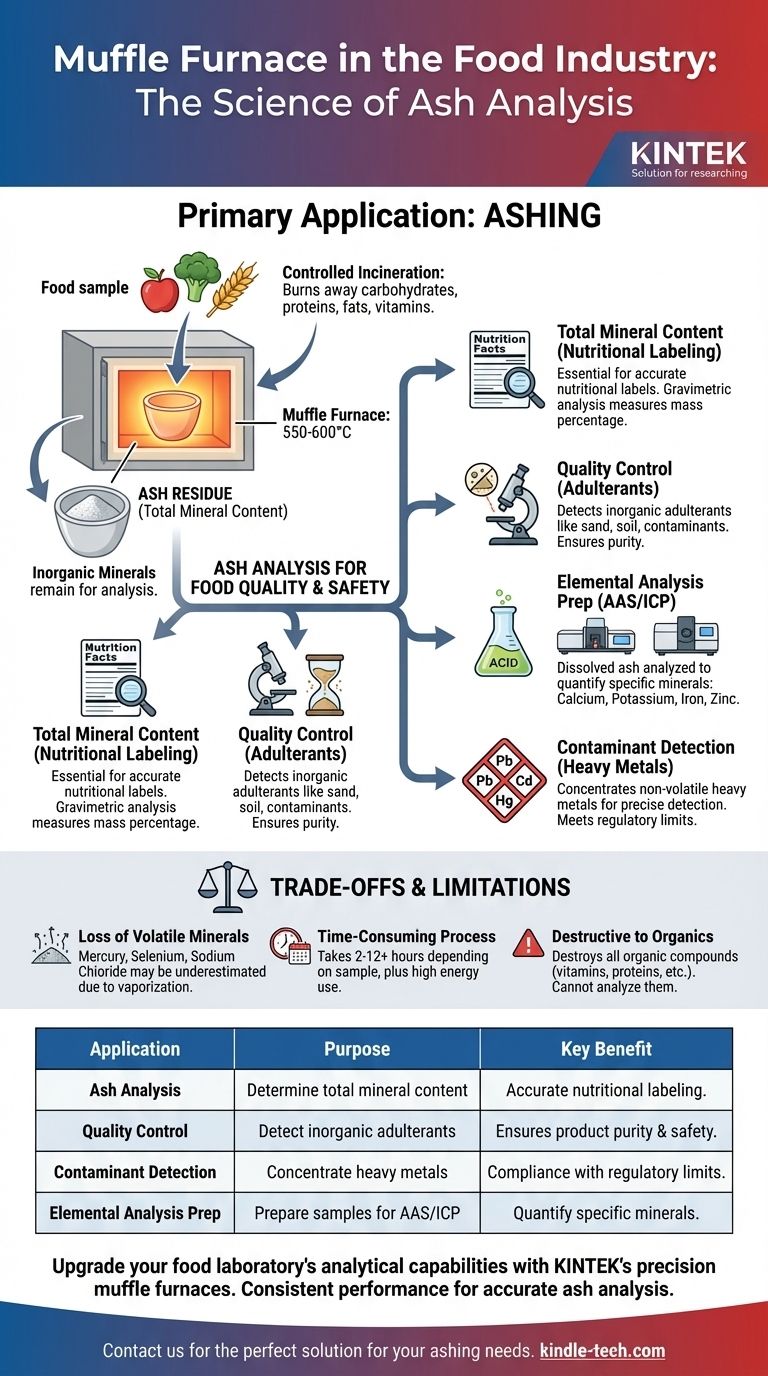

The primary application of a muffle furnace in the food industry is for ashing, a process used to determine the total mineral content of a food product. This is a fundamental step in nutritional analysis, quality control, and safety testing. By heating a food sample to extremely high temperatures (typically 550-600°C), the furnace incinerates all organic matter—carbohydrates, proteins, fats, and vitamins—leaving behind only the inorganic minerals.

While a muffle furnace is a high-temperature industrial tool, its role in the food sector is fundamentally analytical. It is used not to cook food, but to deconstruct it, revealing the mineral foundation essential for assessing nutritional value and ensuring safety.

The Core Principle: Ash Analysis for Food Quality

The use of a muffle furnace in the food industry is almost exclusively for a procedure known as dry ashing. This technique is a cornerstone of proximate analysis, the quantitative evaluation of food macronutrients.

What is Ashing?

