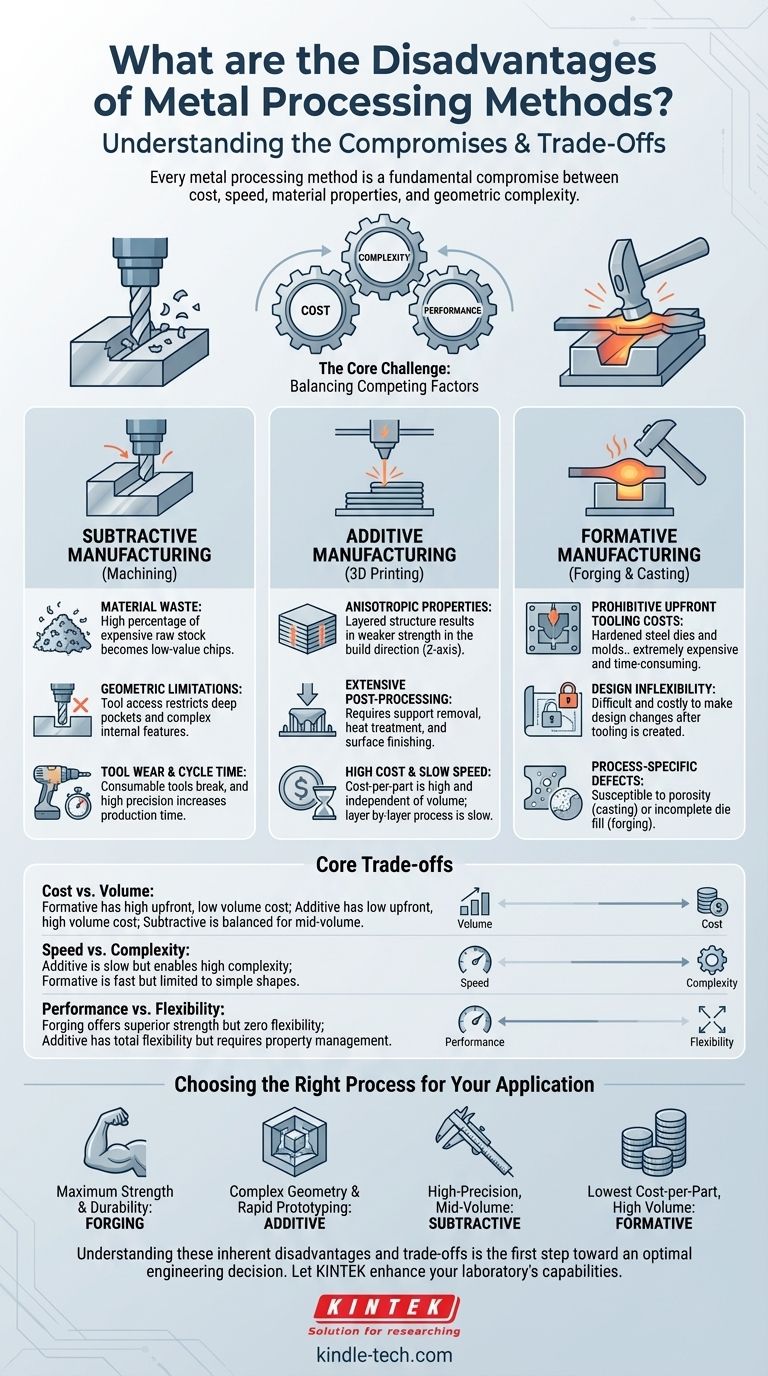

The primary disadvantage of any metal processing method is that it represents a fundamental compromise. No single method excels in all areas; each forces a trade-off between critical factors like production cost, speed, the final material properties of the part, and the geometric complexity that can be achieved.

The core challenge in metal manufacturing is not finding a "perfect" process, but selecting the process with the right set of limitations for your specific application, budget, and production volume.

A Framework for Understanding Disadvantages

To understand the specific disadvantages, it's best to group methods into three main categories: subtractive, additive, and formative manufacturing. Each category has a distinct profile of inherent drawbacks.

The Disadvantages of Subtractive Manufacturing (Machining)

Subtractive processes, like CNC milling and turning, create a final shape by cutting material away from a solid block (a billet or blank).

Material Waste

The most obvious disadvantage is wasted material. The metal chips removed during machining have significantly lower value than the raw stock, representing a direct and often substantial cost. This is especially painful when working with expensive materials like titanium or specialty alloys.

Geometric Limitations

A part's geometry is limited by the physical access of the cutting tool. Creating deep, narrow pockets or complex internal features (undercuts) can be difficult or impossible, requiring multiple setups or specialized machinery that increases cost and time.

Tool Wear and Cycle Time

Cutting tools are consumable items that wear down and break, representing a continuous operational cost. Furthermore, achieving high precision or complex features often requires long machining cycles, which can make the cost-per-part too high for large-scale production.

The Disadvantages of Additive Manufacturing (3D Printing)

Additive processes, like Direct Metal Laser Sintering (DMLS) or Electron Beam Melting (EBM), build parts layer-by-layer from a metal powder.

Anisotropic Material Properties

Because parts are built in layers, their mechanical properties can be anisotropic—meaning they are stronger in the X-Y plane than they are in the Z-axis (the build direction). This can be a critical point of failure and must be accounted for in engineering design.

Extensive Post-Processing

A "printed" metal part is rarely a finished part. It typically requires multiple post-processing steps, including removal from the build plate, removal of support structures, heat treatment to relieve internal stresses, and surface machining or polishing to achieve desired tolerances and finish. Each step adds time and cost.

