At a glance, the fundamental difference between an oven and a muffle furnace lies in their maximum temperature and method of heating. A laboratory oven typically operates at lower temperatures (up to ~300°C) and heats samples via convection, circulating hot air directly around them. A muffle furnace achieves much higher temperatures (often over 1000°C) by using heating elements to heat a separate, insulated inner chamber—the "muffle"—which then radiates heat onto the sample, isolating it from direct contact with the elements.

The core distinction is not just about temperature, but about control and isolation. An oven is for uniform, low-temperature processing in air, while a muffle furnace is for high-energy transformations that often require protecting the sample from the heating source and vice versa.

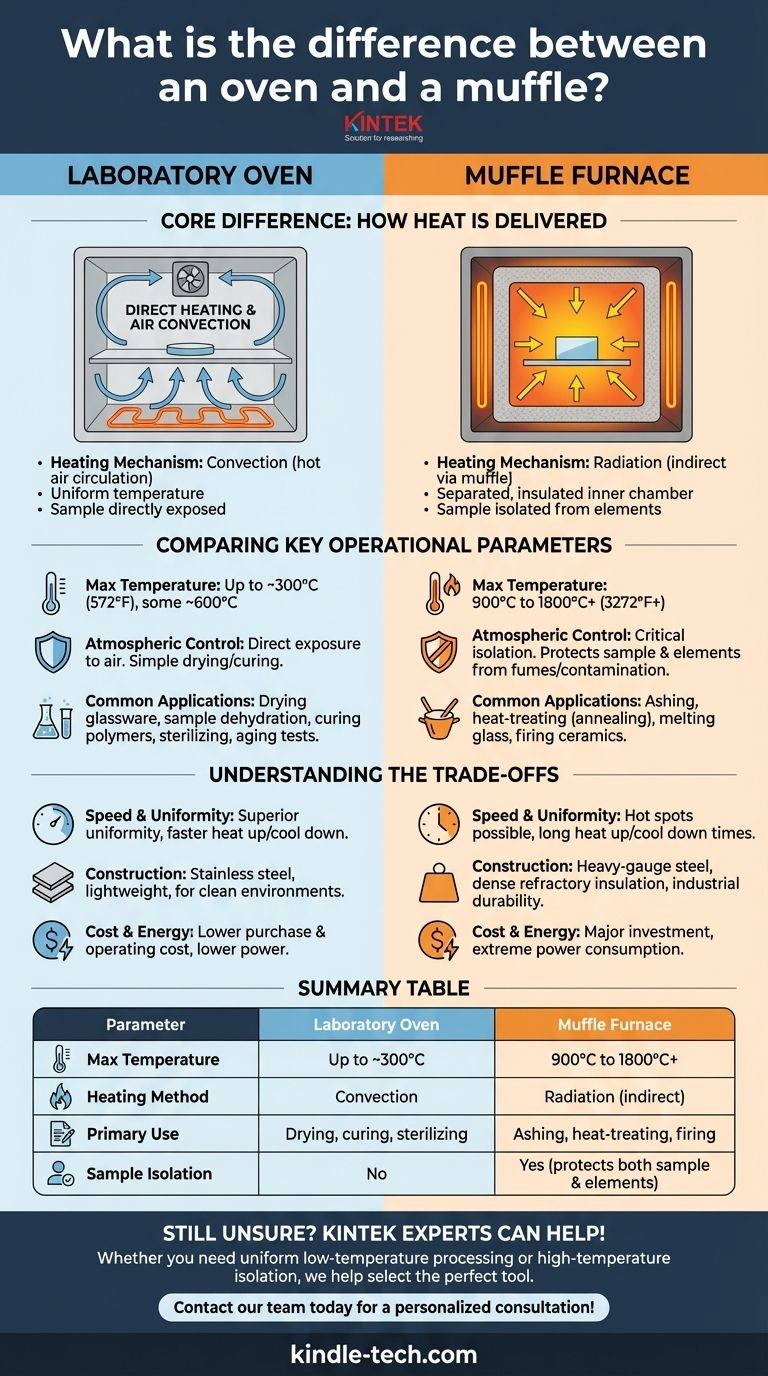

The Defining Difference: How Heat is Delivered

The most critical distinction between these two instruments is their core heating mechanism. This design choice dictates their temperature range, applications, and limitations.

Ovens: Direct Heating and Air Convection

An oven operates much like a high-performance kitchen convection oven. The heating elements are typically located within the main chamber.

