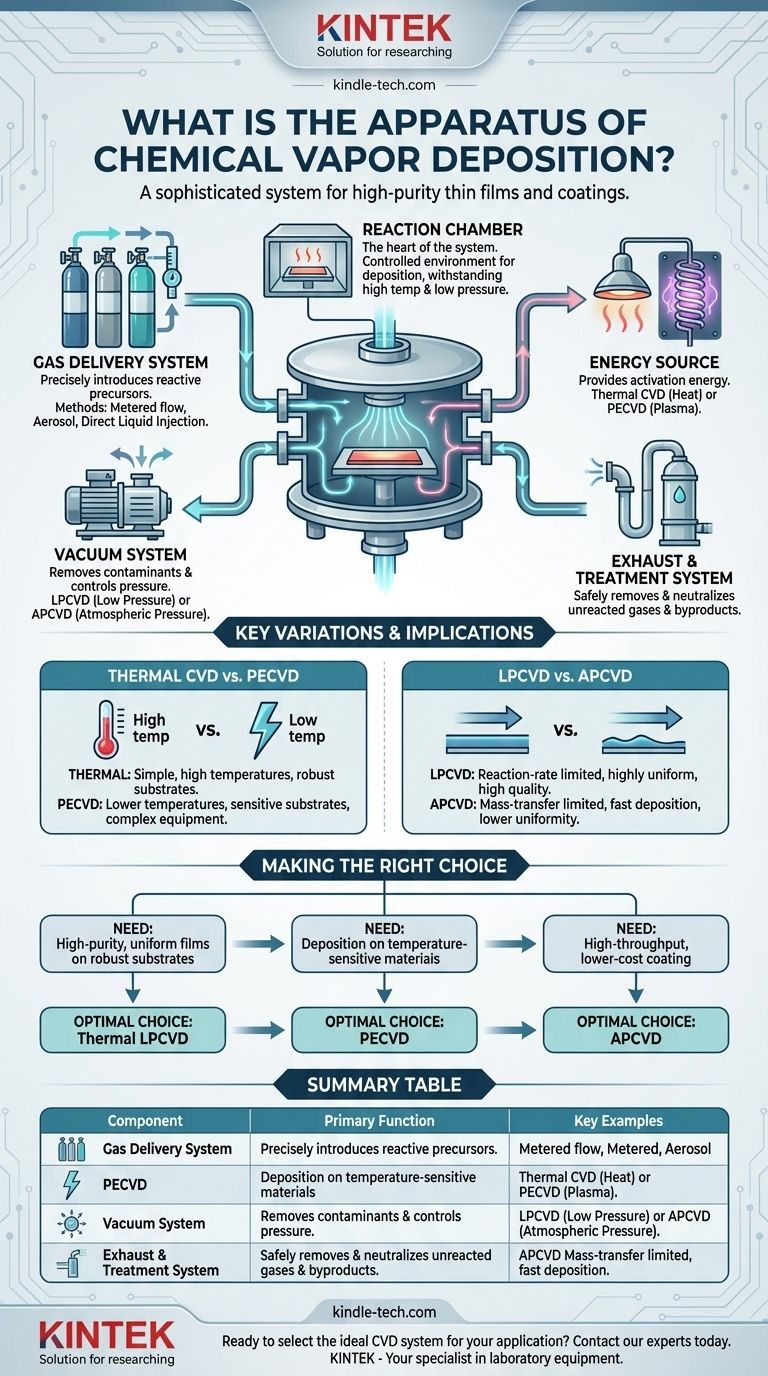

At its core, a chemical vapor deposition (CVD) apparatus is a sophisticated system designed to create high-purity, high-performance thin films and coatings. The typical equipment consists of a gas delivery system to introduce reactive chemicals, a reaction chamber where the process occurs, an energy source to initiate the reaction, a vacuum system to control the environment, and an exhaust system to safely remove byproducts.

A CVD system isn't just a collection of parts; it's a precisely engineered environment designed to transport reactive chemicals (precursors) to a surface, supply the energy needed for a chemical reaction, and safely remove the waste.

The Anatomy of a CVD System

Each component of a CVD apparatus serves a critical function in controlling the deposition of a thin film. Understanding the role of each part is key to understanding the process itself.

The Gas and Precursor Delivery System

This system is responsible for precisely introducing the reactive precursor materials into the reaction chamber. The precursors are the chemical building blocks of the final film.

The delivery method can vary. In many cases, it involves a metered flow of gas, but some systems use an aerosol-assisted method or direct liquid injection to vaporize a liquid precursor before it enters the chamber.

The Reaction Chamber (or Reactor)

This is the heart of the system where the substrate (the material to be coated) is placed. It is an enclosed, controlled environment, often a vacuum chamber, designed to contain the chemical reaction.

