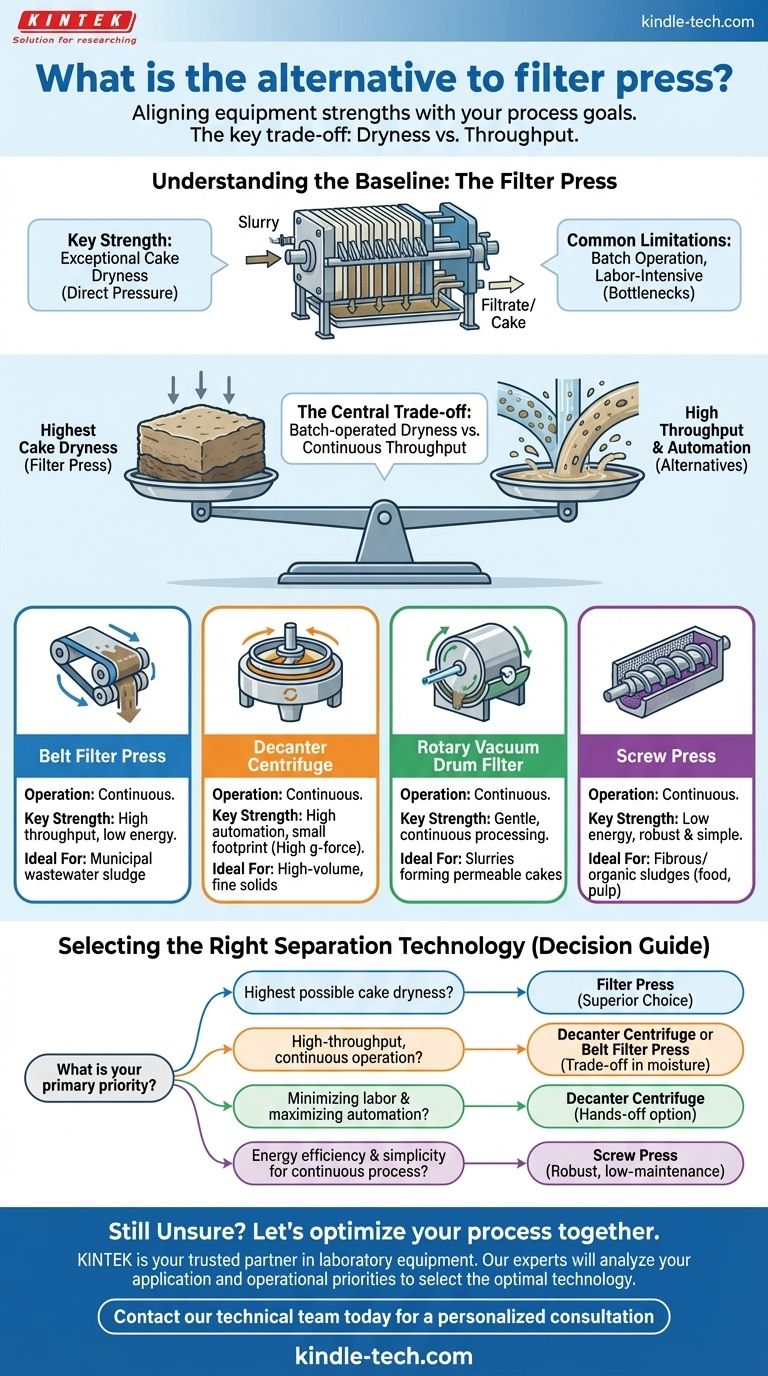

While the filter press is a powerful and highly adaptable tool, several key alternatives exist for industrial solid-liquid separation. The most common alternatives are the belt filter press, the decanter centrifuge, the rotary vacuum drum filter, and the screw press. Each of these technologies offers a different balance of throughput, automation, and final product characteristics.

The choice of an alternative to a filter press is not about finding a universally "better" technology, but about aligning the equipment's core strengths with your specific process goals. The central trade-off is often between the exceptional cake dryness of a batch-operated filter press and the high-throughput, continuous operation of its alternatives.

Understanding the Baseline: The Filter Press

To evaluate alternatives, we must first establish the benchmark. The filter press is widely used for its reliability and effectiveness in producing a very dry solid cake and clear liquid filtrate.

How It Works

A filter press operates as a batch process. It pumps a slurry under high pressure into a series of chambers lined with filter cloths. The liquid (filtrate) passes through the cloth, while the solids (cake) are trapped inside, forming dense, dry slabs.

Key Strengths

The primary advantage of a filter press is its ability to achieve exceptionally high cake dryness. Because it relies on direct pressure, it can dewater slurries more effectively than many other mechanical methods. It is also highly versatile across many industries.

Common Limitations

The main drawback is its batch operation, which can create bottlenecks in a continuous process. Manual or semi-automatic presses can also be labor-intensive, requiring operators to empty the solid cakes at the end of each cycle, increasing operational costs.

Key Alternatives to the Filter Press

Each alternative addresses one or more of the filter press's limitations, typically by offering a continuous, more automated process, though often with a trade-off in cake dryness.

