Arc melting is a process that uses a high-energy electric arc to melt metals and create alloys. An arc is generated between graphite or carbon electrodes and the metallic raw materials (the "charge"), producing intense heat that can exceed 3,000°C (5,400°F) and rapidly liquefy the charge. It is a foundational method for large-scale production, particularly for alloy steels.

The core principle to understand is that arc melting is an exceptionally powerful and efficient method for melting large quantities of metal, but it is often just the first step. Achieving high-purity, high-quality alloys typically requires subsequent refining and degassing stages to remove impurities introduced during the aggressive melting process.

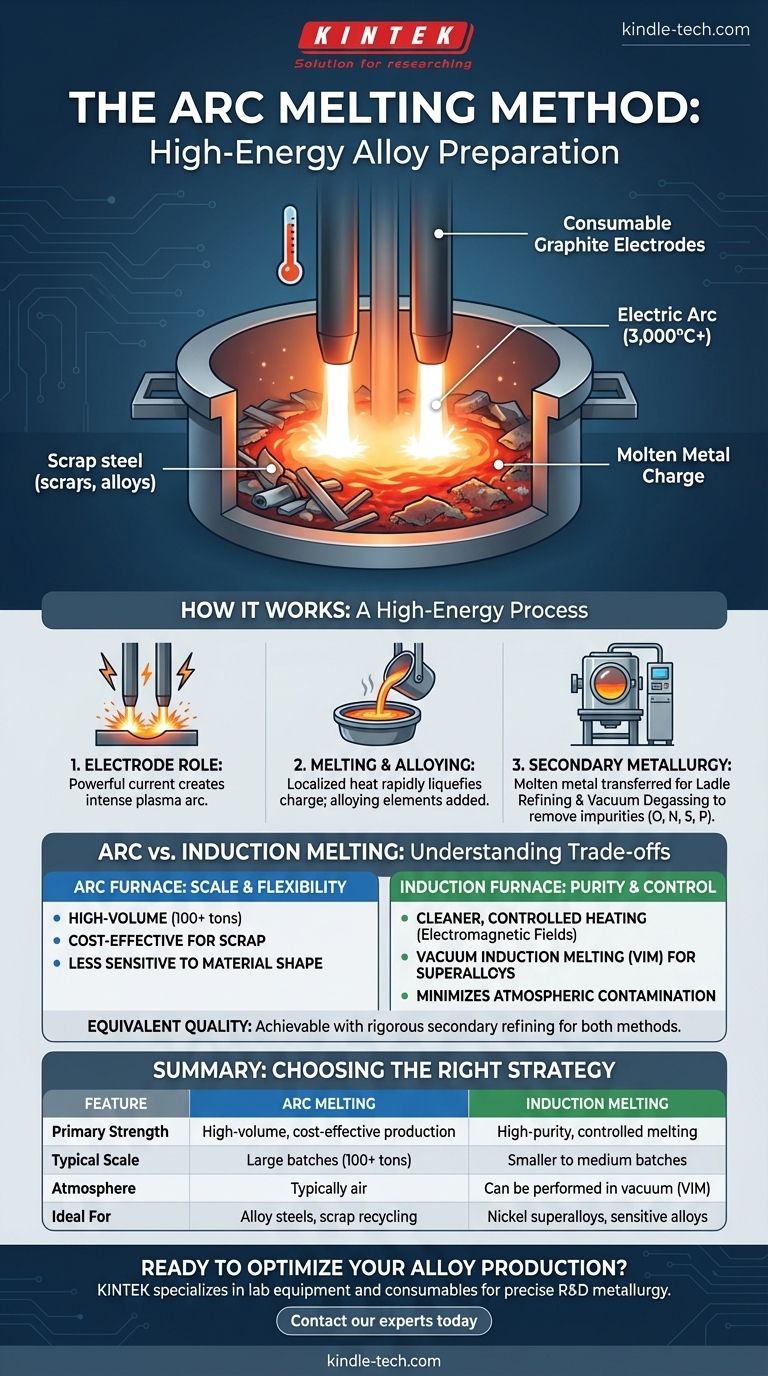

How the Arc Melting Process Works

The effectiveness of arc melting lies in its direct and intense application of energy. The process is straightforward but requires significant control to manage the extreme temperatures and molten metal chemistry.

The Role of Electrodes

The heart of the furnace is a set of consumable electrodes, typically made of graphite. A powerful electric current is passed through these electrodes.

When the electrodes are lowered close to the metal charge inside the furnace, a powerful electric arc is struck. This arc is essentially a continuous spark of plasma that transfers immense thermal energy directly to the metal.

Melting and Alloying

This intense, localized heat rapidly melts the raw materials, which can range from scrap steel to other pre-alloyed metals.

Once the primary charge is molten, alloying elements can be added directly to the liquid bath to achieve the desired chemical composition for the final product.

The Need for Secondary Metallurgy

Standard arc melting is a "raw" process often performed in air. This introduces oxygen and nitrogen into the molten metal and can fail to remove other impurities like sulfur and phosphorus from the raw materials.

To produce high-quality alloy steel, the molten metal is transferred from the arc furnace to a separate station for ladle refining and vacuum degassing. These secondary steps are critical for removing dissolved gases and unwanted elements, precisely tuning the final chemistry.

Understanding the Trade-offs: Arc vs. Induction Melting

The choice of melting technology is driven by the desired quality, production volume, and cost. Arc melting's main alternative is induction melting, and they serve different strategic purposes.

Advantage of Arc Furnaces: Scale and Flexibility

Arc furnaces excel at processing large volumes, often exceeding 100 tons per batch. They are highly effective at melting down scrap metal, making them a cost-effective choice for many types of steel production.

Their raw power makes them less sensitive to the quality and shape of the raw material charge compared to other methods.

Advantage of Induction Furnaces: Purity and Control

Induction furnaces use electromagnetic fields to heat the metal. This process is cleaner and more controlled, introducing fewer impurities.

For highly sensitive materials like nickel-based superalloys, vacuum induction melting (VIM) is often preferred. By performing the melt under a vacuum, it prevents contamination from the atmosphere, resulting in a much cleaner base metal.

Achieving Equivalent Quality

As the references note, the distinction in quality is not absolute. An induction furnace can produce a lower-quality steel if it skips the refining steps.

Conversely, if steel from an induction furnace undergoes the same rigorous ladle refining and vacuum degassing as steel from an arc furnace, the final quality can be identical. The key is the commitment to secondary refining, not just the initial melting method.

Making the Right Choice for Your Goal

The optimal melting strategy depends entirely on your operational priorities and the specifications of the final alloy.

- If your primary focus is high-volume, cost-effective production of alloy steels: The arc furnace, followed by a robust secondary refining process, is the industry standard.

- If your primary focus is producing smaller batches of extremely high-purity, specialized alloys (like superalloys): Vacuum induction melting is the superior choice for minimizing contamination from the start.

Ultimately, selecting the right melting technology is about matching the tool to the specific metallurgical objective you need to achieve.

Summary Table:

| Feature | Arc Melting | Induction Melting |

|---|---|---|

| Primary Strength | High-volume, cost-effective production | High-purity, controlled melting |

| Typical Scale | Large batches (often 100+ tons) | Smaller to medium batches |

| Atmosphere | Typically air | Can be performed in vacuum (VIM) for purity |

| Ideal For | Alloy steels, scrap metal recycling | Nickel superalloys, sensitive alloys |

Ready to optimize your alloy production process?

Whether you are scaling up production of alloy steels or require high-purity melting for specialized alloys, the right equipment is critical. KINTEK specializes in lab equipment and consumables, serving precise laboratory needs for research and development in metallurgy.

Contact our experts today to discuss how our solutions can help you achieve your specific metallurgical goals, from efficient melting to final quality control.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the vacuum arc remelting process? Producing Ultra-Pure, High-Performance Metal Alloys

- What is the remelting process? Achieve Ultimate Purity and Performance for High-Strength Alloys

- What is the benefit of vacuum arc remelting? Achieve Superior Metal Purity and Structural Integrity

- What is the overview of vacuum arc remelting? Achieve Ultra-Clean, High-Performance Alloys

- What is a remelting process? A Guide to High-Purity Metal Refinement