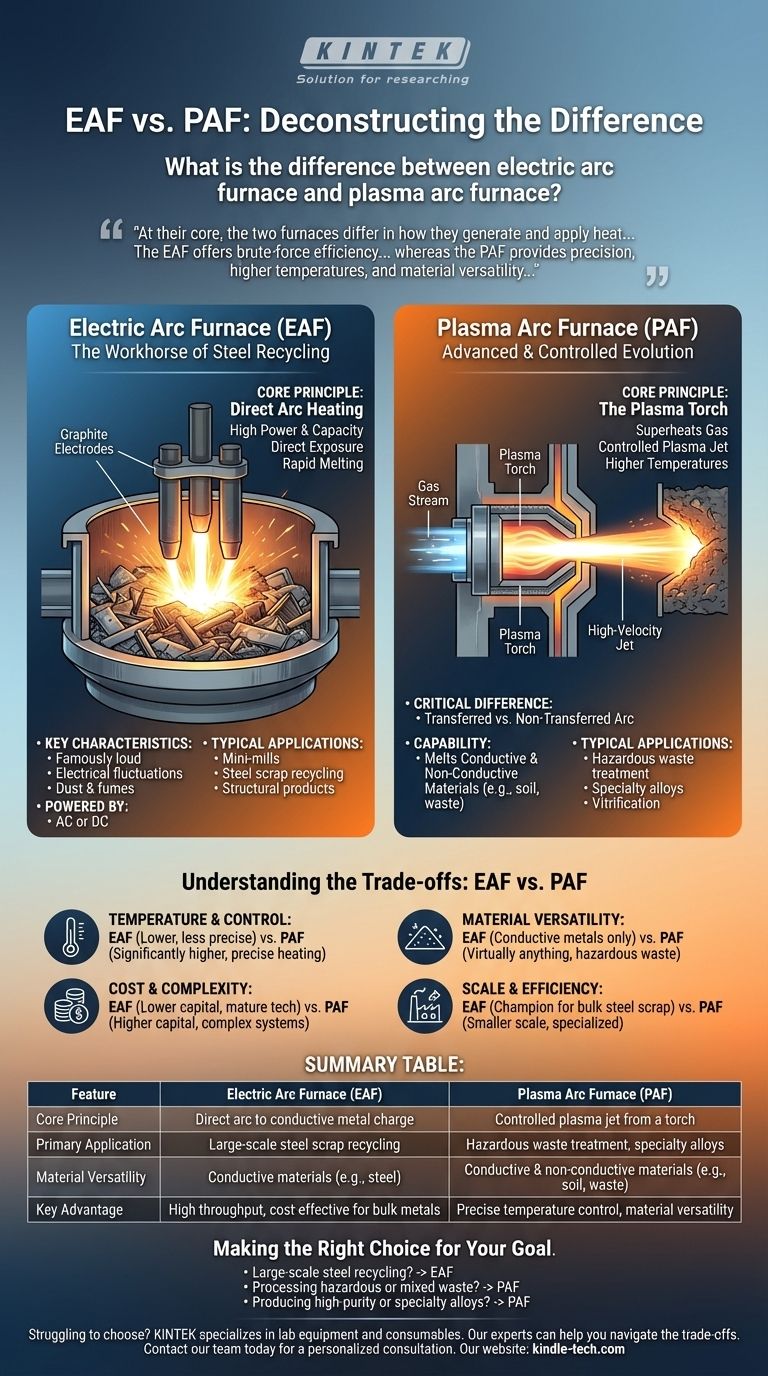

At their core, the two furnaces differ in how they generate and apply heat. An Electric Arc Furnace (EAF) uses a raw, high-power electric arc between electrodes and the metal charge itself, making it a powerful tool for melting conductive materials like steel scrap. In contrast, a Plasma Arc Furnace (PAF) uses a specialized torch to generate a controlled, contained jet of ionized gas (plasma), offering more precise temperature control and the versatility to melt a wider range of materials, including non-conductive waste.

While both technologies use electricity to achieve extreme temperatures, the choice between them comes down to a trade-off: The EAF offers brute-force efficiency for large-scale metal recycling, whereas the PAF provides precision, higher temperatures, and material versatility for specialized industrial and environmental applications.

Deconstructing the Electric Arc Furnace (EAF)

An Electric Arc Furnace is the workhorse of modern steel recycling, known for its high power and capacity. Its operation is based on a straightforward and powerful principle.

The Core Principle: Direct Arc Heating

In the most common configuration, a direct arc furnace, massive graphite electrodes are lowered into a chamber filled with scrap metal. A powerful electric current creates an arc that leaps from the electrodes to the conductive metal charge.

The current flows through the scrap, generating intense heat from both the arc itself and the electrical resistance of the metal. This direct exposure melts the charge rapidly and efficiently.

