not the ideal solution for every application. APCVD holds a key advantage that makes it the preferred choice in certain scenarios.

The Decisive Advantage of Speed

The primary strength of APCVD is its high deposition rate. The much higher concentration of reactant molecules at atmospheric pressure leads to significantly faster film growth.

This makes APCVD highly effective for applications where thick layers are needed and perfect uniformity is not the primary concern, such as depositing protective coatings or thick oxide layers on solar cells.

Simpler Equipment Requirements

APCVD systems do not require the expensive and complex high-vacuum pumps and associated hardware needed for LPCVD. For applications where a vacuum environment is not necessary, this can lead to a simpler and more cost-effective equipment setup.

Making the Right Choice for Your Goal

The decision between LPCVD and APCVD is a strategic engineering choice based on the specific requirements of the final product.

- If your primary focus is fabricating complex microelectronics (e.g., integrated circuits, MEMS): LPCVD is the clear choice for its unparalleled uniformity and conformality over intricate topographies.

- If your primary focus is applying thick, functional coatings rapidly (e.g., for solar cells or tooling): APCVD's high deposition rate provides a significant advantage in throughput and cost-effectiveness.

- If your primary focus is achieving the highest possible film purity and density: LPCVD's vacuum environment and controlled reaction kinetics give it a distinct edge.

Ultimately, choosing your deposition method is a direct reflection of whether your priority lies in the absolute precision of the film or the sheer speed of its creation.

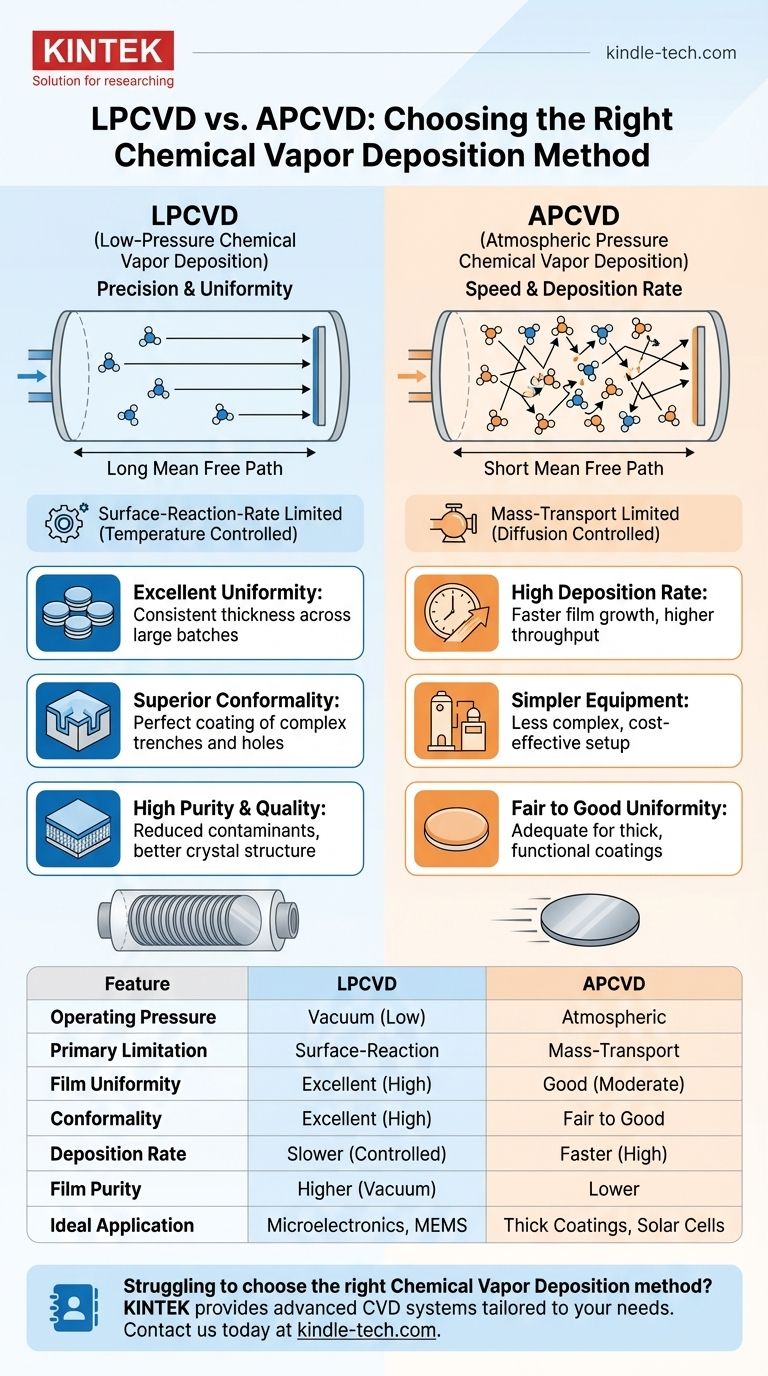

Summary Table:

| Feature | LPCVD | APCVD |

|---|---|---|

| Operating Pressure | Vacuum (Low Pressure) | Atmospheric Pressure |

| Primary Limitation | Surface-Reaction-Rate Limited | Mass-Transport Limited |

| Film Uniformity | Excellent (High) | Good (Moderate) |

| Conformality | Excellent (High) | Fair to Good |

| Deposition Rate | Slower (Controlled) | Faster (High) |

| Film Purity | Higher (Vacuum Environment) | Lower |

| Ideal Application | Microelectronics, MEMS, Precision Coatings | Thick Coatings, Solar Cells, Rapid Deposition |

Struggling to choose the right Chemical Vapor Deposition method for your application?

KINTEK specializes in providing high-quality lab equipment and consumables, including advanced CVD systems tailored to your specific research and production needs. Whether you require the precision of LPCVD for microelectronics or the speed of APCVD for thick coatings, our experts can help you select the ideal solution to enhance your lab's efficiency and results.

Contact us today via our contact form to discuss your project requirements and discover how KINTEK can support your laboratory's success with reliable, performance-driven equipment.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition