At its core, vacuum casting is a low-volume production method using soft silicone molds and polyurethane resins, while injection molding is a mass-production process using hard steel molds and thermoplastic pellets. Vacuum casting is optimized for speed and fidelity in small batches, making it ideal for prototyping. Injection molding is optimized for cost-efficiency and repeatability at high volumes, making it the standard for consumer products.

The fundamental difference isn't about which process is "better," but which is appropriate for your specific stage of product development. Vacuum casting is for validation and low-volume runs; injection molding is for scaling production into the thousands or millions.

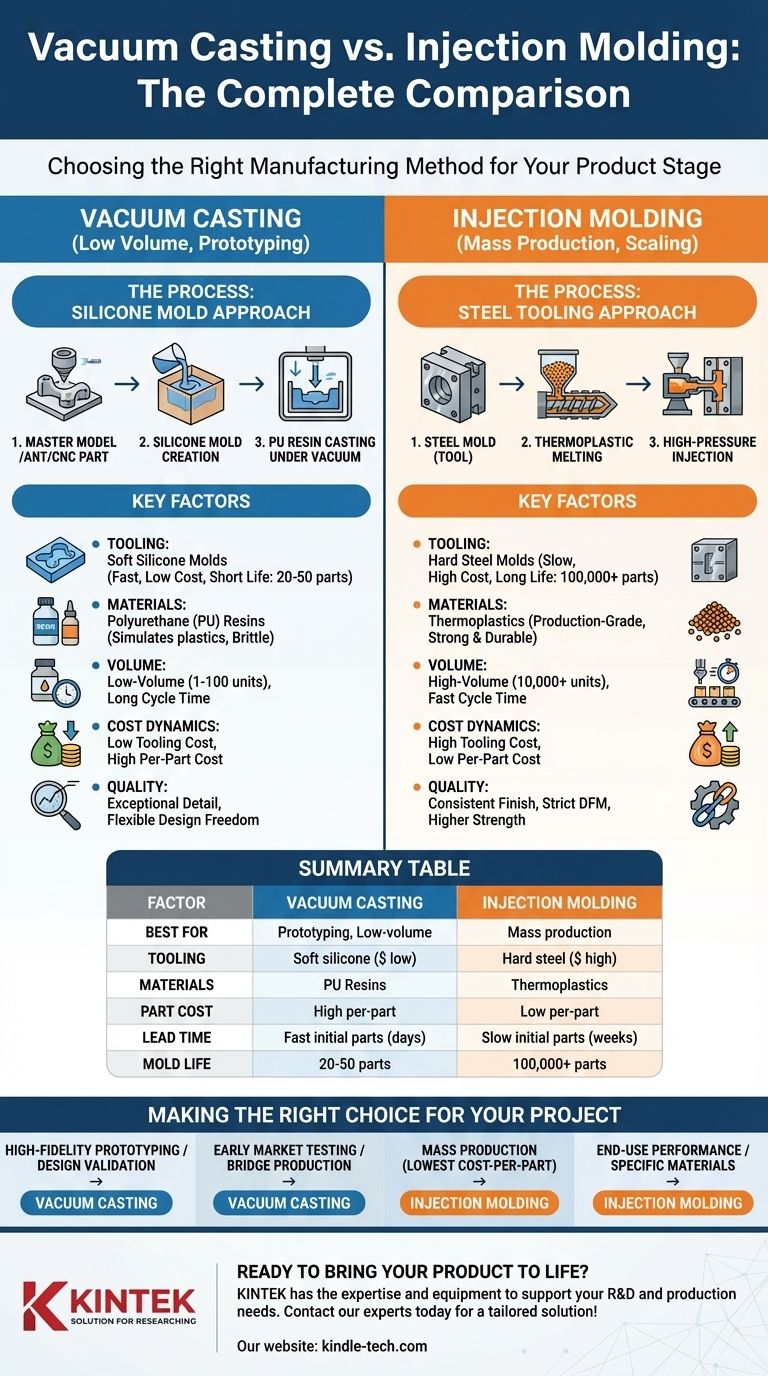

The Core Process: How Each Method Works

To understand the trade-offs, you must first understand the fundamental mechanics of each process. Their differences in tooling and materials dictate their respective strengths and weaknesses.

Vacuum Casting: The Silicone Mold Approach

Vacuum casting is a three-step process. First, a high-quality master model is created, typically using 3D printing (SLA or PolyJet) or CNC machining.

Second, this master model is suspended inside a casting box, and liquid silicone is poured around it. Once cured, the box is removed and the silicone is cut open to create a two-part mold, revealing a highly detailed negative cavity.

Finally, the silicone mold is placed in a vacuum chamber. Two-part polyurethane (PU) resins are mixed and poured into the mold. The vacuum removes all air bubbles from the liquid resin, ensuring it perfectly fills every detail of the mold cavity. The part then cures inside the mold.

Injection Molding: The Steel Tooling Approach

Injection molding is a high-pressure, high-temperature process. It begins with the creation of a robust, two-part metal mold, or "tool," typically machined from steel or aluminum. This tooling is a complex engineering project in itself and can take weeks or months to create.

Once the tool is complete, it is mounted in an injection molding machine. Small plastic pellets (thermoplastics) are melted into a liquid state and then injected at extremely high pressure into the mold cavity.

The mold is cooled, causing the plastic to solidify into the desired shape. The mold then opens, and the finished part is ejected by pins. This entire cycle can take as little as a few seconds.

Comparing Key Production Factors

The differences in process lead to vastly different outcomes in terms of cost, speed, and material options.