Key Characteristics of EAFs

EAFs are defined by their raw power. The process is famously loud and generates significant electrical fluctuations, dust, and fumes that require extensive management systems.

These furnaces can be powered by either alternating current (AC) or direct current (DC). DC EAFs tend to have lower electrode consumption and less disruptive impact on the power grid.

Typical Applications

The primary application for EAFs is in "mini-mills" for recycling steel scrap. Their ability to melt huge quantities of material quickly makes them indispensable for producing new steel beams, bars, and other structural products from old cars, appliances, and industrial scrap.

Understanding the Plasma Arc Furnace (PAF)

A Plasma Arc Furnace represents a more advanced and controlled evolution of arc-based heating. It doesn't just create an arc; it creates and weaponizes plasma.

The Core Principle: The Plasma Torch

The heart of a PAF is the plasma torch, also known as a plasmatron. Inside the torch, an electric arc is generated in a stream of gas (such as argon, nitrogen, or even air).

This arc superheats the gas, stripping electrons from its atoms and turning it into a focused, high-velocity jet of plasma that can reach temperatures far exceeding a standard electric arc. This controlled plasma jet is then directed at the material to be melted.

The Critical Difference: Transferred vs. Non-Transferred Arc

Plasma torches can operate in two modes, which fundamentally expands their capability beyond an EAF.

In transferred arc mode, the plasma jet establishes an electrical circuit with a conductive charge material. This is highly efficient for melting metals, acting like a super-stable and focused version of a DC EAF.

In non-transferred arc mode, the entire electrical circuit is contained within the torch. The plasma jet simply blasts the material with thermal energy, like a high-temperature blowtorch. This allows the PAF to melt non-conductive materials like soil, asbestos, or medical waste.

Understanding the Trade-offs: EAF vs. PAF

Choosing between these technologies requires a clear understanding of your material, your desired output, and your budget.

Temperature and Control

A PAF offers significantly higher and more stable temperatures than an EAF. The controlled plasma jet allows for precise heating, which is critical for producing specialty alloys or ensuring the complete destruction of hazardous compounds.

Material Versatility

This is a defining difference. EAFs are almost exclusively used for conductive metals like iron and steel. PAFs, thanks to their non-transferred arc capability, can process virtually anything, from exotic metals to hazardous waste, which they can vitrify into a safe, stable glass.

Cost and Complexity

EAF technology is more mature, more common, and generally has a lower capital cost for large-scale operations. PAF systems are more complex, requiring sophisticated plasma torches, gas management systems, and power supplies, leading to higher capital and operational expenses.

Scale and Efficiency

For the specific task of melting bulk steel scrap, the EAF is the undisputed champion of efficiency and scale. Modern EAFs can process hundreds of tons of steel in under an hour. PAFs are typically smaller and used for more specialized, higher-value, or more hazardous applications where brute force is less important than precision.

Making the Right Choice for Your Goal

Ultimately, the furnace is a tool, and you must select the right one for the job.

- If your primary focus is large-scale steel recycling: The EAF is the industry standard, offering unmatched throughput and cost-effectiveness for this specific task.

- If your primary focus is processing hazardous or mixed waste: The PAF is the superior technology, capable of safely destroying and vitrifying a wide range of non-conductive materials.

- If your primary focus is producing high-purity or specialty alloys: The PAF provides the precise temperature and atmospheric control necessary for high-value, sensitive metallurgical processes.

Choosing the correct furnace technology is the first step in ensuring an efficient, safe, and economically viable industrial process.

Summary Table:

| Feature | Electric Arc Furnace (EAF) | Plasma Arc Furnace (PAF) |

|---|---|---|

| Core Principle | Direct arc to conductive metal charge | Controlled plasma jet from a torch |

| Primary Application | Large-scale steel scrap recycling | Hazardous waste treatment, specialty alloys |

| Material Versatility | Conductive materials (e.g., steel) | Conductive & non-conductive materials (e.g., soil, waste) |

| Key Advantage | High throughput, cost-effective for bulk metals | Precise temperature control, material versatility |

Struggling to choose the right furnace technology for your specific materials and goals? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate the trade-offs between brute-force efficiency and precise control to find the perfect solution for your metal recycling, hazardous waste processing, or specialty alloy production. Contact our team today for a personalized consultation and ensure your process is efficient, safe, and economically viable.

Visual Guide

Related Products

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are sputtering systems used for? A Guide to Advanced Thin-Film Deposition

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab

- What are the types of induction melting furnace? Coreless, Channel, and VIM Explained

- What is a sputtering machine? A Guide to High-Quality Thin Film Deposition

- What are the different melting methods? A Guide to Choosing the Right Industrial Furnace