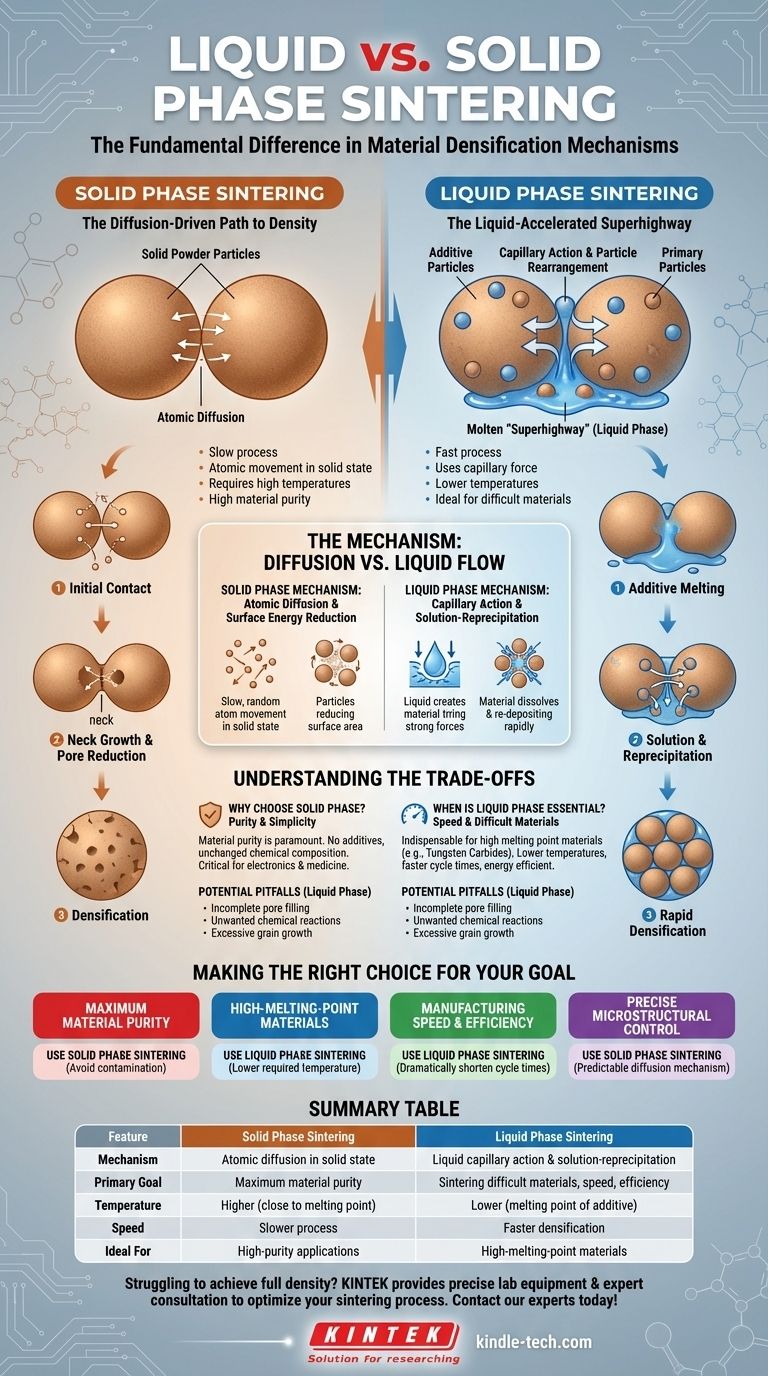

The fundamental difference between liquid and solid phase sintering lies in the state of the materials during the heating process. In solid phase sintering, the entire powder compact remains solid, relying on atomic movement across particle surfaces to bond. Conversely, liquid phase sintering introduces a small amount of an additive that melts, creating a liquid that accelerates the bonding and densification process.

The core distinction is not just the presence of a liquid, but the mechanism it enables. Solid phase sintering is a slow process governed by atomic diffusion, while liquid phase sintering creates a molten "superhighway" that uses capillary force and rapid particle transport to achieve density more quickly and at lower temperatures.

The Mechanism of Solid Phase Sintering

Solid phase sintering is the foundational method for densifying a powder compact without melting the primary material. Its efficiency depends entirely on the movement of atoms in their solid state.

The Foundation: Atomic Diffusion

At high temperatures, atoms in the powder particles become more mobile. They begin to move and diffuse across the boundaries where individual particles touch.

The Goal: Reducing Surface Energy

This atomic movement is driven by a natural tendency to reduce the system's total surface energy. A fine powder has a massive amount of surface area, and by bonding together, the particles form a more stable, lower-energy structure.

The Result: Neck Growth and Pore Reduction

As atoms migrate to the points of contact, they form small bridges, or "necks," between particles. Over time, these necks grow larger, pulling the particles closer together and systematically shrinking the pores or voids between them.

How Liquid Phase Sintering Changes the Game

Liquid phase sintering is an engineered solution to overcome the limitations of the solid phase process, especially for materials that are difficult to sinter.

The Key Ingredient: The Additive

This process begins by mixing the primary powder with a small amount of a secondary powder, often called a sintering aid or binder. This additive is chosen specifically because it has a lower melting point than the main material.

