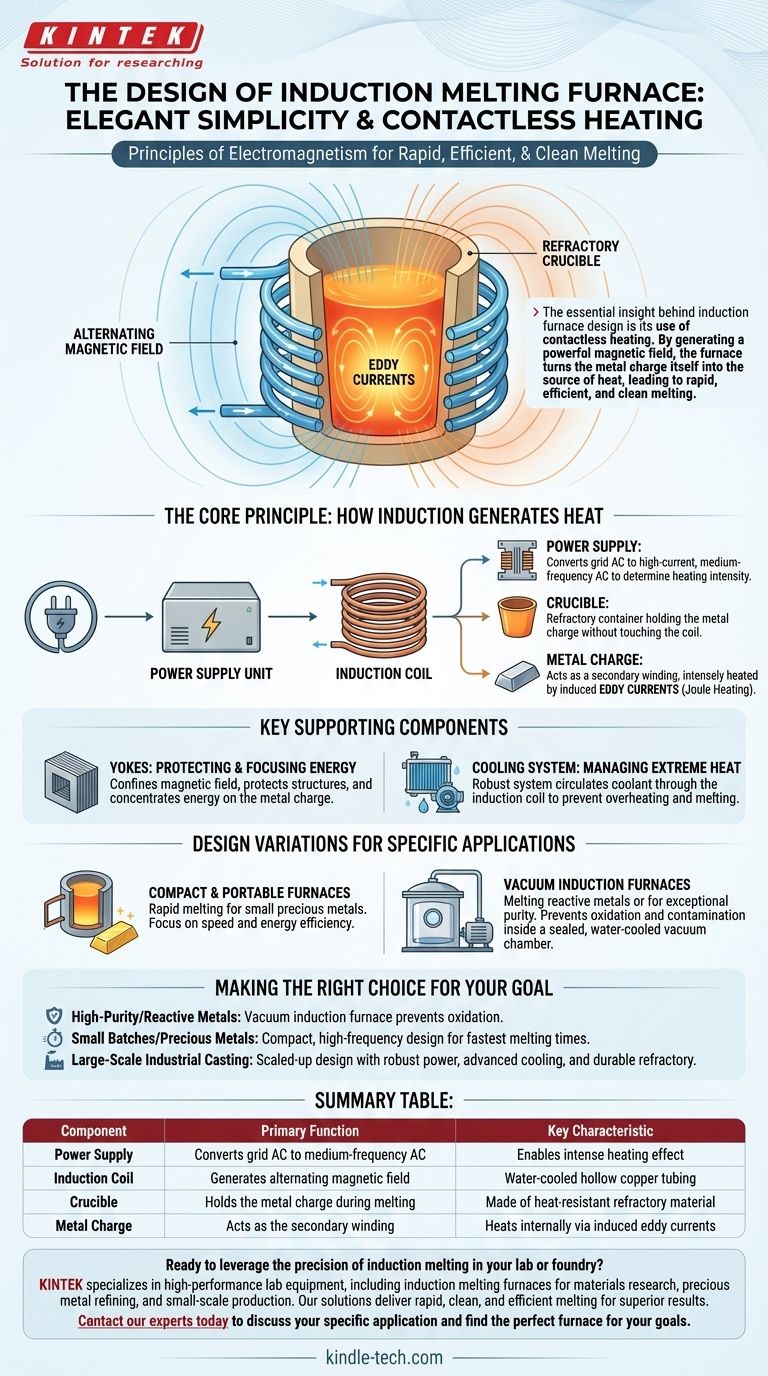

At its core, the design of an induction melting furnace is elegantly simple. It consists of three primary components: a specialized power supply, a water-cooled induction coil, and a crucible made from refractory material. The design's purpose is to use the principles of electromagnetism to heat and melt a conductive metal charge placed within the crucible, without any direct contact from a heating element.

The essential insight behind induction furnace design is its use of contactless heating. By generating a powerful magnetic field, the furnace turns the metal charge itself into the source of heat, leading to rapid, efficient, and clean melting.

The Core Principle: How Induction Generates Heat

The entire design is built around the principle of electromagnetic induction, functioning much like a transformer. The furnace’s induction coil acts as the primary winding, while the metal to be melted acts as a single-turn secondary winding.

