At their core, the fundamental difference between Rockwool and ceramic fiber is their maximum service temperature and material composition. Rockwool is a mineral wool insulation made from natural stone, effective for moderate heat applications, while ceramic fiber is a synthetic refractory material engineered for extreme heat environments.

The choice is not about which is "better," but which is correct for your specific temperature range. Rockwool is the standard for applications up to approximately 600°C (1112°F), whereas ceramic fiber is the required choice for extreme-heat environments like kilns and forges, regularly exceeding 1200°C (2200°F).

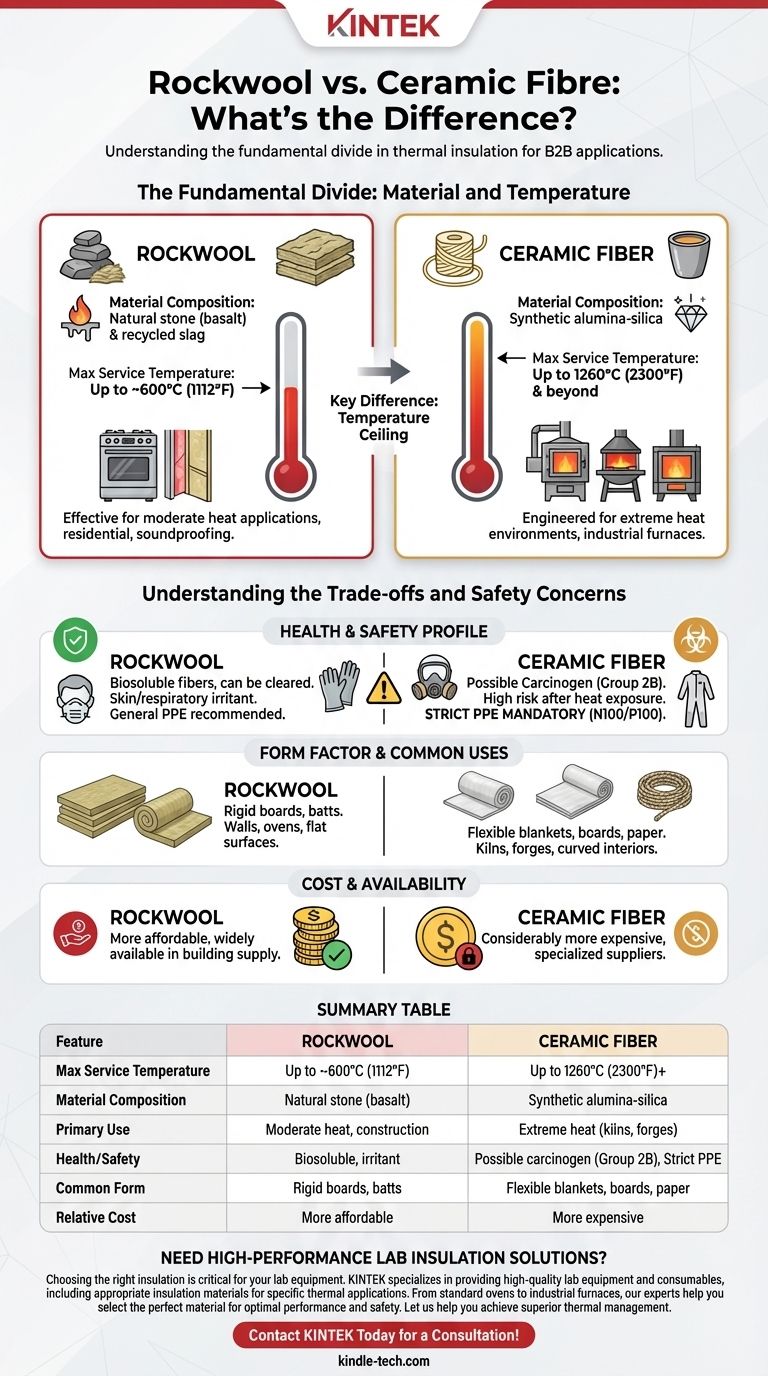

The Fundamental Divide: Material and Temperature

To select the right material, you must first understand what they are and what thermal loads they are designed to withstand.

What is Rockwool?

Rockwool, also known as stone wool or mineral wool, is a type of insulation made by melting basalt rock and recycled slag and spinning the molten mixture into fine fibers.

These fibers are then compressed into dense mats or batts. Its primary purpose is thermal and acoustic insulation in residential construction and for moderate-temperature industrial applications.

The key limitation is its temperature ceiling. While excellent for many uses, Rockwool begins to lose its structural integrity and insulating properties at temperatures above approximately 600°C - 650°C (1112°F - 1200°F).

