The density of a sintered material is not a single, fixed value. It is a critical engineering parameter that is deliberately controlled during the manufacturing process. A sintered part can be designed to be nearly as dense as a solid, cast, or wrought material, or it can be engineered with a specific level of controlled porosity to meet functional requirements.

The core principle to understand is that sintered density is a design choice, not an inherent constant. It is adjusted by manipulating the sintering process to achieve a specific balance of properties, such as mechanical strength, weight, filtration capability, or cost.

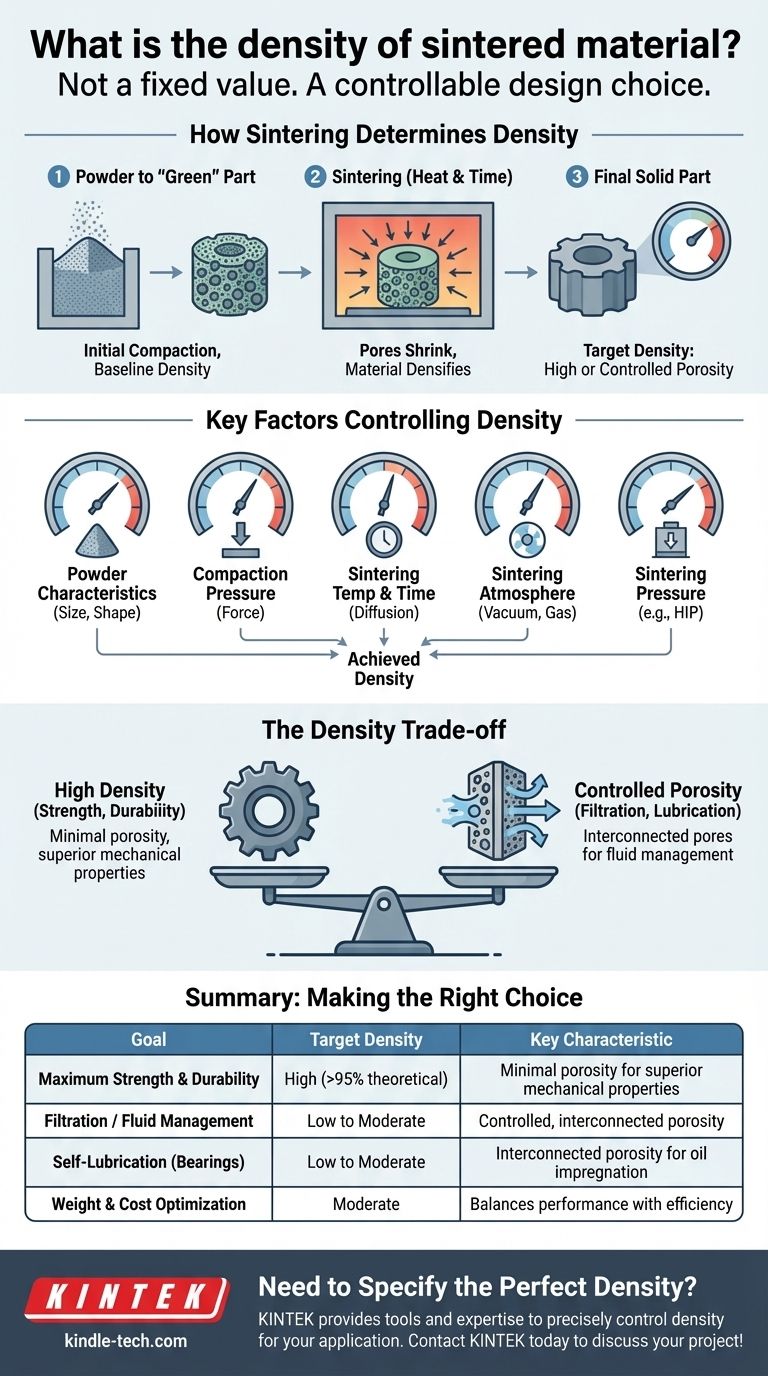

How Sintering Determines Material Density

Sintering is a manufacturing process that creates solid objects from powders using heat and pressure, without melting the material to the point of liquefaction. Understanding this process is key to understanding its effect on density.

From Powder to a Solid Part

The process begins with a fine metal or ceramic powder. This powder is poured into a mold and compacted under high pressure to form a "green" part. This initial compaction is what sets the baseline density.

The green part is then heated in a controlled-atmosphere furnace to a temperature below the material's melting point. This heat gives the powder particles enough energy to fuse, bonding them together and creating a solid, coherent piece.

The Role of Porosity

The initial spaces between the powder particles are known as pores. During the sintering process, these pores shrink and are gradually eliminated as the particles bond and the material densifies.

The final density of the part is determined by how much of this initial porosity remains. A part sintered to eliminate almost all pores will have a high density, while a part where porosity is intentionally retained will have a lower density.

The Key Factors Controlling Sintered Density

Engineers have several levers to pull to achieve a target density. The final properties of the material are a direct result of the careful control of these variables.

Powder Characteristics

The size, shape, and distribution of the initial powder particles play a significant role. Finer, more uniform powders can be packed together more tightly, leading to a higher starting density and a denser final product.

Compaction Pressure

The amount of pressure used to create the "green" part is critical. Higher compaction pressure forces the powder particles closer together, reducing initial porosity and making it easier to achieve high final densities during heating.

Sintering Temperature and Time

Higher temperatures and longer sintering times allow atoms to diffuse more effectively across particle boundaries. This atomic movement is what closes the pores and increases the material's density and strength.

Sintering Atmosphere

The atmosphere inside the furnace (e.g., vacuum, nitrogen, argon) is crucial. A controlled atmosphere prevents oxidation and can influence the chemical reactions at the particle surfaces, affecting how well they bond and densify.

Sintering Pressure

In some advanced methods like Hot Isostatic Pressing (HIP), pressure is applied during the heating cycle. This external pressure actively squeezes out porosity, allowing for the creation of parts that are virtually 100% dense.

Understanding the Trade-offs: Density vs. Performance

The decision to target a specific density is always a trade-off between different performance characteristics.

High Density for Strength and Durability

When maximum mechanical performance is required, the goal is to achieve the highest possible density. A denser part has fewer internal voids, which act as stress concentration points. This results in superior tensile strength, fatigue resistance, and impact toughness.

Controlled Porosity for Special Functions

In many applications, porosity is a desired feature. For example, porous sintered parts are used as filters, where the interconnected pores allow fluids to pass through. In self-lubricating bearings, the pores are impregnated with oil, which is released during operation to provide continuous lubrication.

Cost and Production Efficiency

Achieving extremely high densities often requires more energy, longer furnace times, or more complex equipment, which can increase production costs. For less demanding applications, a standard density may provide the necessary performance at a lower cost.

Making the Right Choice for Your Goal

The optimal density for a sintered part is entirely dependent on its intended application. When specifying a sintered component, consider the primary objective.

- If your primary focus is maximum strength and durability: Specify a high relative density, typically over 95% of the material's theoretical maximum, to minimize porosity.

- If your primary focus is filtration or fluid management: Define a target porosity level and pore size, which corresponds to a lower-density material.

- If your primary focus is self-lubrication: Require a specific level of interconnected porosity (and therefore a lower density) suitable for oil impregnation.

- If your primary focus is minimizing weight and cost: A moderate density that meets baseline performance requirements will often be the most economical choice.

Ultimately, mastering the density of a sintered part is the key to unlocking the full potential of this versatile manufacturing technology.

Summary Table:

| Goal | Target Density | Key Characteristic |

|---|---|---|

| Maximum Strength & Durability | High (Typically >95% theoretical) | Minimal porosity for superior mechanical properties. |

| Filtration / Fluid Management | Low to Moderate | Controlled, interconnected porosity. |

| Self-Lubrication (Bearings) | Low to Moderate | Interconnected porosity for oil impregnation. |

| Weight & Cost Optimization | Moderate | Balances performance with production efficiency. |

Need to Specify the Perfect Density for Your Sintered Component?

At KINTEK, we understand that the density of your sintered part is fundamental to its performance. Whether you require maximum strength for a demanding application, controlled porosity for filtration, or a cost-effective solution, our expertise in lab equipment and consumables for sintering processes can help you achieve your goals.

We provide the tools and support to precisely control the key factors—from powder characteristics to sintering parameters—ensuring your final product has the exact density and properties you need.

Let's engineer the ideal solution for your laboratory's needs. Contact KINTEK today to discuss your project!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What role does a precision laboratory oven play in the hydrothermal synthesis of copper sulfate nanocrystals?

- How does sintering temperature affect density? Optimize Your Process for Maximum Material Performance

- How do high-temperature furnaces facilitate the thermal treatment of halide solid electrolyte materials?

- Why do we need vacuum for deposition of thin films? To Ensure Purity and Uniformity in Your Coating Process

- How does heat transmit in a vacuum? Mastering Thermal Radiation for Purity & Precision

- Is it better to weld or braze aluminum? Maximize Strength or Minimize Distortion

- What role do high-temperature furnaces play in ternary alloy phase equilibrium? Precision Tools for Stable Diffusion

- What is the function of a vacuum arc melting furnace? Master Homogeneity for Fe-Co Metallic Glasses