The Power Supply: The Engine of the Furnace

The process begins with the power supply. This sophisticated unit converts standard, low-frequency alternating current (AC) from the grid into a high-current, medium-frequency AC.

This frequency conversion is critical because it determines the intensity of the heating effect.

The Induction Coil: Creating the Magnetic Field

The medium-frequency current is sent through a multi-turn coil, typically made of hollow copper tubing. A coolant, usually water, is circulated through this tubing to manage the immense heat generated during operation.

This energized coil produces a strong, rapidly alternating magnetic field in the space within and around it.

The Crucible: Containing the Melt

The crucible is a container made of heat-resistant (refractory) material that sits inside the induction coil but does not touch it. Its job is to hold the metal charge securely as it transitions from a solid to a liquid state.

The material of the crucible is chosen carefully to withstand extreme temperatures and avoid reacting with the molten metal, ensuring the purity of the final product.

The Metal Charge: The Target of Induction

When the conductive metal charge is placed inside the crucible, the magnetic field from the coil passes through it. This changing magnetic field induces powerful electrical currents within the metal itself, known as eddy currents.

The metal's natural electrical resistance fights against the flow of these eddy currents, generating immense heat through a process called Joule heating. This internal heat generation is what causes the metal to melt rapidly and efficiently.

Key Supporting Components in the Design

While the power supply, coil, and crucible form the core, other components are essential for safe and efficient operation.

Yokes: Protecting and Focusing Energy

Magnetic yokes, typically made of laminated steel, are often placed around the outside of the coil. They serve a dual purpose: they provide structural support and, more importantly, they confine the magnetic field, preventing it from escaping and heating nearby structural components.

This also helps to concentrate the magnetic energy on the metal charge, improving the furnace's overall efficiency.

Cooling System: Managing Extreme Heat

The induction coil carries enormous electrical current, which generates significant heat. A robust water-cooling system is essential to prevent the copper coil itself from overheating and melting.

This system is a critical safety and operational feature of any induction furnace design.

Design Variations for Specific Applications

The fundamental design of an induction furnace can be adapted to suit specific needs, from small-scale jewelry making to large industrial foundries.

Compact and Portable Furnaces

For melting smaller quantities of precious metals like gold or silver, furnaces are designed to be compact and lightweight. These units prioritize rapid temperature rise and energy efficiency, often capable of melting a small batch in just a few minutes.

Vacuum Induction Furnaces

When melting highly reactive metals (like titanium) or when exceptional purity is required, a vacuum induction furnace is used. This design places the entire coil and crucible assembly inside a sealed, water-cooled stainless steel chamber.

A high-vacuum pumping system removes air and other gases, preventing the molten metal from oxidizing or becoming contaminated during the process.

Making the Right Choice for Your Goal

The optimal furnace design depends entirely on the material being melted and the desired outcome.

- If your primary focus is high-purity or reactive metals: A vacuum induction furnace design is necessary to prevent oxidation and contamination from the atmosphere.

- If your primary focus is small batches or precious metals: A compact, high-frequency design will provide the fastest melting times and greatest energy efficiency.

- If your primary focus is large-scale industrial casting: The core design principles are scaled up, requiring more robust power delivery, advanced cooling systems, and durable refractory linings.

Ultimately, the design of an induction furnace is a masterclass in controlled, contactless energy transfer, tailored to the specific demands of the material being melted.

Summary Table:

| Component | Primary Function | Key Characteristic |

|---|---|---|

| Power Supply | Converts grid AC to medium-frequency AC | Enables intense heating effect |

| Induction Coil | Generates alternating magnetic field | Water-cooled hollow copper tubing |

| Crucible | Holds the metal charge during melting | Made of heat-resistant refractory material |

| Metal Charge | Acts as the secondary winding | Heats internally via induced eddy currents |

Ready to leverage the precision of induction melting in your lab or foundry?

KINTEK specializes in high-performance lab equipment, including induction melting furnaces tailored for materials research, precious metal refining, and small-scale production. Our solutions deliver the rapid, clean, and efficient melting you need to achieve superior results.

Contact our experts today to discuss your specific application and find the perfect furnace for your goals.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting