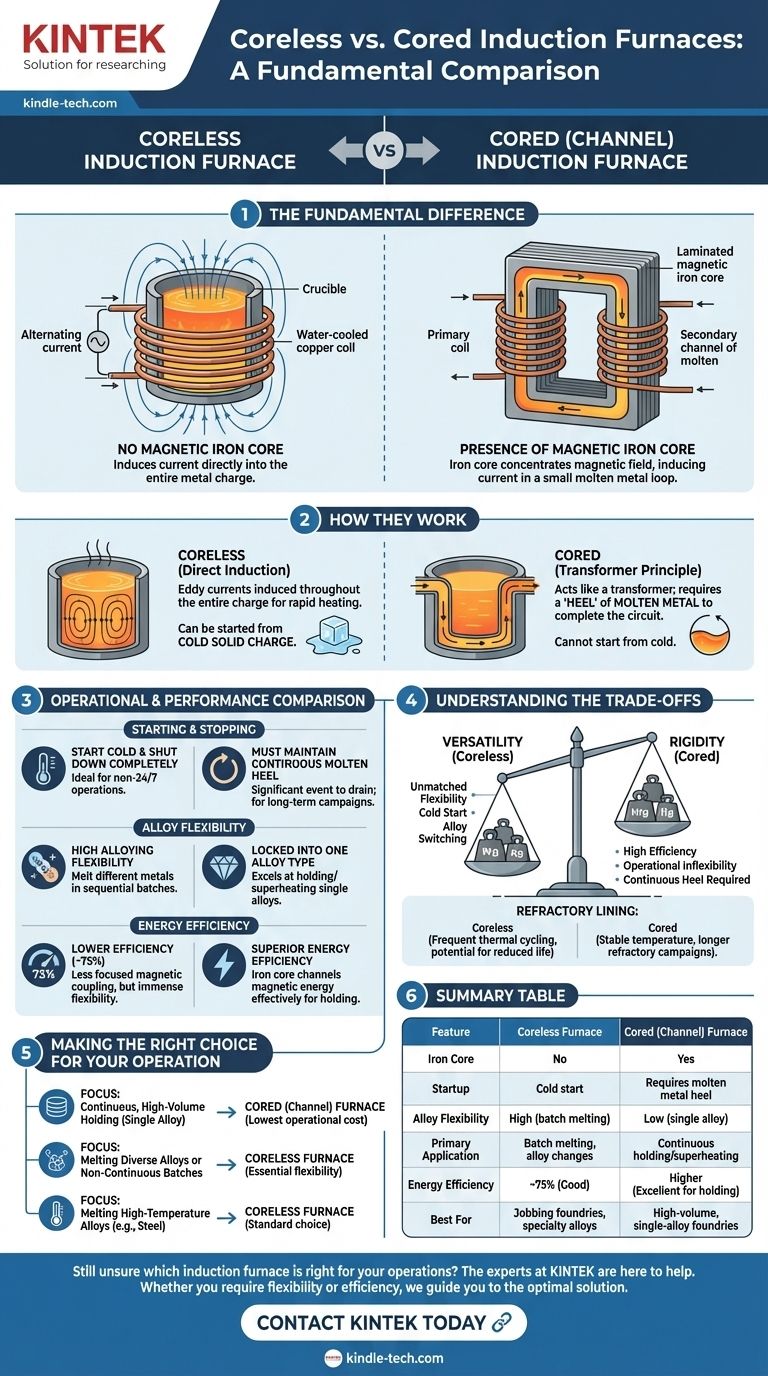

At its core, the fundamental difference between a coreless and a cored induction furnace is the presence of a magnetic iron core. A cored furnace, also known as a channel furnace, uses an iron core to concentrate the magnetic field and induce current in a small loop of molten metal. A coreless furnace has no such core; it induces current directly into the entire metal charge contained within a crucible.

The choice between these two designs is a strategic trade-off. Cored (channel) furnaces offer superior energy efficiency for holding large, continuous volumes of a single metal, while coreless furnaces provide the operational flexibility to melt diverse alloys from a cold start.

The Fundamental Design Difference

The presence or absence of an iron core dictates how each furnace operates, its applications, and its efficiency profile. The two designs function on entirely different principles of induction.

How a Cored (Channel) Furnace Works

A cored furnace operates much like a transformer. It has a primary coil wrapped around an iron core, which creates a strong, concentrated magnetic field.

A separate, continuous loop or "channel" of molten metal passes through this core, acting as a single-turn secondary winding. The intense magnetic field induces a powerful current within this metal loop, generating heat efficiently.

This design requires a "heel" of molten metal to be present at all times to complete the circuit, meaning it cannot be started from a cold, solid state.

How a Coreless Furnace Works

A coreless furnace consists of a refractory crucible that holds the metal charge. This crucible is surrounded by a water-cooled copper coil.

When alternating current passes through the coil, it generates a magnetic field that couples directly with the metal inside the crucible. This induces eddy currents throughout the entire charge, rapidly heating and melting it.

Because it acts on the entire charge at once and has no required secondary loop, a coreless furnace can be started with a completely cold, solid charge.

Operational and Performance Comparison

The design differences lead to distinct advantages and disadvantages in a production environment. Understanding these is key to selecting the right tool for your metallurgical process.

Starting and Stopping

A coreless furnace's greatest advantage is its ability to be started cold and shut down completely. This makes it ideal for operations that do not run 24/7 or that need to change alloys frequently.

A cored furnace must maintain a continuous molten heel to operate. Draining the furnace completely is a significant event, making it suitable only for continuous, long-term campaigns on a single alloy.

Application and Alloy Flexibility

The coreless furnace is the clear choice for alloying flexibility. You can melt a batch of steel, empty the furnace, and then melt a batch of a different metal.

The cored furnace is functionally locked into one alloy type for extended periods. It excels as a holding and superheating unit in large foundries, such as for cast iron, where a consistent supply of molten metal is always needed.

Energy Efficiency

For its specific task of holding large volumes of molten metal at a constant temperature, the cored (channel) furnace is more energy-efficient. The iron core effectively channels all magnetic energy into the small metal loop.

The coreless furnace is generally less efficient, often cited with an electrical efficiency around 75%. The magnetic coupling is less focused, though this is the price paid for its immense flexibility.

Understanding the Trade-offs

Neither furnace is universally superior; they are specialized tools with inherent compromises.

The Rigidity of Cored Furnaces

The primary trade-off for a cored furnace's high efficiency is its operational inflexibility. The need to maintain a molten heel makes it unsuitable for batch work or frequent alloy changes. It is a dedicated, single-purpose machine.

The Versatility of Coreless Furnaces

The coreless furnace trades peak efficiency for unmatched versatility. The ability to start cold and switch alloys is a critical capability for jobbing foundries, research facilities, and producers of specialty alloys.

Refractory Lining Considerations

While versatile, the frequent thermal cycling (heating and cooling) and potential for chemical attack from different alloys in a coreless furnace can reduce the life of its refractory lining. A cored furnace, held at a relatively stable temperature, generally offers longer refractory campaigns.

Making the Right Choice for Your Operation

Selecting the correct furnace technology depends entirely on your production goals.

- If your primary focus is continuous, high-volume holding of a single alloy: A cored (channel) furnace offers the lowest operational cost and highest energy efficiency.

- If your primary focus is melting diverse alloys or running non-continuous batches: A coreless furnace provides the essential flexibility to start, stop, and change materials.

- If your primary focus is melting high-temperature alloys like steel: A coreless furnace is the standard and most practical choice for this application.

Understanding this fundamental design distinction empowers you to select the precise technology that aligns with your operational needs.

Summary Table:

| Feature | Coreless Furnace | Cored (Channel) Furnace |

|---|---|---|

| Iron Core | No | Yes |

| Startup | Cold start | Requires molten metal heel |

| Alloy Flexibility | High (batch melting) | Low (single alloy) |

| Primary Application | Batch melting, alloy changes | Continuous holding/superheating |

| Energy Efficiency | ~75% (Good) | Higher (Excellent for holding) |

| Best For | Jobbing foundries, specialty alloys | High-volume, single-alloy foundries |

Still unsure which induction furnace is right for your laboratory or foundry operations? The experts at KINTEK are here to help. We specialize in providing the ideal lab equipment and consumables for your specific metal melting needs. Whether you require the flexibility of a coreless furnace or the efficiency of a cored system, we can guide you to the optimal solution.

Contact KINTEL today to discuss your application and receive a personalized recommendation. Let us help you enhance your process efficiency and achieve superior results.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications