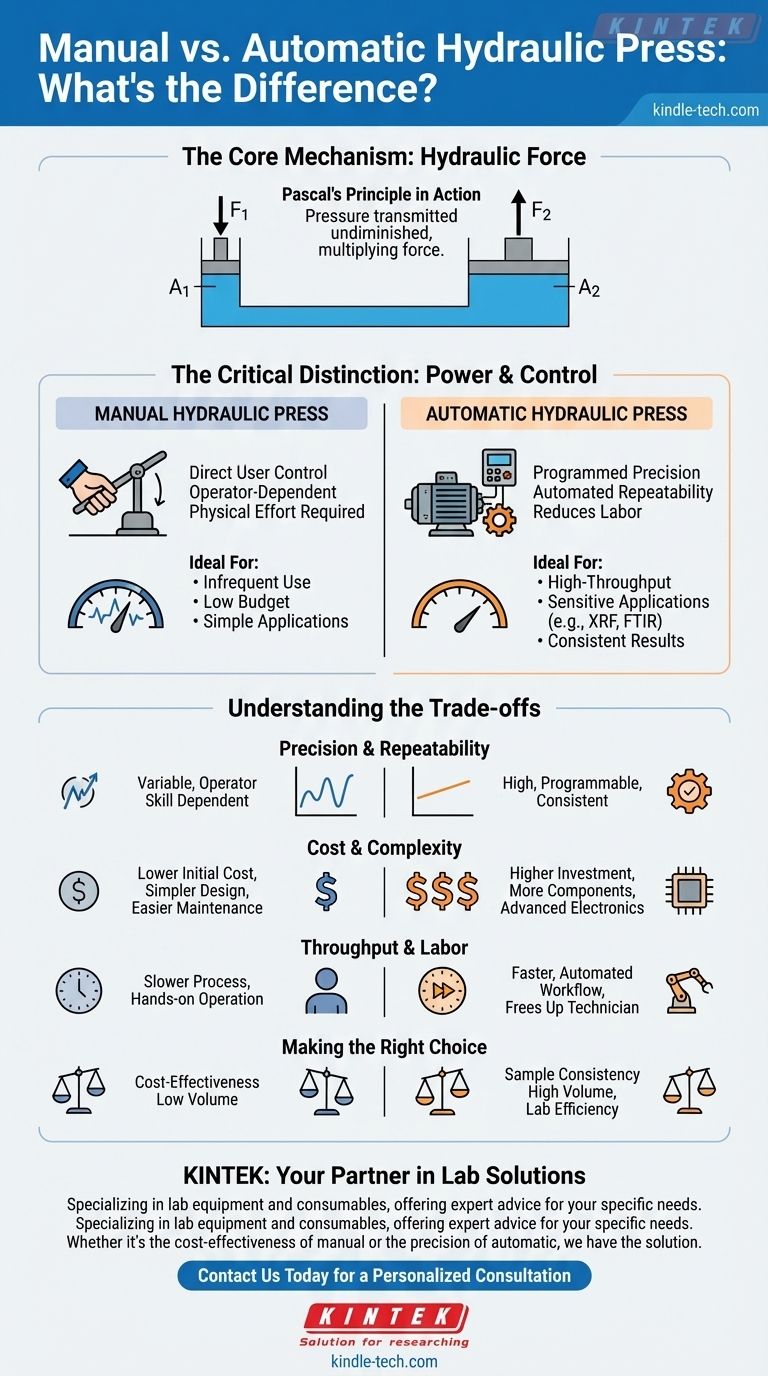

The fundamental difference between these presses is not manual versus hydraulic, but rather how the hydraulic force is generated and controlled. A "manual press" in this context is a manual hydraulic press, which uses a hand-operated pump to create pressure. An automatic press is an automatic hydraulic press that uses an electric motor and programmable controls to achieve the same goal with greater precision and less effort.

The choice between a manual and an automatic hydraulic press comes down to a trade-off between cost and control. Manual presses offer a simple, low-cost solution ideal for infrequent use, while automatic presses provide the repeatability, precision, and efficiency required for high-throughput and sensitive applications.

The Core Mechanism: What Makes a Press "Hydraulic"?

At their heart, both manual and automatic presses discussed here are hydraulic. They rely on the same core principle to generate immense force from a small input.