Tooling: Soft Silicone vs. Hard Steel

Vacuum casting uses soft silicone molds. These are inexpensive and can be created in just a few days. However, they have a very limited lifespan, typically degrading after producing just 20 to 50 parts.

Injection molding requires hard steel or aluminum molds. These are extremely durable and can produce hundreds of thousands or even millions of parts. The trade-off is immense: they are very expensive (from tens of thousands to hundreds of thousands of dollars) and take weeks or months to manufacture.

Materials: Polyurethane Resins vs. Thermoplastics

Vacuum casting almost exclusively uses polyurethane (PU) resins. These are thermosetting polymers that cure through an irreversible chemical reaction. They are formulated to simulate the properties of common production plastics like ABS, nylon, or polypropylene, but they are not the real thing.

Injection molding uses a vast library of thermoplastics. These are the actual production-grade materials you find in final products. They can be repeatedly melted and solidified, and their mechanical properties are well-understood and highly consistent.

Volume and Speed: Low vs. High

Vacuum casting is ideal for low volumes, from a single prototype up to around 100 units. While the tooling is fast to make, the cycle time per part is long (minutes to hours) due to the resin's curing time.

Injection molding is built for high volumes, typically from 10,000 parts into the millions. The initial tooling setup is slow, but the per-part cycle time is incredibly fast (often just seconds), making it unbeatable for mass production.

Cost Dynamics: Upfront vs. Per-Part

With vacuum casting, the tooling cost is very low, but the cost-per-part is relatively high due to the materials and manual labor involved. This makes it economical for small batches.

With injection molding, the tooling cost is extremely high, but the cost-per-part is exceptionally low at scale. The massive upfront investment is amortized over the huge production run, making it highly economical for mass-market products.

Understanding the Trade-offs: Quality and Fidelity

Your choice also depends on the specific quality attributes and design freedom your project requires.

Detail and Surface Finish

Vacuum casting excels at producing parts with exceptional surface finish and fine detail. The liquid silicone captures every minute feature of the master model, resulting in parts that often look like a finished product straight out of the mold.

Injection molding can also produce high-quality finishes, but it is more susceptible to cosmetic defects like sink marks, flash, or weld lines. Achieving a perfect finish requires careful tool design and process control.

Part Strength and Material Properties

Injection molded parts are generally stronger and more durable. They are made from true engineering thermoplastics with predictable, well-documented mechanical and thermal properties.

Vacuum cast parts, made from PU resins, simulate these properties but may not match the exact performance, long-term stability, or impact resistance of their injection-molded counterparts. They can sometimes be more brittle.

Design Freedom and Limitations

Vacuum casting offers greater design freedom. The flexible silicone mold allows for parts with complex geometries and undercuts without requiring expensive and complex mold mechanisms. The mold can simply be cut or flexed to de-mold the part.

Injection molding requires strict adherence to Design for Manufacturing (DFM) principles. Features like draft angles, uniform wall thickness, and ribs are critical to ensure the part can be ejected from the rigid steel mold without damage. Undercuts require complex side-actions or lifters, which add significant cost and complexity to the tool.

Making the Right Choice for Your Project

Choosing between these two methods is a strategic decision based on your project's goals, budget, and development stage.

- If your primary focus is high-fidelity prototyping and design validation: Use vacuum casting for its speed, low cost for small batches (1-50 units), and excellent aesthetic quality.

- If your primary focus is early market testing or bridge production: Use vacuum casting to produce a few hundred units quickly to generate revenue or feedback while your expensive injection mold is being manufactured.

- If your primary focus is mass production at the lowest cost-per-part: Choose injection molding, as it is the only method that can economically produce thousands or millions of identical parts.

- If your primary focus is end-use performance with specific materials: You must use injection molding to access the full range of production-grade thermoplastics and their certified properties.

By aligning your manufacturing method with your production volume and development goals, you empower your project for both cost-efficiency and success.

Summary Table:

| Factor | Vacuum Casting | Injection Molding |

|---|---|---|

| Best For | Prototyping, Low-volume (1-100 units) | Mass production (10,000+ units) |

| Tooling | Soft silicone molds ($ low, 1-3 days) | Hard steel molds ($ high, weeks-months) |

| Materials | Polyurethane resins (simulates plastics) | Production-grade thermoplastics |

| Part Cost | High per-part, low tooling cost | Low per-part, high tooling cost |

| Lead Time | Fast initial parts (days) | Slow initial parts (weeks), fast cycle time |

| Mold Life | 20-50 parts | 100,000+ parts |

Ready to bring your product to life? Whether you need high-fidelity prototypes for design validation via vacuum casting or are scaling up to mass production with injection molding, KINTEK has the expertise and equipment to support your laboratory's R&D and production needs. Our team specializes in helping you select the right manufacturing process to balance cost, speed, and quality effectively.

Contact our experts today to discuss your project requirements and get a tailored solution!

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing

- What is a pyrolysis process? Transform Waste into Energy and Valuable Materials

- What is the function of a high-frequency induction plasma reactor? Synthesis of Nano-scale Magnéli Phase Titanium Oxide

- What is the purpose of vacuum heating equipment in HT-Na₃PS₄ preparation? Optimize Your Electrolyte Conductivity

- How does temperature affect sintering? Master the Thermal Sweet Spot for Dense, Strong Parts

- How does a condensation column with a temperature gradient function? Master High-Purity Metal Distillation

- Can you braze stainless steel with MAPP gas? Yes, with the right flux and technique.

- What is the temperature of vacuum brazing? Achieve Perfect Joints Without Compromising Your Materials