Ashing is the process of controlled incineration. A precisely weighed food sample is placed in a ceramic or porcelain crucible and heated in the muffle furnace for several hours until all the organic material has burned away.

What Remains is "Ash"

The fine, whitish-gray powder that remains is referred to as ash. This residue represents the total mineral content of the original food sample. The weight of this ash is a critical data point for creating accurate nutritional labels.

Why This Matters for Quality Control

The total ash content serves as a general measure of quality. An unusually high ash value can indicate the presence of inorganic adulterants, such as sand, soil, or other contaminants, signaling a failure in processing or ingredient sourcing.

Beyond Total Ash: Further Analytical Uses

The ash produced by the muffle furnace is often just the first step in a more detailed analytical workflow. It prepares the sample for further testing.

Elemental Analysis

Once created, the ash can be dissolved in acid and analyzed using more advanced techniques like Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma (ICP). This allows for the precise quantification of individual essential minerals, such as calcium, potassium, iron, and zinc.

Contaminant Detection

This process is also critical for food safety. Ashing effectively concentrates non-volatile heavy metals like lead, cadmium, and mercury. This makes it easier to detect and measure these toxic elements, ensuring the food product complies with regulatory safety limits.

Gravimetric Analysis

At its heart, ashing is a form of gravimetric analysis—a method that relies on the measurement of mass. By comparing the weight of the sample before and after incineration, analysts can calculate the percentage of total minerals with high precision.

Understanding the Trade-offs and Limitations

While powerful, the dry ashing method performed in a muffle furnace has specific limitations that every analyst must consider.

Loss of Volatile Minerals

The extremely high temperatures can cause certain minerals and metallic salts to vaporize and be lost. Elements like mercury, selenium, and even compounds like sodium chloride can be underestimated, which is a known limitation of this method.

It Is Time-Consuming

The ashing process is not immediate. It can take anywhere from two to over twelve hours to complete, depending on the sample type and size. This, combined with high energy consumption, makes it a lengthy analytical step.

Destructive to Organic Components

It is crucial to understand that the muffle furnace destroys all organic information. It cannot be used to analyze vitamins, fats, proteins, or carbohydrates. Its purpose is strictly to isolate the inorganic components of a sample.

Making the Right Choice for Your Goal

The decision to use a muffle furnace depends entirely on your analytical objective.

- If your primary focus is determining total mineral content for nutritional labeling: Dry ashing in a muffle furnace is the standard, most direct method for calculating the "total ash" figure.

- If your primary focus is quantifying specific volatile minerals: A lower-temperature "wet ashing" process, which uses strong acids and heat to digest the sample without a furnace, may be more appropriate to prevent loss.

- If your primary focus is detecting heavy metal contaminants: Using a muffle furnace for ashing is an excellent preparatory step to concentrate the metals before analysis with spectroscopic instruments.

Ultimately, the muffle furnace serves as a powerful tool for breaking food down to its mineral foundation, ensuring both safety and accurate nutritional transparency.

Summary Table:

| Application | Purpose | Key Benefit |

|---|---|---|

| Ash Analysis | Determine total mineral content | Accurate nutritional labeling |

| Quality Control | Detect inorganic adulterants (e.g., sand, soil) | Ensures product purity and safety |

| Contaminant Detection | Concentrate heavy metals (e.g., lead, cadmium) for analysis | Compliance with regulatory limits |

| Elemental Analysis Prep | Prepare samples for AAS/ICP testing | Quantify specific minerals (e.g., calcium, iron) |

Upgrade your food laboratory's analytical capabilities with KINTEK's precision muffle furnaces.

Our furnaces are engineered to deliver the consistent, high-temperature performance required for accurate ash analysis, nutritional labeling, and contaminant detection. Whether you're in quality control, research, or production, KINTEK provides reliable lab equipment tailored to the rigorous demands of the food industry.

Contact us today to find the perfect solution for your ashing needs and ensure your products meet the highest standards of safety and transparency.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between a hot air oven and a muffle furnace? Choose the Right Tool for Your Thermal Process

- What is the function of muffle furnace in food industry? Ensure Accurate Ash Determination for Quality Control

- What is muffle furnace working principle and application? Achieve Contamination-Free High-Temperature Processing

- What are the components of a muffle furnace? Unlock the Core Systems for Precise, Safe Heating

- What is difference between muffle furnace and hot air oven? Choose the Right Heating Tool for Your Lab