What is Ceramic Fiber?

Ceramic fiber is a high-performance refractory material, also known as Refractory Ceramic Fiber (RCF) or Alumina Silicate Wool. It is synthetically produced by melting high-purity alumina and silica.

This material is engineered specifically for extreme heat. Standard ceramic fiber blankets are typically rated for continuous use at 1260°C (2300°F), with high-purity grades capable of handling even higher temperatures.

Because of this thermal resistance, it is the default material for lining industrial furnaces, kilns, forges, and other high-temperature processing equipment.

Understanding the Trade-offs and Safety Concerns

Beyond temperature, the materials differ significantly in safety profile, cost, and form factor. These are critical considerations for any project.

Health and Safety Profile

Both materials release airborne fibers when cut or handled, necessitating proper Personal Protective Equipment (PPE). However, their long-term health risks are different.

Rockwool fibers are generally considered biosoluble, meaning they can be cleared by the body over time. While they are a skin and respiratory irritant, they are not typically classified as a long-term carcinogenic risk.

Refractory Ceramic Fibers (RCF), on the other hand, are classified by the IARC as a Group 2B substance—"possibly carcinogenic to humans." After being exposed to high heat, these fibers can become more brittle and hazardous to inhale. Strict safety protocols, including a high-quality respirator (N100/P100), are mandatory when handling ceramic fiber.

Form Factor and Common Uses

Rockwool is most commonly found as rigid or semi-rigid boards and flexible batts, making it ideal for insulating walls, ovens, and enclosures with flat surfaces.

Ceramic fiber is most frequently sold as a flexible blanket. This form factor is perfect for lining the curved or irregular interiors of forges and kilns or for wrapping high-temperature pipes and exhaust systems. It is also available in rigid boards, paper, and rope forms.

Cost and Availability

Rockwool is a widely produced industrial and construction material. It is significantly more affordable and can often be found at specialized building supply centers.

Ceramic fiber is a specialized industrial product. It is considerably more expensive and must be purchased from refractory material suppliers.

Making the Right Choice for Your Application

Your decision hinges almost entirely on the maximum operating temperature of your project.

- If your application operates below 600°C (1112°F): Rockwool is the safer, more economical, and more readily available choice for ovens, smokers, soundproofing, and general fire-blocking.

- If your application will exceed 650°C (1200°F): Ceramic fiber is the only appropriate option. This is mandatory for building or relining forges, kilns, foundry furnaces, and other extreme-heat equipment.

- If your primary focus is safety in a high-heat context: When ceramic fiber is required, strictly adhere to all safety guidelines. For new projects, investigate modern low-bio persistence (LBP) or "biosoluble" fiber alternatives, which offer similar temperature resistance with an improved safety profile.

By matching the material's capabilities to your project's demands, you ensure both safe and effective thermal performance.

Summary Table:

| Feature | Rockwool | Ceramic Fiber |

|---|---|---|

| Max Service Temperature | Up to ~600°C (1112°F) | Up to 1260°C (2300°F) and beyond |

| Material Composition | Natural stone (basalt) | Synthetic alumina-silica |

| Primary Use | Moderate heat applications, construction | Extreme heat environments (kilns, forges) |

| Health/Safety | Biosoluble fibers, irritant | Possible carcinogen (Group 2B), requires strict PPE |

| Common Form | Rigid boards, batts | Flexible blankets, boards, paper |

| Relative Cost | More affordable | More expensive |

Need High-Performance Lab Insulation Solutions?

Choosing the right insulation is critical for the safety and efficiency of your laboratory equipment. KINTEK specializes in providing high-quality lab equipment and consumables, including the appropriate insulation materials for your specific thermal applications.

Whether you're insulating an industrial furnace, a kiln, or a standard laboratory oven, our experts can help you select the perfect material to ensure optimal performance and safety.

Let us help you achieve superior thermal management. Contact KINTEL today for a consultation!

Visual Guide

Related Products

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Custom Boron Nitride (BN) Ceramic Parts

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What factors affect the resistance of a heating element? Master the 4 Key Variables for Precise Thermal Design

- Why must YAG:Ce powder from aerosol pyrolysis undergo thermal annealing? Unlock Peak Phosphor Performance

- What is the temperature limit of silicon carbide? Maximize Performance from 1600°C to 2500°C

- What is the working temperature of a heating element? Match Material to Your Application's Heat Needs

- What are the heating elements for high temperature furnaces? Select the Right Element for Your Atmosphere

- How do you control the temperature of a heating element? Master On/Off, Proportional, and PID Methods

- What determines the size of a heating element? Key Factors for Optimal Performance & Lifespan

- Is tungsten a good heating element? Unlock Extreme Temperatures in Vacuum Environments