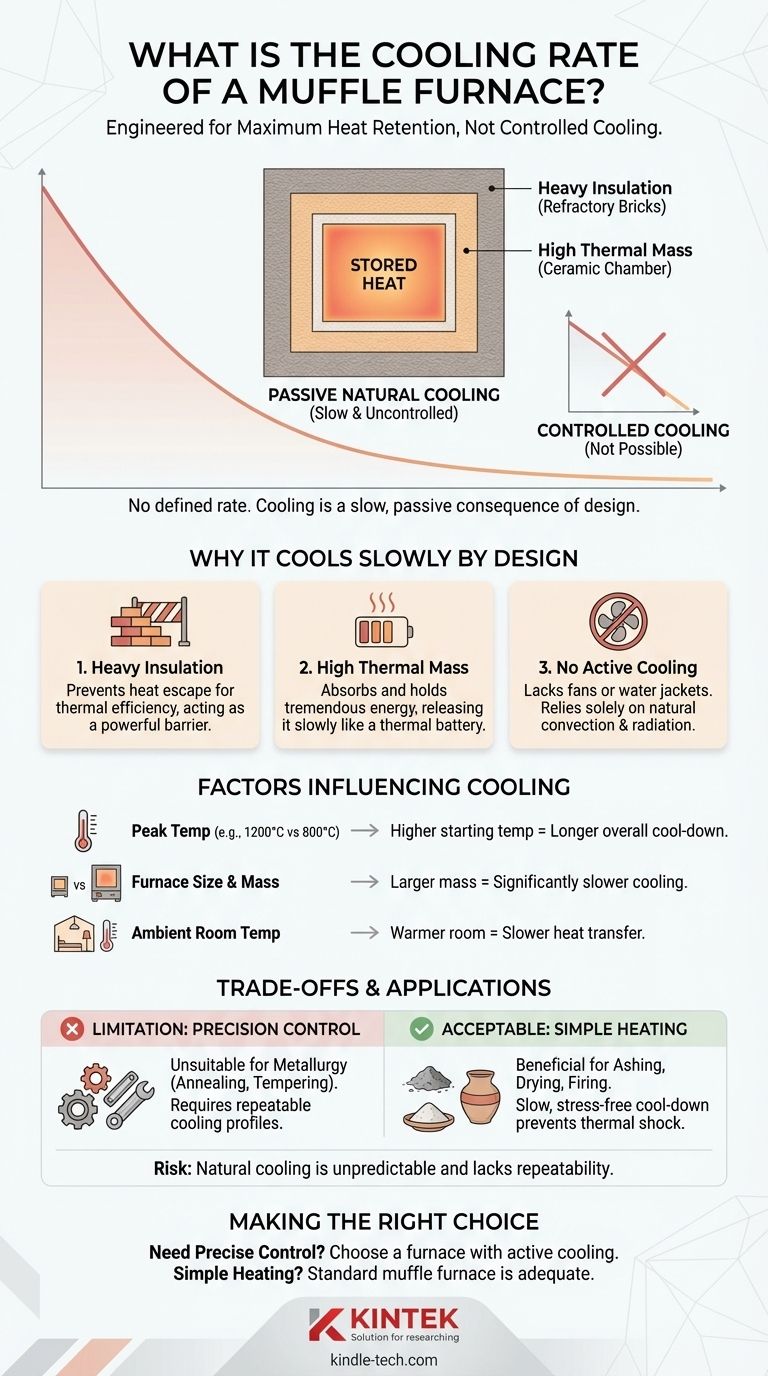

A standard muffle furnace does not have a single, defined cooling rate. Its design is fundamentally optimized for reaching and maintaining high temperatures by minimizing heat loss. Consequently, its natural cooling process is slow, passive, and highly dependent on factors like its size, insulation, and the ambient environment.

The central takeaway is that a muffle furnace is engineered for maximum heat retention, not for controlled cooling. Its natural cooling rate is therefore a slow, non-linear, and passive consequence of its design, making it unsuitable for processes that require a specific, repeatable cooling profile.

Why Muffle Furnaces Cool Slowly by Design

Understanding the core components of a muffle furnace reveals why its cooling is a passive, extended process. The very features that make it an excellent heater make it a poor cooler.

The Role of Heavy Insulation

A muffle furnace's chamber is lined with dense refractory bricks and ceramic insulation. The entire purpose of this material is to prevent heat from escaping, ensuring thermal efficiency and temperature stability. This insulation acts as a thermal barrier, dramatically slowing the rate at which heat can dissipate.

High Thermal Mass

The insulation and the ceramic muffle chamber itself absorb a tremendous amount of energy to reach a high operating temperature. This stored thermal energy, known as thermal mass, must be released slowly back into the environment. A furnace with high thermal mass acts like a thermal battery, holding its heat for a very long time after power is cut.

Lack of Active Cooling Mechanisms

Standard muffle furnaces are not equipped with active cooling systems. They lack components like cooling fans, water jackets, or controlled venting systems designed to actively remove heat from the chamber. Cooling relies entirely on natural convection and radiation from the furnace's exterior surfaces.

Factors Influencing the Uncontrolled Cooling Rate

While you cannot program the cooling rate, several factors determine how quickly a specific furnace will cool down naturally.

Peak Operating Temperature

A furnace operating at 1200°C has a much larger temperature differential with the surrounding room than one at 800°C. This will cause a faster initial rate of heat loss, but the overall time to reach room temperature will be significantly longer.

Furnace Size and Mass

A small laboratory muffle furnace will cool much faster than a large industrial production unit. The larger furnace has substantially more thermal mass and a lower surface-area-to-volume ratio, causing it to retain heat for many hours or even days.

Ambient Room Temperature

The furnace loses heat to its surroundings. A furnace in a cold room will cool slightly faster than the same furnace in a hot environment because the temperature gradient driving the heat transfer is steeper.

Understanding the Trade-offs: Natural Cooling vs. Process Control

The slow, passive cooling of a muffle furnace presents a critical limitation for certain applications.

The Limitation for Metallurgy

Processes like hardening, annealing, and tempering of metals often depend on precise cooling rates to achieve the desired crystalline structure and material properties. A standard muffle furnace's slow, uncontrolled cooling is completely unsuitable for these applications.

When Slow Cooling is Acceptable

For applications like ashing, drying samples, or certain ceramic and glass firing cycles, a slow, stress-free cool-down is often desirable to prevent thermal shock and cracking. In these cases, the furnace's natural cooling is a benefit.

The Risk of Unpredictability

Relying on natural cooling introduces a significant variable. The cooling curve can be affected by drafts in the room or changes in ambient temperature, leading to a lack of repeatability between process runs. This is unacceptable for most scientific research and quality-controlled industrial production.

Making the Right Choice for Your Goal

To get the results you need, you must match the furnace's capabilities to your process requirements.

- If your primary focus is precise process control (e.g., annealing, tempering, crystal growth): A standard muffle furnace is the wrong tool; you need a programmable furnace with active, controlled cooling capabilities.

- If your primary focus is simple heating followed by a non-critical cool-down (e.g., ashing, burn-off, basic ceramic firing): A standard muffle furnace's natural, slow cooling is perfectly adequate and often beneficial.

- If you need to cool faster than natural but without precision: Manually venting or cracking the door can speed cooling, but this introduces extreme temperature gradients and a high risk of damaging your workpiece from thermal shock.

Understanding that a muffle furnace is fundamentally a heat-retention device is the key to matching its capabilities to your specific technical goals.

Summary Table:

| Factor | Impact on Cooling Rate |

|---|---|

| Insulation | Heavy refractory bricks slow heat loss significantly. |

| Thermal Mass | High mass stores heat, leading to very slow cooling. |

| Active Cooling | Standard models lack fans or water jackets for fast cooling. |

| Furnace Size | Larger furnaces with more mass cool much slower. |

| Peak Temperature | Higher starting temperatures result in a longer overall cool-down time. |

Need precise temperature control for your processes?

A standard muffle furnace is designed for heat retention, not controlled cooling. If your applications—like metal annealing, tempering, or any process requiring repeatable cooling profiles—demand accuracy, you need a furnace with active cooling capabilities.

KINTEK specializes in lab equipment and can provide the right solution for your specific thermal processing needs, ensuring repeatability and quality in your results.

Contact our experts today to discuss your requirements and find the perfect furnace for your laboratory.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the disadvantages of wet ashing? Key Safety & Contamination Risks

- What heat can a muffle furnace produce? Achieve Precise High Temperatures Up to 1800°C

- What are the uses of furnace in chemistry laboratory? Unlock High-Temperature Material Synthesis and Analysis

- What is maintenance and how can you maintain the laboratory? Boost Lab Reliability & Data Integrity

- What is the process of dry ashing of sample treatment? A Guide to High-Temperature Mineral Analysis