The chamber must be able to withstand the required process conditions, which can include high temperatures, low pressures, and corrosive chemical environments.

The Energy Source

The energy source provides the activation energy needed to break down the precursor molecules and drive the chemical reaction on the substrate's surface. The type of energy source is a primary way to classify different CVD methods.

Thermal CVD uses heat, directly warming the substrate to initiate the reaction. In contrast, plasma-enhanced CVD (PECVD) uses an electric field to generate a plasma (an ionized gas), which provides the energy to drive the reaction at much lower temperatures.

The Vacuum System

The vacuum system, typically a series of pumps, serves two main purposes. First, it removes atmospheric gases and contaminants from the reaction chamber to ensure film purity.

Second, it allows for precise control over the chamber's pressure. The process can be run at atmospheric pressure (APCVD) or at very low pressure (LPCVD), which dramatically affects the deposition process.

The Exhaust and Treatment System

After the reaction, any unreacted precursor gases and gaseous byproducts must be safely removed from the chamber.

The exhaust system directs these gases to a treatment system (often called a scrubber) that neutralizes any hazardous or toxic materials before they are released into the atmosphere.

Understanding Key Variations and Their Implications

The specific configuration of the CVD apparatus depends on the desired outcome. The choices made in the system's design create important trade-offs in performance, cost, and applicability.

Thermal CVD vs. Plasma-Enhanced CVD (PECVD)

The most significant distinction is often the energy source. Thermal CVD is relatively simple but requires very high temperatures, which can damage sensitive substrates like polymers or complex electronic devices.

PECVD allows for deposition at significantly lower temperatures. This makes it ideal for temperature-sensitive materials, but the equipment is more complex and the plasma itself can sometimes introduce stress or damage into the deposited film.

Low-Pressure (LPCVD) vs. Atmospheric-Pressure (APCVD)

Operating pressure fundamentally changes how the film grows. In LPCVD, the process is reaction-rate limited. This means the deposition is controlled by the speed of the chemical reaction on the surface, which typically results in highly uniform, high-quality films that conform well to complex shapes.

In APCVD, the process is mass-transfer limited. The deposition rate is determined by how fast the precursor gas can travel to the substrate. This allows for much faster deposition rates but often results in lower film uniformity and purity.

Making the Right Choice for Your Goal

The optimal CVD apparatus is determined entirely by the application's specific requirements for film quality, material compatibility, and production speed.

- If your primary focus is high-purity, uniform films on robust substrates: Thermal LPCVD is often the standard due to its excellent control and resulting film quality.

- If your primary focus is depositing on temperature-sensitive materials (like polymers or electronics): PECVD is necessary because it allows for deposition at much lower temperatures.

- If your primary focus is high-throughput, lower-cost coating: APCVD can be an effective choice, though often with a trade-off in film uniformity.

Understanding these core components and their interplay empowers you to select and optimize the ideal deposition process for your specific material and application.

Summary Table:

| CVD System Component | Primary Function | Key Examples |

|---|---|---|

| Gas Delivery System | Precisely introduces reactive precursor chemicals. | Gas flow meters, bubblers, direct liquid injection. |

| Reaction Chamber | Enclosed environment where the substrate is coated. | Hot-wall reactors, cold-wall reactors. |

| Energy Source | Provides activation energy for the chemical reaction. | Heaters (Thermal CVD), Plasma (PECVD). |

| Vacuum System | Controls chamber pressure and removes contaminants. | Pumps for LPCVD (Low Pressure). |

| Exhaust System | Safely removes and treats process byproducts. | Scrubbers, abatement systems. |

Ready to select the ideal CVD system for your application?

Whether you need the high uniformity of Thermal LPCVD for robust substrates or the low-temperature capability of PECVD for sensitive materials, KINTEK has the expertise and equipment to meet your lab's thin film deposition needs.

Contact our experts today to discuss your specific requirements for film quality, material compatibility, and throughput. Let KINTEK, your specialist in laboratory equipment, help you optimize your deposition process.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What happens at deposition of atoms on surfaces at higher temperature? Control Film Growth with Thermal Energy

- What is the principal of CVD? A Guide to Chemical Vapor Deposition

- Why are graphite sample holders chosen to support silicon substrates? Key Benefits for Al2TiO5 Coating Purity.

- What does process robustness or productivity refer to in deposition systems? Optimize Your Manufacturing Workflow

- What are the disadvantages of CVD diamonds? Understanding the trade-offs for your purchase.

- What is the physical vapor deposition method? A Guide to High-Purity Thin Film Coatings

- What is vapor deposition process? A Guide to CVD and PVD Thin-Film Coating

- What is DC sputtering of metals? A Simple, Fast Method for High-Quality Metal Films