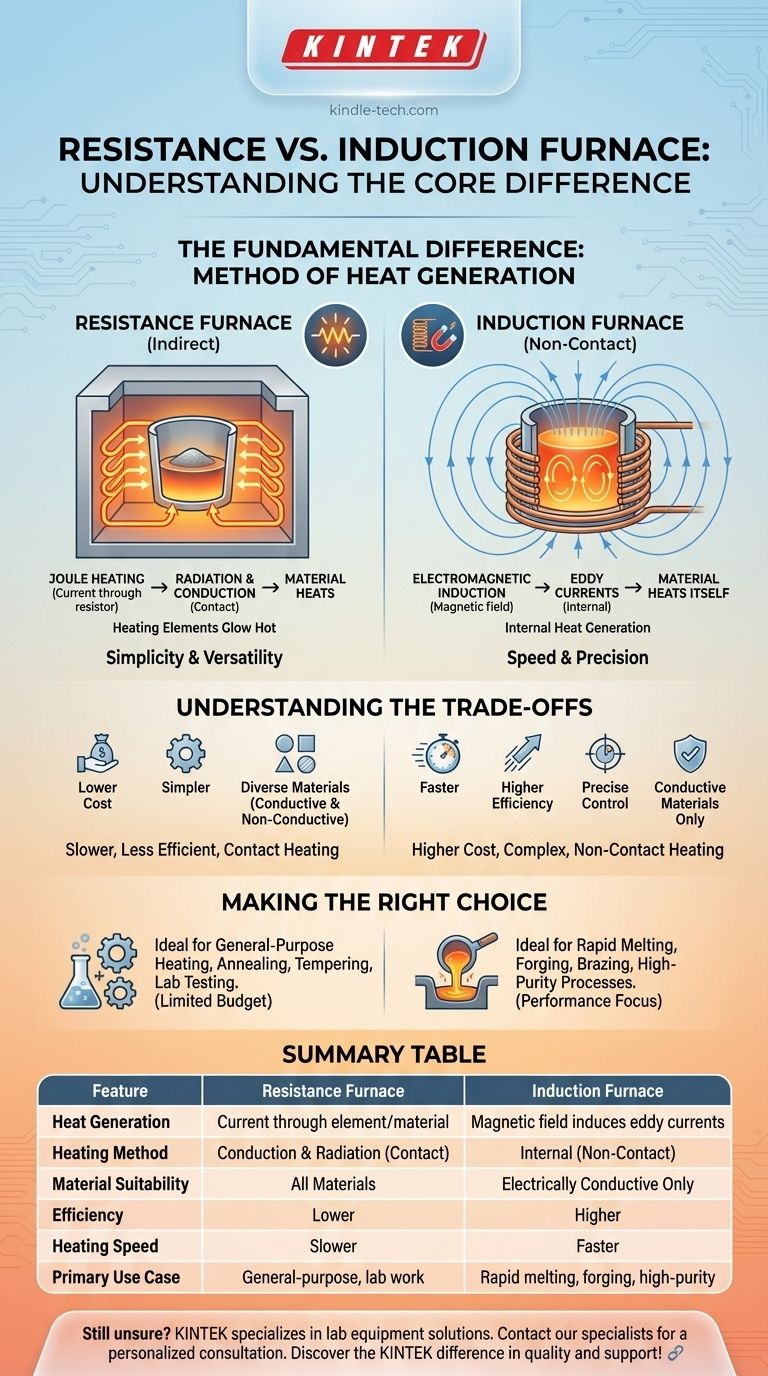

The fundamental difference between a resistance and an induction furnace is the method of heat generation. A resistance furnace works by passing an electrical current through a high-resistance material—either the object itself or a separate heating element—which glows hot and transfers heat. An induction furnace, in contrast, uses a non-contact method, creating a powerful magnetic field to generate heat directly inside the conductive material.

While both are types of electric furnaces, the core distinction is how they deliver energy. A resistance furnace uses conduction and radiation from a hot element, while an induction furnace uses an electromagnetic field to make the material heat itself from within. This single difference dictates their efficiency, speed, and ideal applications.