Belt Filter Press

A belt filter press dewaters slurry continuously by passing it between two tensioned, porous belts. These belts guide the slurry through a series of rollers that gradually increase pressure, squeezing the liquid out.

This method is well-suited for high-volume, flocculated sludges, such as those found in municipal wastewater treatment. It offers high throughput with lower energy consumption than a centrifuge.

Decanter Centrifuge

A decanter centrifuge uses extremely high rotational speed to create immense g-forces (often thousands of times the force of gravity). This force separates the denser solids from the liquid in a continuous flow.

Centrifuges excel in applications requiring very high throughput and a high degree of automation. They have a small footprint for their capacity and can handle a wide range of particle sizes, including very fine solids.

Rotary Vacuum Drum Filter

This technology involves a continuously rotating drum covered with a filter cloth that is partially submerged in a trough of slurry. A vacuum applied to the inside of the drum pulls the liquid through the cloth, leaving a thin layer of cake on the drum's surface.

A blade then scrapes the dried cake off the drum as it rotates. This method is effective for slurries that form a permeable cake and require continuous, gentle processing.

Screw Press

A screw press operates by conveying material with a slow-rotating helical screw through a tapered channel lined with a screen. The decreasing volume compresses the material, forcing the liquid out through the screen.

Screw presses are known for their simplicity, low energy consumption, and robust operation. They are ideal for materials with high fiber content, like food processing waste or paper pulp sludges, and offer continuous, low-maintenance operation.

Understanding the Trade-offs

Choosing the right technology requires an objective comparison of their core performance characteristics.

Cake Dryness vs. Throughput

This is the most critical trade-off. A filter press provides the highest cake dryness but is limited by its batch cycle time.

Conversely, centrifuges and belt presses offer massive, continuous throughput but typically produce a cake with higher moisture content. For applications where disposal costs are tied to weight, the extra dryness from a filter press can be decisive.

Automation and Labor Costs

A manual filter press has high operational costs due to the labor required to manage each batch cycle. In contrast, a decanter centrifuge is almost fully automated, significantly reducing labor requirements and making it ideal for 24/7 operations. Belt and screw presses also offer continuous, low-touch operation.

Capital Cost vs. Operating Cost

Filter presses often have a lower initial capital cost compared to a high-performance centrifuge of similar capacity. However, the high labor and potential downtime associated with a manual filter press can lead to higher long-term operating costs.

Feed Sensitivity

Filter presses are generally quite adaptable to variations in feed consistency and solid content. Some continuous systems, particularly centrifuges, may require more careful control of the feed slurry and polymer conditioning to operate at peak efficiency.

Selecting the Right Separation Technology

Your choice must be driven by your most important operational priority.

- If your primary focus is achieving the highest possible cake dryness: The traditional chamber or membrane filter press remains the superior choice, despite its batch nature.

- If your primary focus is high-throughput, continuous operation: A decanter centrifuge or belt filter press is the best alternative, accepting a trade-off in cake moisture.

- If your primary focus is minimizing labor and maximizing automation: A decanter centrifuge is the leading option for a hands-off, continuous process.

- If your primary focus is energy efficiency and simplicity for a continuous process: A screw press offers a robust, low-maintenance solution, particularly for fibrous or organic sludges.

Ultimately, the best alternative is the one that aligns perfectly with your specific operational priorities, from disposal costs to labor availability.

Summary Table:

| Alternative Technology | Operation Type | Key Strength | Ideal For |

|---|---|---|---|

| Belt Filter Press | Continuous | High throughput, low energy | Municipal wastewater sludge |

| Decanter Centrifuge | Continuous | High automation, small footprint | High-volume, fine solids |

| Rotary Vacuum Drum Filter | Continuous | Gentle, continuous processing | Slurries forming permeable cakes |

| Screw Press | Continuous | Low energy, robust & simple | Fibrous/organic sludges (e.g., food, pulp) |

Still Unsure Which Solid-Liquid Separation Technology is Right for Your Lab?

Choosing between a filter press and its alternatives depends entirely on your specific process goals: maximum cake dryness, high-throughput automation, or energy efficiency. KINTEK, your trusted partner in laboratory equipment, can help you navigate these critical trade-offs.

We specialize in providing robust and efficient lab equipment and consumables to meet your exact dewatering and separation needs. Our experts will work with you to analyze your application, from slurry characteristics to operational priorities, ensuring you select the optimal technology to enhance your lab's productivity and reduce costs.

Let's optimize your process together. Contact our technical team today for a personalized consultation.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Vacuum Freeze Dryer

- Automatic Laboratory Heat Press Machine

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- Can autoclave sterilize liquid? Master Safe and Effective Liquid Sterilization

- What is a lab autoclave? Your Guide to Sterilization with Pressurized Steam

- What is the use of autoclave in medical? The Critical Role of Sterilization in Patient Safety

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- What temperature must be reached for sterilization in 10-12 minutes? Achieve Rapid, Reliable Sterility with Flash Autoclaving