Pascal's Principle in Action

A hydraulic press works by using a confined, incompressible fluid—typically oil—to transmit and multiply force. This is an application of Pascal's Principle, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, applying a small force to a small piston creates pressure in the hydraulic oil. This pressure then acts on a much larger piston, multiplying the initial force significantly and allowing the press to exert tons of pressure on a workpiece.

The Piston and Cylinder System

Both press types use this system. The key difference lies in how the oil is pressurized. A pump pushes oil into the main cylinder, driving the large piston down to apply force. Releasing a valve allows the oil to flow back out, retracting the piston.

Manual vs. Automatic: The Critical Distinction

The real difference is the source of power and control for the hydraulic pump. This dictates the press's performance, cost, and ideal use case.

The Manual Hydraulic Press: Direct User Control

In a manual hydraulic press, the operator is the power source. You physically pump a hand-operated lever to build pressure in the hydraulic cylinder.

The operator watches a pressure gauge and decides when the target force has been reached. This process requires physical effort and skill to achieve consistent results from one sample to the next.

The Automatic Hydraulic Press: Programmed Precision

An automatic hydraulic press replaces the hand lever with an electric motor that drives the pump. The entire process can be programmed and automated.

An operator can set a target pressure, and the machine will apply and hold that exact force autonomously. This removes operator-to-operator variability and ensures every sample is treated identically, which is critical for scientific analysis.

Understanding the Trade-offs

Choosing between these two systems requires weighing their respective strengths and weaknesses against your specific needs.

Precision and Repeatability

A manual press's repeatability is entirely dependent on the operator's skill. Different users may apply slightly different loads, potentially affecting results in sensitive applications like XRF or FTIR sample preparation, where pellet consistency is key.

An automatic press excels at repeatability. Once programmed, it delivers the exact same force profile every time, eliminating a major source of experimental error and improving data quality.

Cost and Complexity

Manual hydraulic presses have a simpler design with no motors or electronics. This makes them significantly less expensive to purchase and easier to maintain, as there are fewer components that can fail.

Automatic presses are a larger capital investment due to the inclusion of an electric motor, pump, and electronic control systems.

Throughput and Labor

Operating a manual press is a physical, hands-on process. It is perfectly suitable for occasional use or in a lab with a low volume of samples.

For busy laboratories, an automatic press significantly improves workflow and reduces labor. It operates faster, frees up the technician to perform other tasks, and eliminates the physical strain of manual pumping.

Making the Right Choice for Your Application

To select the correct press, you must first define your primary goal.

- If your primary focus is cost-effectiveness for infrequent use: A manual hydraulic press is the clear choice, offering powerful performance for a minimal investment.

- If your primary focus is high-throughput or absolute sample consistency: An automatic hydraulic press is necessary to ensure repeatability and improve lab efficiency.

- If your primary focus is preparing samples for sensitive analysis (e.g., KBr pellets for FTIR): An automatic press is strongly recommended to eliminate pressure variations as a variable in your results.

By understanding that the core difference lies in the control system, you can confidently select the press that aligns with your lab's specific needs for precision, budget, and workflow.

Summary Table:

| Feature | Manual Hydraulic Press | Automatic Hydraulic Press |

|---|---|---|

| Power Source | Hand-operated lever | Electric motor |

| Precision & Repeatability | Operator-dependent | Programmable, high repeatability |

| Cost | Lower initial cost | Higher initial investment |

| Ideal For | Infrequent use, low budget | High-throughput, sensitive applications (e.g., XRF, FTIR) |

| Labor & Throughput | Hands-on, slower | Automated, frees up technician time |

Still unsure which press is right for your laboratory? The team at KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert advice and high-quality solutions. Whether you require the cost-effectiveness of a manual press or the precision of an automatic system for sensitive applications like FTIR sample preparation, we can help you select the ideal equipment to improve your workflow and data consistency.

Contact us today for a personalized consultation and let KINTEK enhance your lab's efficiency!

Visual Guide

Related Products

- Manual Lab Heat Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What does a manual press do? Understand the Two Key Types for Your Lab or Industrial Needs

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation

- What are the potential hazards in a hydraulic press? Understanding the Risks of Crushing, Injection, and Failure