The Liquid's Role: Capillary Action

When the compact is heated to the sintering temperature, the additive melts and flows into the pores between the solid particles. This liquid creates powerful capillary forces that pull the solid particles together, rapidly rearranging them into a much denser packing arrangement.

The Acceleration Factor: Solution and Reprecipitation

The liquid phase acts as a high-speed transport medium. The primary solid particles partially dissolve into the liquid at their points of contact. This dissolved material then travels through the liquid and re-precipitates in the neck regions between particles, efficiently filling voids and dramatically accelerating densification.

Understanding the Trade-offs

Choosing between these two methods involves a clear set of trade-offs related to material properties, process efficiency, and final component requirements.

Why Choose Solid Phase? Purity and Simplicity

Solid phase sintering is the ideal choice when material purity is paramount. Since no additives are introduced, the final component's chemical composition is unchanged. This is critical for applications in electronics, medicine, and research where even trace contaminants are unacceptable.

When is Liquid Phase Essential? Speed and Difficult Materials

This method is indispensable for materials with extremely high melting points or poor atomic diffusion, such as tungsten carbides and many advanced ceramics. The liquid phase allows for sintering at significantly lower temperatures and in much shorter times, making the process more energy-efficient and commercially viable.

Potential Pitfalls of Liquid Phase

The presence of a liquid introduces complexity. There is a risk of incomplete pore filling, unwanted chemical reactions between the liquid and solid particles, or excessive grain growth, which can negatively impact the final mechanical properties of the component.

Making the Right Choice for Your Goal

Your final decision should be guided by the primary objective for your component and manufacturing process.

- If your primary focus is maximum material purity: Use solid phase sintering to avoid any contamination from secondary additives.

- If your primary focus is sintering high-melting-point materials: Use liquid phase sintering to lower the required temperature and make the process feasible.

- If your primary focus is manufacturing speed and energy efficiency: Use liquid phase sintering to dramatically shorten cycle times and reduce costs.

- If your primary focus is precise microstructural control in a single-component system: Use solid phase sintering for its predictable, diffusion-controlled mechanism.

Ultimately, understanding this core difference empowers you to select the most effective and efficient path to achieving full material density.

Summary Table:

| Feature | Solid Phase Sintering | Liquid Phase Sintering |

|---|---|---|

| Mechanism | Atomic diffusion in solid state | Liquid capillary action & solution-reprecipitation |

| Primary Goal | Maximum material purity | Sintering difficult materials, speed, efficiency |

| Temperature | Higher (close to material's melting point) | Lower (melting point of the additive) |

| Speed | Slower process | Faster densification |

| Ideal For | High-purity applications (electronics, medicine) | High-melting-point materials (tungsten carbide, ceramics) |

Struggling to achieve full density with your powder materials? The choice between solid and liquid phase sintering is critical for your component's performance and manufacturing efficiency. KINTEK specializes in providing the precise lab equipment and expert consultation needed to optimize your sintering process. Whether you require high-purity results or need to sinter challenging materials efficiently, we have the solutions. Contact our experts today to discuss how we can enhance your laboratory's capabilities and help you select the perfect sintering path for your goals.

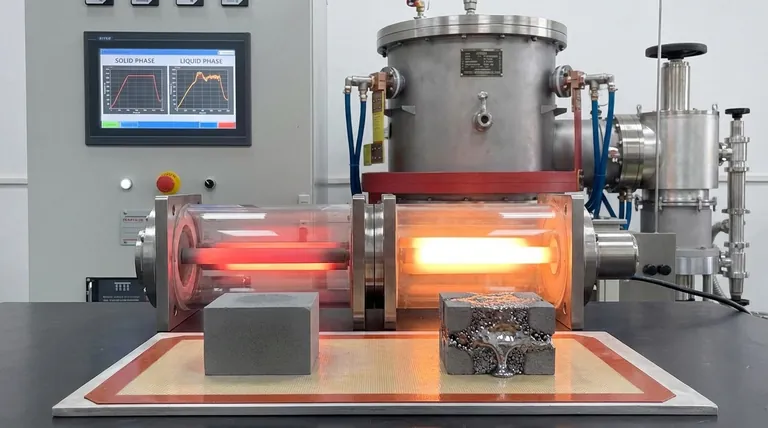

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the dangers of pyrolysis? Managing Environmental, Operational, and Chemical Risks

- What is the pressure less sintering method? Achieve Complex Shapes Without High-Pressure Equipment

- Why is an ultra-high temperature furnace (1800°C) required for Si-O-C ceramics carbothermal reduction?

- What are the three most important factors in material heat treatment? Master Temperature, Time, and Cooling for Superior Properties

- Why is a molecular pump vacuum system necessary for titanium matrix composites? Achieve $1 \times 10^{-3}$ Pa High Purity

- What is the main purpose of quenching? Achieve Precise Hardness and Strength in Metals

- What is the difference between vacuum cast and vacuum form? Choose the Right Process for Your Prototype

- What is the purpose of using a vacuum drying oven for graphite electrode sheets? Ensure Battery Safety & Performance