A fan actively circulates the air heated by these elements, ensuring a uniform temperature distribution throughout the chamber. This method is highly efficient for processes that require consistent heat applied to all surfaces of a sample.

Muffle Furnaces: Indirect, Radiated Heat

A muffle furnace contains an inner chamber, or muffle, made of a high-temperature refractory ceramic. The heating elements are outside this muffle.

The elements heat the muffle to a very high temperature, and the muffle then radiates that thermal energy evenly inward to heat the sample. This design isolates the sample from the raw heating elements.

Comparing Key Operational Parameters

The difference in heating methods leads to significant contrasts in performance, materials, and suitable applications.

Maximum Temperature

Ovens are designed for lower temperature applications, typically ranging from slightly above ambient to around 300°C (572°F), with some specialized models reaching 600°C.

Muffle furnaces are built for extreme heat. Their standard operating range begins where ovens leave off, commonly running from 900°C to 1800°C (3272°F) or even higher.

Atmospheric Control and Isolation

In an oven, the sample is directly exposed to the heating elements and the circulating air. This is ideal for simple drying or curing.

The design of a muffle furnace provides critical isolation. It protects the sample from contamination by the heating elements. More importantly, it protects the heating elements from any corrosive fumes or vapors released by the sample during heating, which is crucial in processes like ashing.

Common Applications

Oven applications include drying glassware, sample dehydration, curing polymers and coatings, sterilizing equipment, and accelerated aging tests.

Muffle furnace applications are high-energy processes like ashing materials for gravimetric analysis, heat-treating metals (annealing, hardening), melting glass, and firing ceramics.

Understanding the Trade-offs

Choosing the wrong instrument can lead to failed processes, damaged equipment, or inaccurate results. Understanding their inherent trade-offs is key.

Speed and Uniformity

At lower temperatures, a fan-assisted convection oven generally provides superior temperature uniformity and can reach its set point more quickly.

A muffle furnace relies on radiant heat, which can create hot spots, and its massive thermal insulation means it takes significantly longer to both heat up and cool down.

Construction and Materials

Ovens are typically constructed with stainless steel interiors and exteriors. They are relatively lightweight and designed for clean environments.

Muffle furnaces are built with heavy-gauge steel exteriors and dense, multi-layered refractory brick or ceramic fiber insulation. They are extremely heavy and built for industrial durability.

Cost and Energy Consumption

Due to their simpler construction and lower temperature components, ovens are significantly less expensive to purchase and operate.

The specialized materials, complex wiring, and extreme power required to reach 1000°C+ make muffle furnaces a major investment in both initial cost and ongoing energy consumption.

Making the Right Choice for Your Application

Selecting the correct instrument is a simple matter of matching the tool to the thermal requirements of your specific process.

- If your primary focus is drying, curing, or sterilizing below 300°C: An oven provides the uniform, efficient heating you need.

- If your primary focus is ashing, melting, or heat-treating materials above 900°C: A muffle furnace is the only tool that can safely and effectively reach these temperatures.

- If your primary focus is protecting your sample from contamination or the heating elements from corrosive off-gassing: The isolated chamber of a muffle furnace is essential.

Understanding the fundamental difference in heat delivery—direct convection versus indirect radiation—empowers you to select the precise tool for your thermal processing needs.

Summary Table:

| Parameter | Laboratory Oven | Muffle Furnace |

|---|---|---|

| Max Temperature | Up to ~300°C (572°F) | 900°C to 1800°C+ (3272°F+) |

| Heating Method | Convection (hot air circulation) | Radiation (indirect via insulated muffle) |

| Primary Use | Drying, curing, sterilizing | Ashing, heat-treating, firing ceramics |

| Sample Isolation | No | Yes (protects sample and heating elements) |

Still unsure which heating equipment is right for your specific application?

At KINTEK, we specialize in providing the precise lab equipment and consumables your laboratory needs. Whether you require the uniform, low-temperature processing of an oven or the high-temperature, isolated environment of a muffle furnace, our experts can help you select the perfect tool to ensure accurate results and protect your valuable samples.

Let us help you optimize your thermal processes. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the safety precautions for heat experiment? Essential Steps to Prevent Lab Burns and Accidents

- How do you cool down a muffle furnace? Ensure Longevity and Safety with the Correct Procedure

- What are the risks of using a muffle furnace? Mitigate Thermal, Material, and Operational Hazards

- What is the objective of a muffle furnace? Achieve Pure, High-Temperature Processing

- What is the working principle of laboratory muffle furnace? Achieve Contamination-Free High-Temperature Processing