High Cost and Slow Speed for Volume

The cost-per-part in metal additive manufacturing is largely independent of volume. This makes it ideal for one-off prototypes but economically unviable for mass production compared to formative methods. The layer-by-layer process is also inherently slow.

The Disadvantages of Formative Manufacturing (Forging & Casting)

Formative processes, like forging, casting, and stamping, use force or heat to shape metal into a desired form without removing material.

Prohibitive Upfront Tooling Costs

This is the single biggest barrier. Creating the hardened steel dies for forging or the molds for casting is extremely expensive and time-consuming. These high initial costs can only be justified by amortizing them over very high production volumes (thousands or millions of parts).

Design Inflexibility

Once a die or mold is created, making design changes is incredibly difficult and expensive, if not impossible. This makes formative processes completely unsuitable for prototyping or iterative design where requirements may change.

Process-Specific Defects

Each formative process has a unique set of potential flaws. Casting is susceptible to porosity (trapped gas bubbles) and shrinkage, while forging can suffer from incomplete die fill or undesirable surface scaling. These require rigorous process control to mitigate.

Understanding the Core Trade-offs

The choice of method is a balancing act between three competing factors: Cost, Complexity, and Performance.

Cost vs. Volume

Formative processes have a massive upfront cost but the lowest cost-per-part at high volume. Additive has a very low upfront cost but a high, flat cost-per-part. Subtractive machining sits in the middle, offering a balance for low-to-mid volume production.

Speed vs. Complexity

Additive manufacturing can produce almost any geometry imaginable, but the build process is slow. Formative processes like stamping are incredibly fast in production but are limited to relatively simple shapes.

Performance vs. Flexibility

Forging produces parts with superior strength due to its controlled grain flow, but it offers zero design flexibility once the tooling is made. Additive offers total design flexibility but can result in weaker, anisotropic material properties that require careful management.

Choosing the Right Process for Your Application

Answering "which method is best?" begins with defining your project's most critical priority.

- If your primary focus is maximum material strength and durability: Forging is often the superior choice for parts that can be forged, as it produces an ideal grain structure.

- If your primary focus is complex geometry or rapid prototyping: Additive manufacturing is the unmatched solution, allowing for geometries no other method can produce.

- If your primary focus is high-precision and a good surface finish for low-to-mid volume: Subtractive manufacturing (CNC machining) remains the industry standard.

- If your primary focus is the lowest possible cost-per-part at very high volumes: Formative processes like casting or stamping are the most economical choice by far.

Understanding these inherent disadvantages and trade-offs is the first step toward making an optimal engineering decision.

Summary Table:

| Manufacturing Method | Primary Disadvantages | Key Trade-Offs |

|---|---|---|

| Subtractive (e.g., CNC Machining) | High material waste, geometric limitations, tool wear | Cost vs. Precision |

| Additive (e.g., Metal 3D Printing) | Anisotropic properties, extensive post-processing, slow for volume | Complexity vs. Speed |

| Formative (e.g., Forging, Casting) | High upfront tooling costs, design inflexibility, process-specific defects | Performance vs. Flexibility |

Struggling to choose the right metal processing method for your lab's specific needs? At KINTEK, we specialize in providing tailored lab equipment and consumables that help you navigate these critical trade-offs. Whether you require precision machining tools, advanced additive manufacturing systems, or reliable formative processing equipment, our experts are here to ensure you achieve optimal material properties, cost-efficiency, and geometric complexity.

Let KINTEK enhance your laboratory's capabilities—contact us today for a personalized consultation!

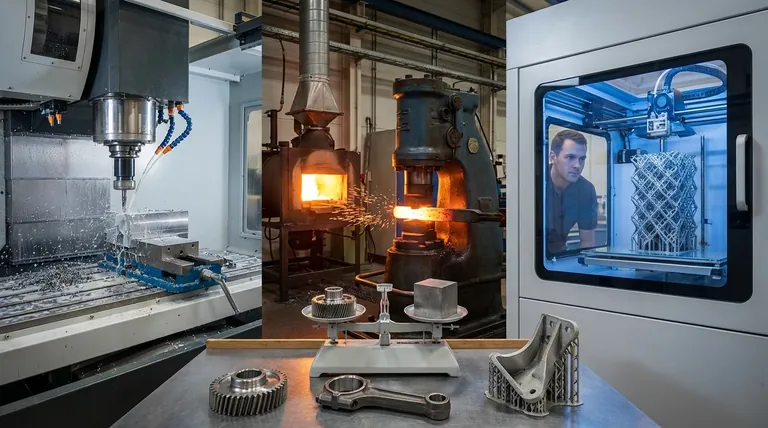

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Double Plate Heating Press Mold for Lab

People Also Ask

- Does liquid pressure depend on the size and shape of the container? Discover the Hydrostatic Paradox.

- What are the 3 types of biomass energy sources? Unlock the Potential of Organic Materials

- What is the electric arc furnace? A Sustainable Solution for Modern Steel Recycling

- What are the advantages of brazing compared to welding? Achieve Clean, Low-Distortion Metal Joining

- What is slow and fast pyrolysis? Choosing the Right Process for Bio-Oil or Biochar

- Why are high-energy homogenizers required for high-performance microbial biopolymers? Achieving Superior Dispersion

- Why is sputtering done in SEM? Prevent Charging and Get Clear Images of Non-Conductive Samples

- What happens in sputtering? A Step-by-Step Guide to Thin Film Deposition