The Principle of Resistance Heating

Resistance heating is a straightforward and widely used technology. Its operation is based on a fundamental principle of physics.

How It Works: Joule Heating

The core principle is Joule's first law. When an electric current passes through a conductor, it generates heat due to the resistance of that conductor.

This is the same effect that makes the coils in an electric toaster or a space heater glow red-hot. The amount of heat is directly proportional to the resistance and the square of the current.

Direct vs. Indirect Heating

There are two primary methods of applying this principle:

- Indirect Resistance Heating: This is the most common form. Current is passed through dedicated heating elements made of high-resistance material. These elements become extremely hot and transfer their heat to the furnace chamber and the material (the "charge") through radiation and convection.

- Direct Resistance Heating: In this method, the material to be heated acts as the resistor itself. Electrodes are attached directly to the charge, and a large current is passed through it, causing it to heat up from within. This is less common and is only suitable for conductive materials.

The Principle of Induction Heating

Induction heating is a more advanced, non-contact heating process. It relies on the principles of electromagnetism to generate heat with remarkable speed and precision.

How It Works: Electromagnetic Induction

An induction furnace uses a powerful coil, typically made of copper, through which a high-frequency alternating current (AC) is passed.

This current generates a strong, rapidly changing magnetic field in the space within and around the coil.

The Role of Eddy Currents

When a conductive material, such as a piece of metal, is placed within this magnetic field, the field induces circular electric currents inside the material. These are known as eddy currents.

These eddy currents flow against the material's own electrical resistance, generating intense, localized heat. The material effectively becomes its own heating element, allowing for extremely fast and uniform heating from the inside out.

Understanding the Trade-offs

Neither technology is universally superior; the right choice depends entirely on the application, material, and desired outcome.

Resistance Furnace: Simplicity vs. Inefficiency

The primary advantages of resistance furnaces are their simplicity and lower initial cost. They can be used to heat a vast range of materials, including non-conductors.

However, they are often less energy-efficient. Heat must first be generated in the elements and then transferred to the charge, resulting in heat loss to the furnace structure and atmosphere. They also have slower startup times and less precise temperature control.

Induction Furnace: Precision vs. Complexity

Induction furnaces offer unparalleled speed, efficiency, and control. Since heat is generated directly within the material, energy transfer is highly efficient with minimal heat loss. This allows for rapid heating cycles and precise temperature management.

The main trade-offs are higher initial cost and complexity. Furthermore, induction heating is only effective on electrically conductive materials, making it unsuitable for ceramics, glass, or other insulators.

Making the Right Choice for Your Goal

To select the correct technology, you must first define your most critical process requirement.

- If your primary focus is general-purpose heating for diverse materials on a limited budget: A resistance furnace is the more straightforward and economical choice for applications like annealing, tempering, or lab testing.

- If your primary focus is rapid, high-purity, and efficient melting or heating of conductive metals: An induction furnace provides superior performance, control, and operational efficiency for tasks like metal melting, forging, and brazing.

Ultimately, understanding this core mechanism—contact heating versus contactless induction—is the key to selecting the most effective technology for your specific process.

Summary Table:

| Feature | Resistance Furnace | Induction Furnace |

|---|---|---|

| Heat Generation | Current through heating element or material | Magnetic field induces eddy currents in material |

| Heating Method | Conduction & Radiation (Contact) | Internal (Non-Contact) |

| Material Suitability | All Materials (Conductive & Non-Conductive) | Electrically Conductive Materials Only |

| Efficiency | Lower (Heat loss to surroundings) | Higher (Direct internal heating) |

| Heating Speed | Slower | Faster |

| Primary Use Case | General-purpose heating, annealing, lab work | Rapid melting, forging, high-purity processes |

Still unsure which furnace technology is right for your application?

KINTEK specializes in providing the perfect lab equipment solutions. Our experts can help you analyze your specific needs—whether you require the versatility of a resistance furnace or the high-speed precision of an induction furnace—to ensure optimal performance and efficiency for your laboratory.

Contact our specialists today for a personalized consultation and discover the KINTEK difference in quality and support!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing